|

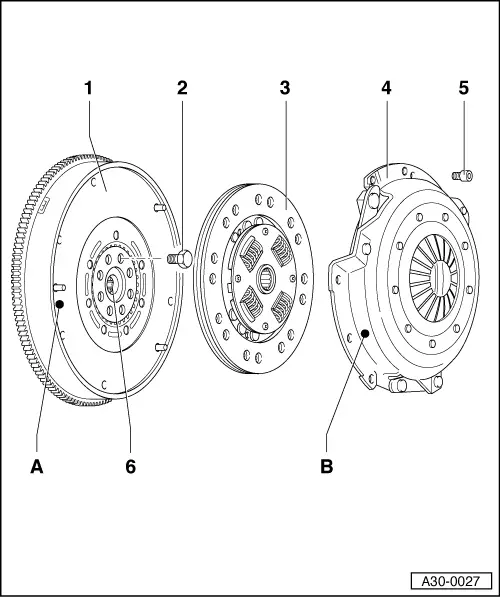

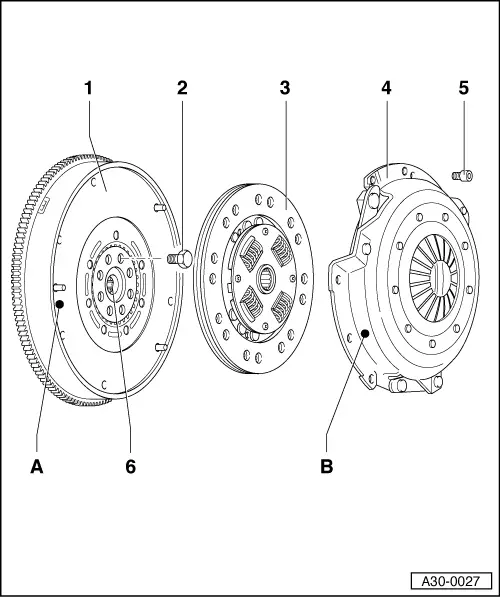

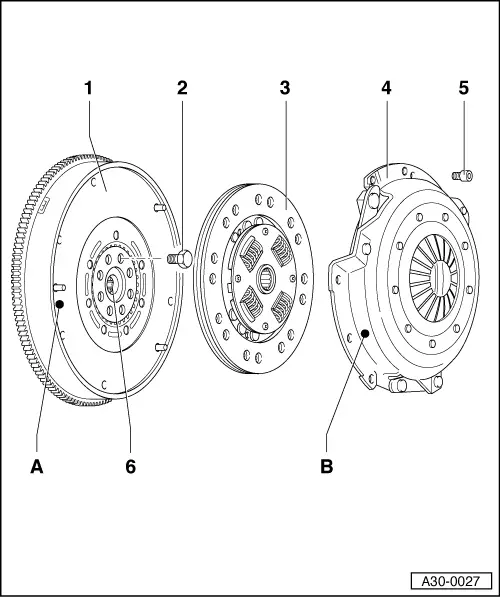

Servicing clutch

Servicing clutch

Special tools, testers and auxiliary items required:

-

◆ Retainer 10-201

-

◆ Mandrel 3176

-

◆ Grease G 000 100

Notes:

-

◆ Observe general repair instructions

.

-

◆ Before renewing the clutch plate and pressure plate

=> Fault-finding No. 9 - Defects on the clutch and clutch mechanism

-

◆ Replace clutch plates and pressure plates with damaged or loose rivets.

-

◆ Select the correct clutch plate and pressure plate according to engine code:

=> Parts catalogue

-

◆ Clean input shaft splines and (in the case of used clutch plates) the hub splines. Remove corrosion and apply only a very thin coating of grease G 000 100 to the splines. Then move clutch plate to and fro on input shaft until hub moves freely on shaft. Excess grease must be removed.

-

◆ Pressure plates have an anti-corrosion coating and are greased. Only the contact surface may be cleaned, otherwise the service life of the clutch will be considerably reduced.

-

◆ If the clutch has burnt out, thoroughly clean the bellhousing, flywheel and parts of the engine facing the gearbox to reduce the smell of burnt linings.

|