A4 Mk1

|

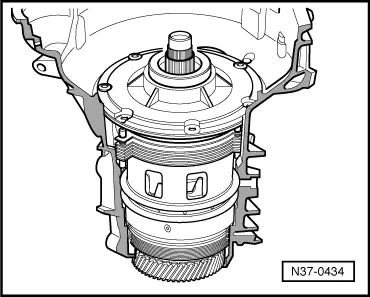

Dismantling and assembling planetary gearbox

Assembling planetary gearbox

|

|

|

|

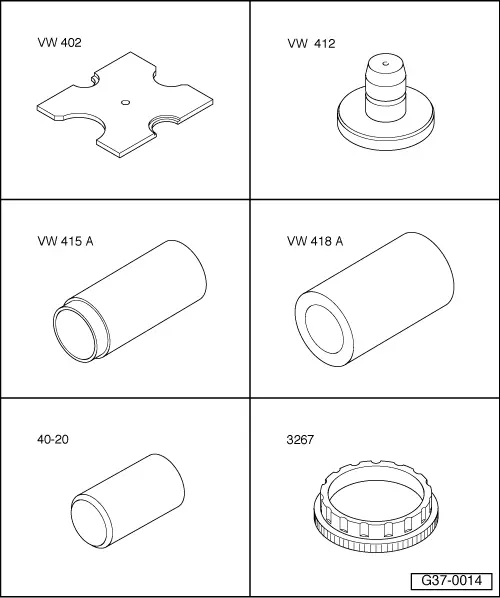

Special tools and workshop equipment required

|

|

|

|

|

|

|

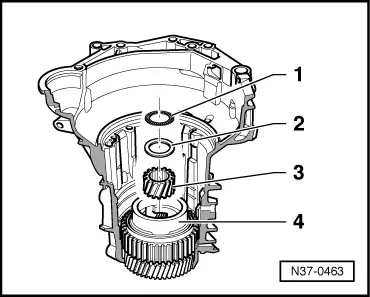

Gearboxes with code letters DMU, DMV, DMX, EPT, EPU, EPV:

|

|

|

|

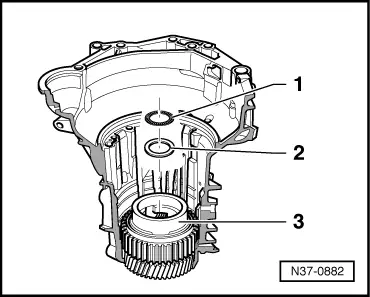

Gearboxes with other code letters:

All models

Note: Thickness of pressure plate varies according to number of plates The replacement pressure plate is assigned to the gearbox code letters. |

|

|

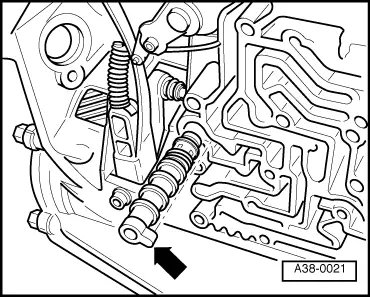

Note: When replacing the following components, adjust the reverse gear brake -B1- => Page 37-141:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Notes:

|

|

|

|

|

|

|

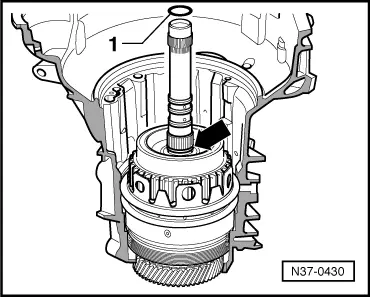

Note: On some gearboxes the clutches -K1- and -K3- must be pressed together before installing.

|

|

|

|

|

|

|

|

|

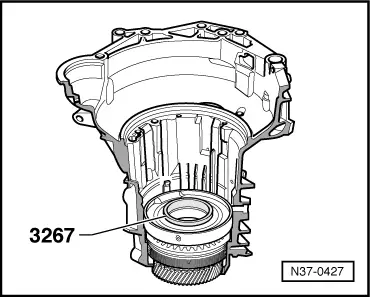

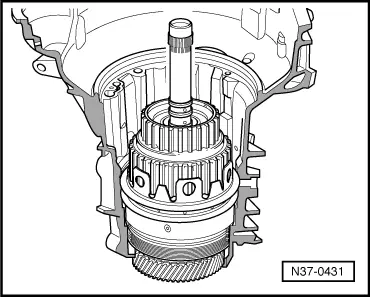

Note: When installing, rotate 3rd and 4th gear clutch -K3- until all the plates have meshed.

|

|

|

Note: If clutches -K1- and K3- are pressed together, they can only be installed as one unit. |

|

|

Notes:

|

|

|

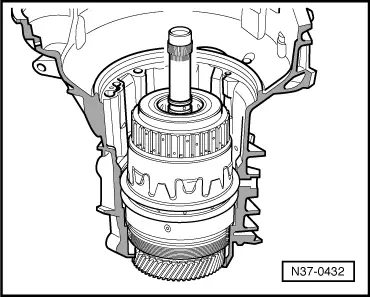

Note: When installing, rotate reverse gear clutch -K2- until all the plates have meshed.

Note: When replacing the following components, adjust the 2nd and 4th gear brake -B2- :

These components are allocated as replacement parts according to gearbox code letters. |

|

|

|

|

|

|

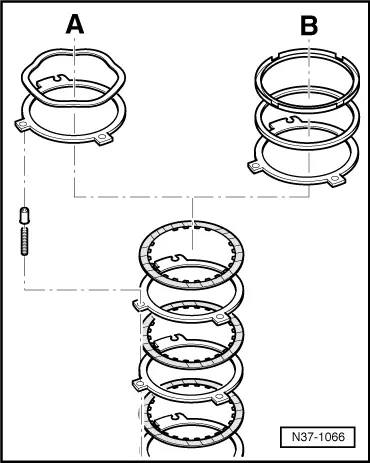

There are two versions of brake -B2-:

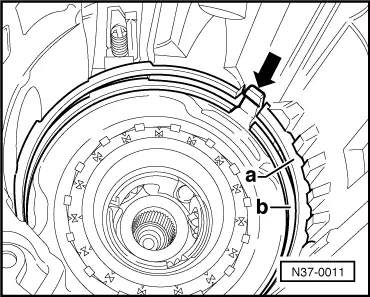

Gearboxes with a corrugated spring washer installed on the last outer plate of brake -B2- (code letters => from Page 00-3): Note: On these gearboxes the play of brake -B2- is determined by the thickness of the last outer plate. Calculating thickness of last outer plate. Note: If it is necessary to fit two outer plates because of the results of the measurement, these should be fitted together on the spring caps.

|

|

|

|

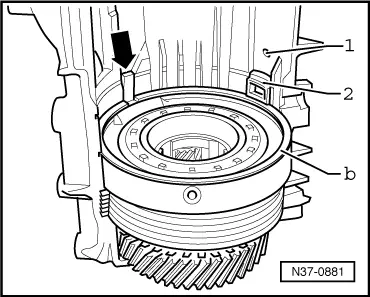

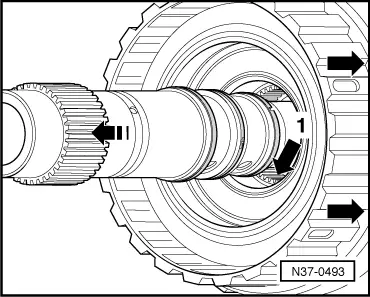

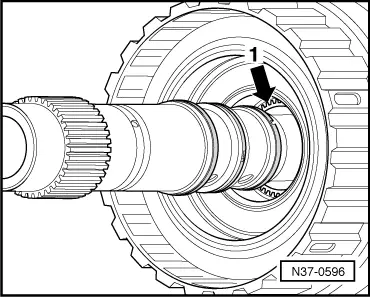

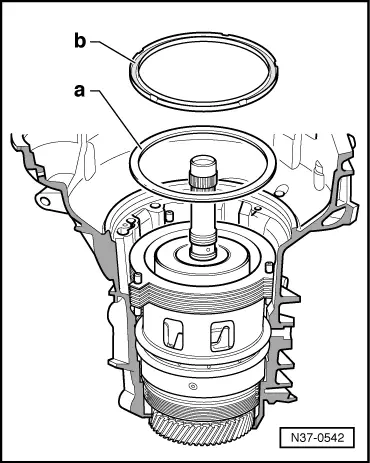

Gearboxes with a shim and a retaining ring installed in brake -B2- (code numbers => from Page 00-3): Note: → On these gearboxes, the thickness of the last outer plate is always 3 mm. The play of brake -B2- is determined by shim -a- onto which retaining ring -b- is inserted.

|

|

|

|

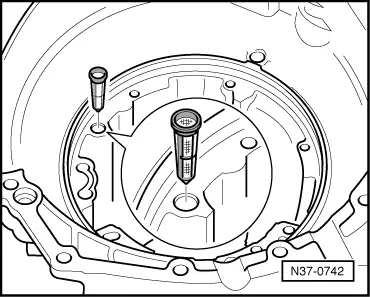

All models

Note: The strainer is located in the return pipe of the ATF cooler. It cannot be retrofitted on earlier gearbox versions. |

|

|

|

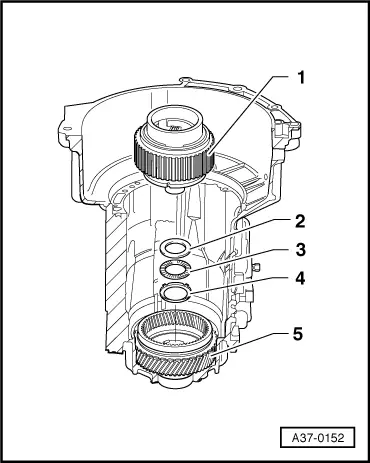

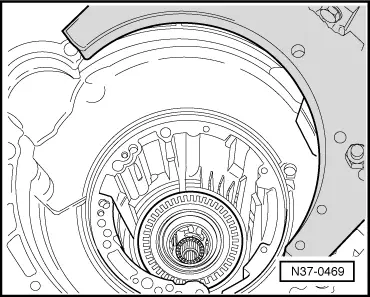

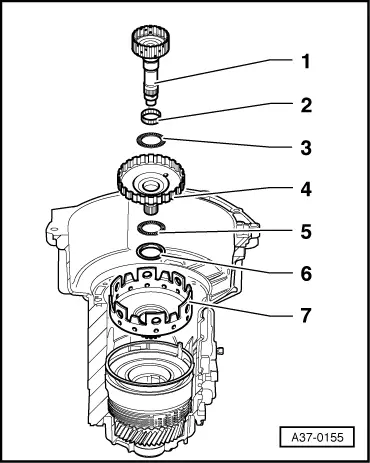

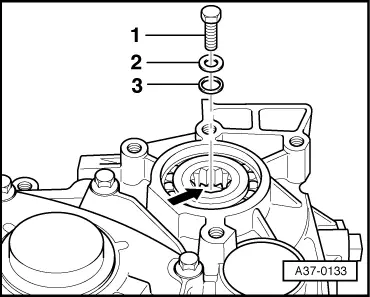

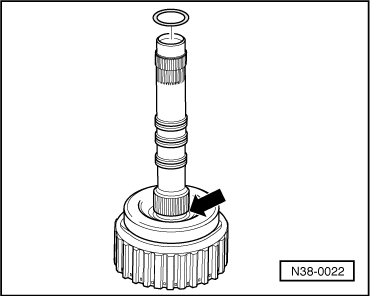

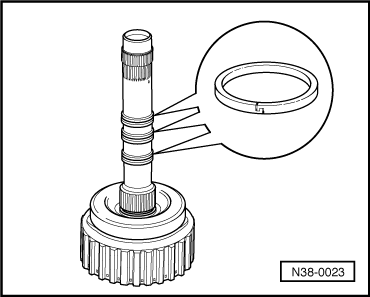

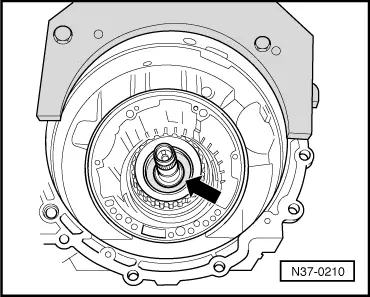

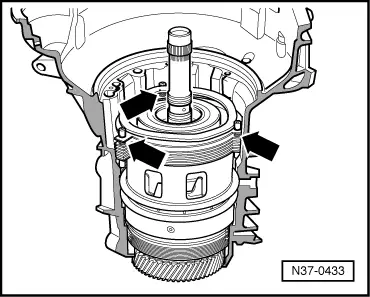

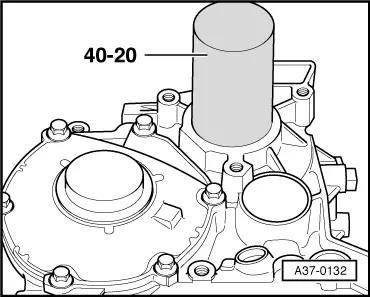

Note: Ensure the piston rings are properly seated.

Note: Ensure that the O-ring is not damaged.

|

|

|

|

|

|

|