A4 Mk1

|

Removing and installing rear final drive

Removing and installing rear final drive

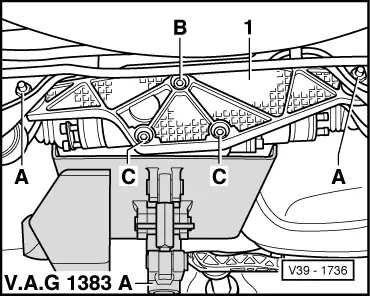

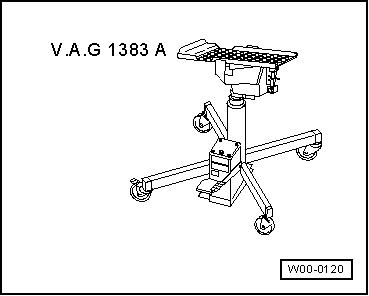

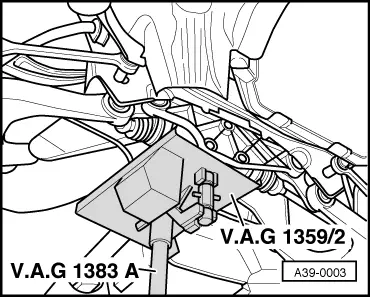

Special tools, testers and other items required |

|

|

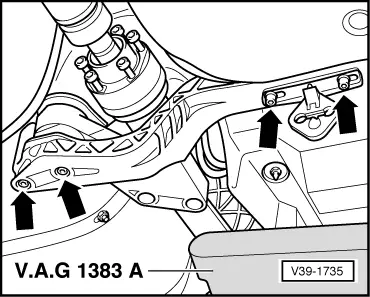

Removing

=> Engine, Mechanics; Repair Group 26; Removing and installing exhaust system components

|

|

|

|

|

|

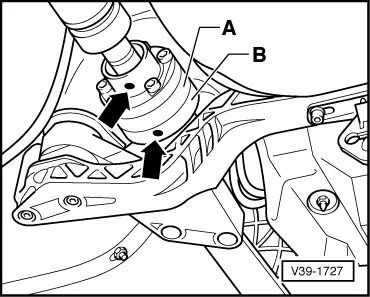

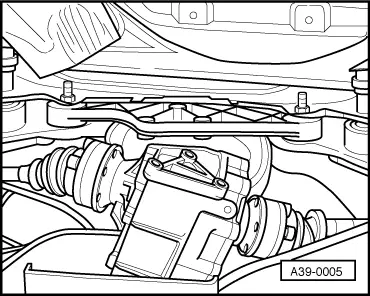

Note: If propshaft cannot be pressed upwards past flange, lower final drive and then tie up propshaft. When lowering, secure propshaft to stop it falling and pay attention to permissible propshaft bending angle => Notes, Page 39-84.

|

|

|

|

|

|

|

|

|

Notes: |

|

||||||||||||||||||||||||

=> Engine, Mechanics; Repair Group 26; Removing and installing exhaust system components Tightening torques

| ||||||||||||||||||||||||