A4 Mk1

|

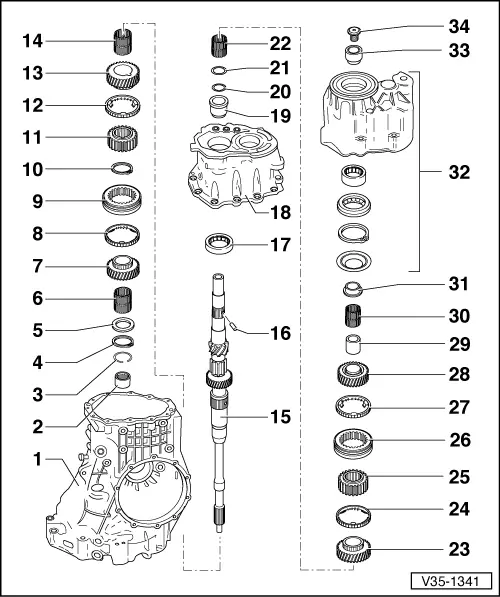

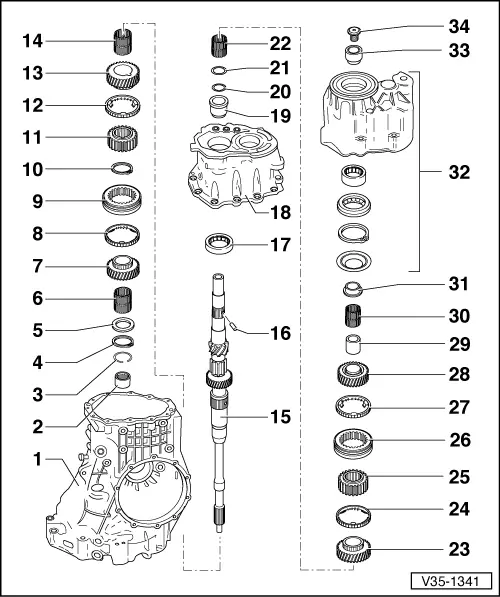

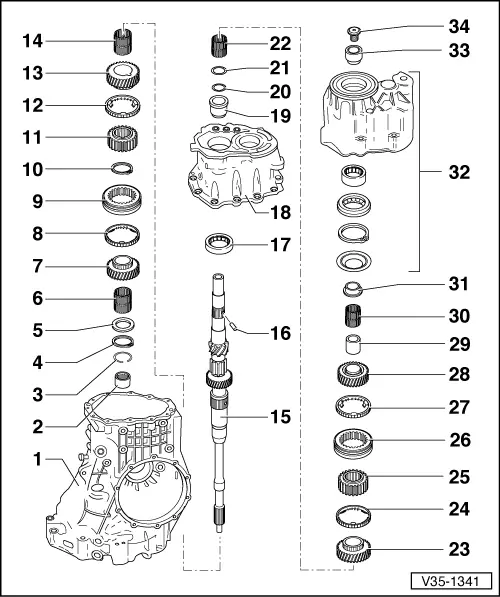

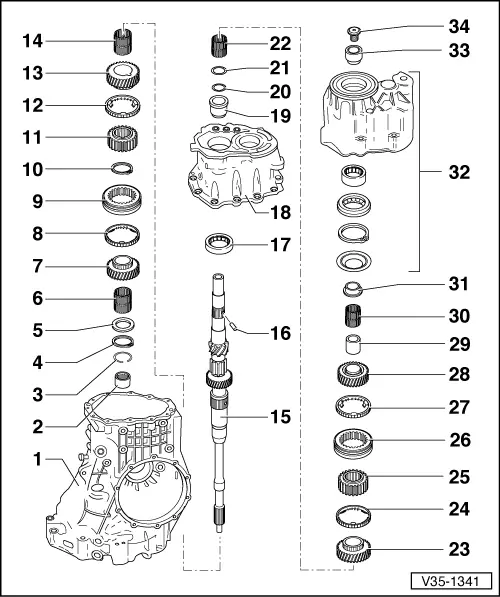

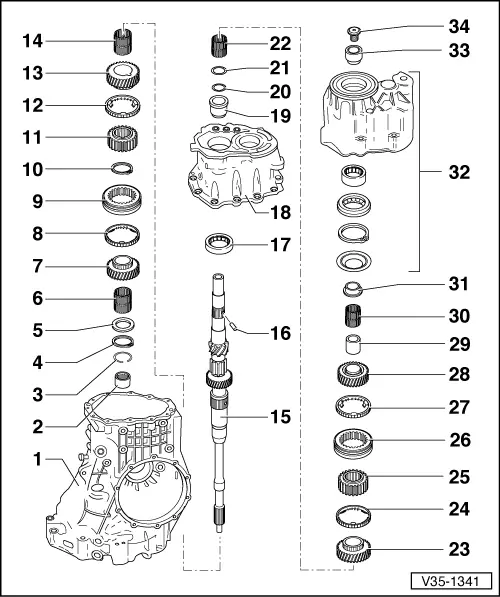

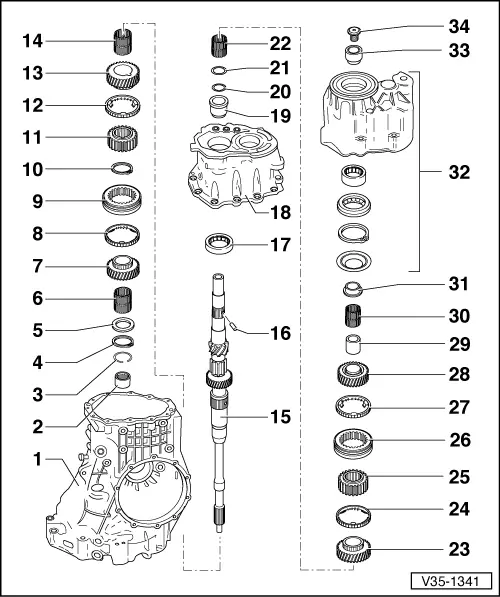

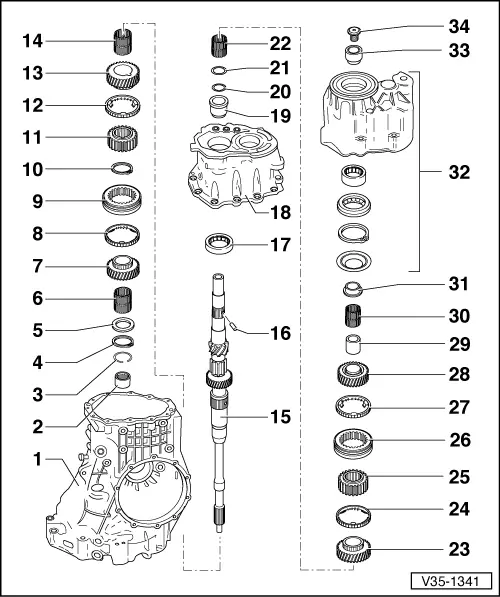

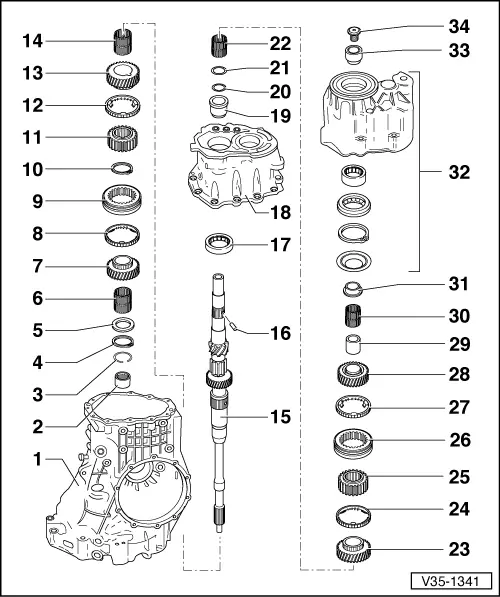

Dismantling and assembling input shaft

Dismantling and assembling input shaft

|

|

|

|

Notes:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

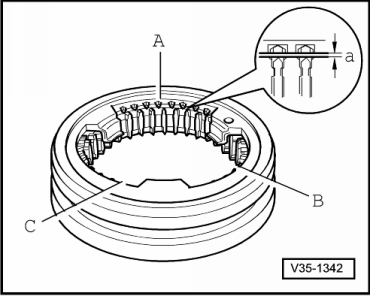

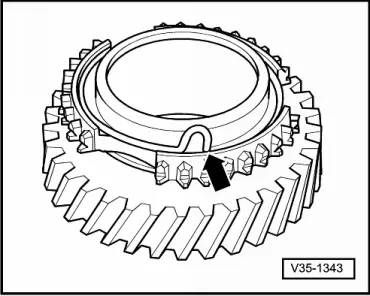

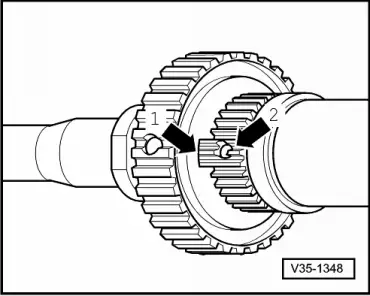

→ Fig.1 Inserting spring in sliding gear

|

|

||||||||||

|

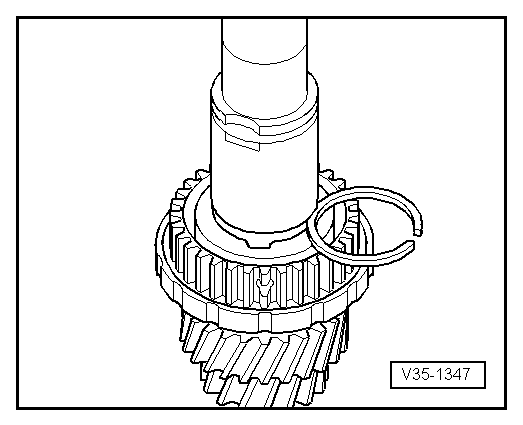

→ Fig.3 Re-determining thickness of circlip

Note: Note correct installation position when pressing on =>Fig.5.

Note: The opening of the circlip must align with the groove in the synchro-hub.

=> Parts catalogue Circlips available

| ||||||||||

|

|

|

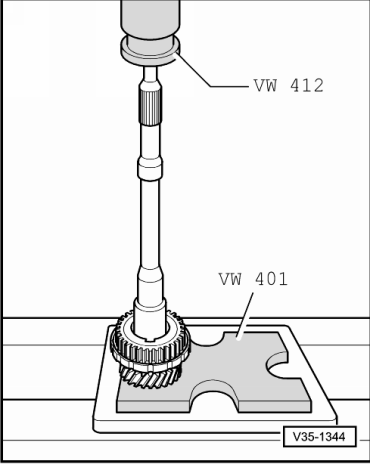

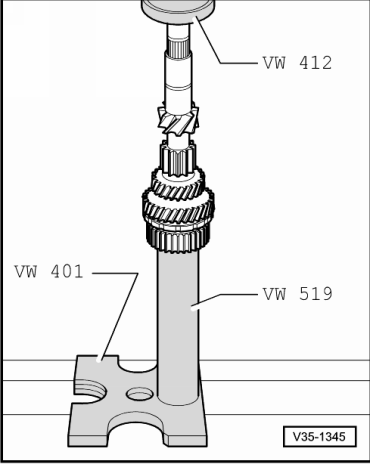

→ Fig.4 Pressing off synchro-hub for 3rd and 4th gear |

|

|

|

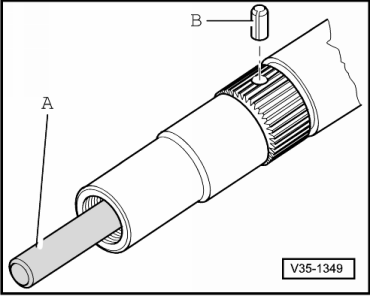

→ Fig.5 Synchro-hub installation position

|

|

|

|

→ Fig.6 Pressing on synchro-hub for 3rd and 4th gear

|

|

|

|

→ Fig.7 Driving spring pin into input shaft

|