A4 Mk1

|

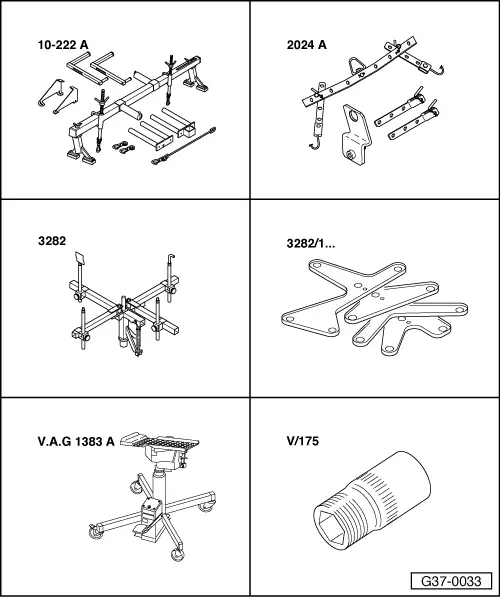

Removing and installing gearbox

Removing and installing gearbox

|

|

|

|

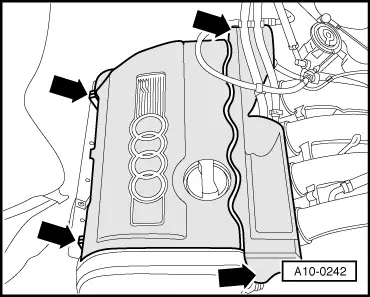

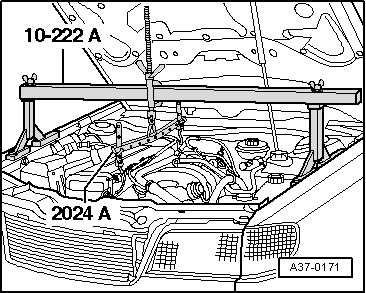

Vehicles with 1.8 ltr. petrol engine:

|

|

|

|

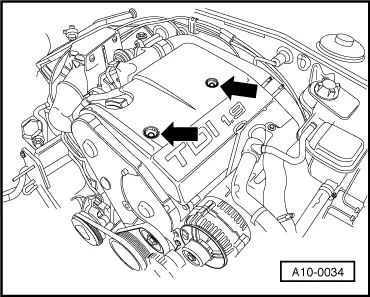

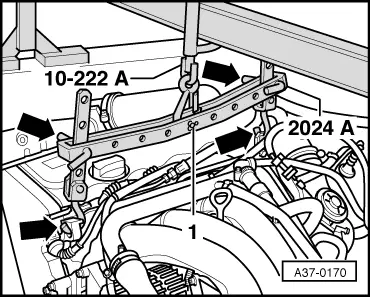

Vehicles with TDI engine:

|

|

|

|

|

|

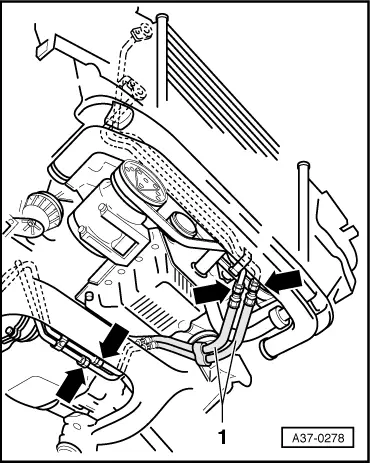

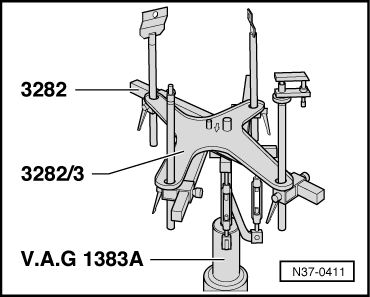

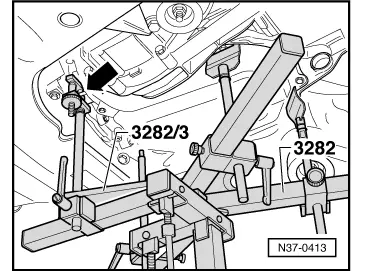

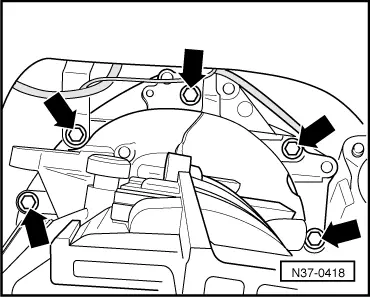

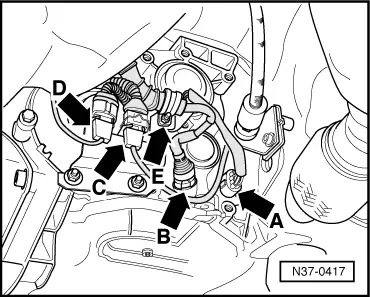

Warning

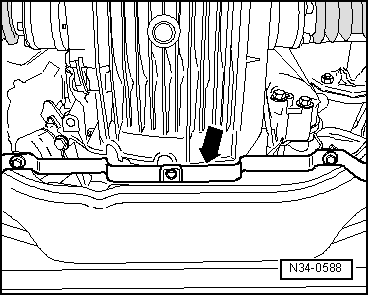

The hook attachments and locating pins on the lifting tackle must be secured with locking pins (arrows in illustration).

|

|

|

Vehicles with petrol engine:

Vehicles with TDI engine:

|

|

|

|

|

|

|

All models

|

|

|

|

|

|

|

|

|

=> Running gear, Front and four-wheel drive; Repair group 40; Removing and installing drive shaft

Notes:

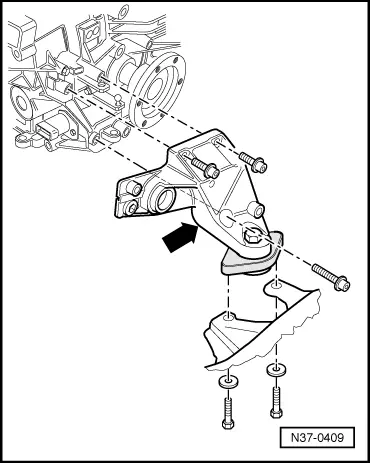

Vehicles with petrol engine and without air conditioner

|

|

|

|

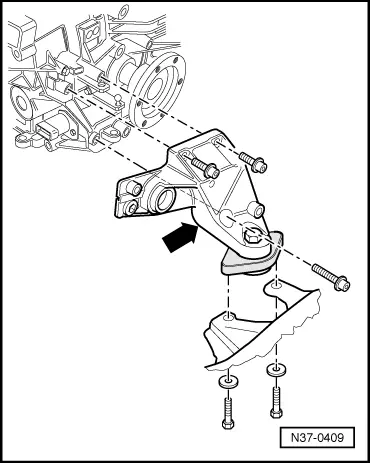

Vehicles with petrol engine and air conditioner and vehicles with TDI engine:

|

|

|

|

All models

|

|

|

|

|

|

|

|

|

|

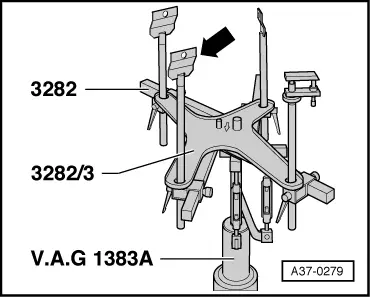

Vehicles with petrol engine and without air conditioner

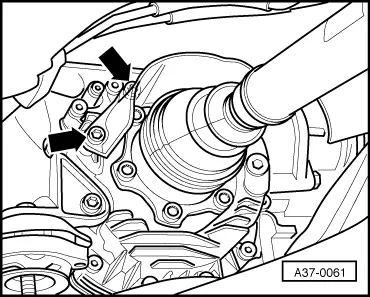

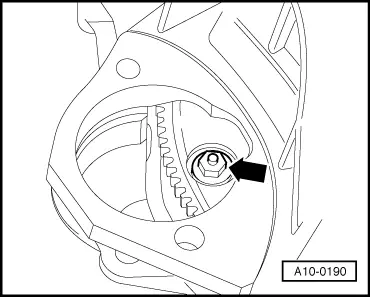

The gearbox mount 3282 is set up with the adjusting plate 3282/2 for removing the automatic gearbox 01N. The symbols on the adjusting plate indicate the mounts required, the arrow points forward. |

|

|

|

|

|

|

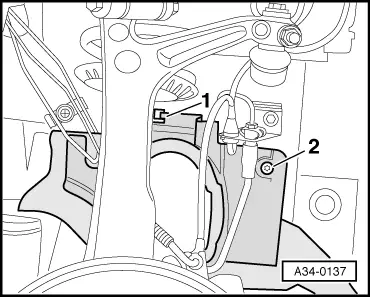

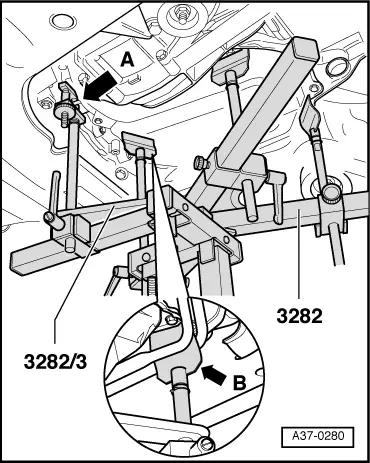

Vehicles with petrol engine and air conditioner and vehicles with TDI engine

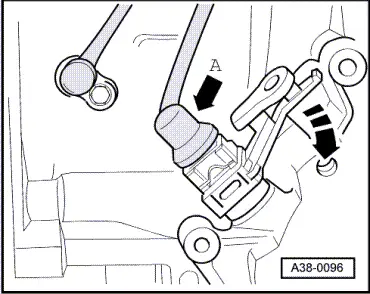

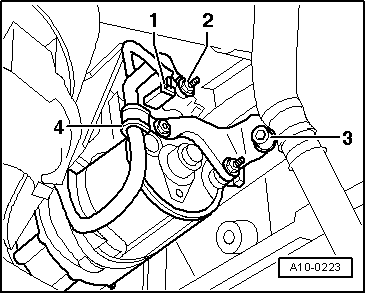

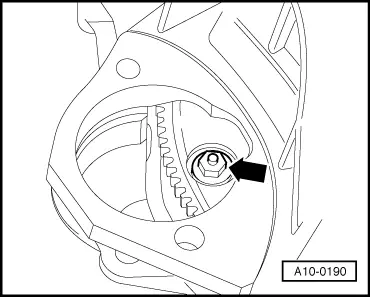

Attach a retainer plate -arrow- in place of the retainer pin (the set-up is not as indicated by the symbols on the adjustment plate). |

|

|

|

|

|

|

All models

|

|

|

Installing Install in reverse sequence; note the following points: Notes:

|

|

|

Notes:

|

|

|||||||||||||||||||

|

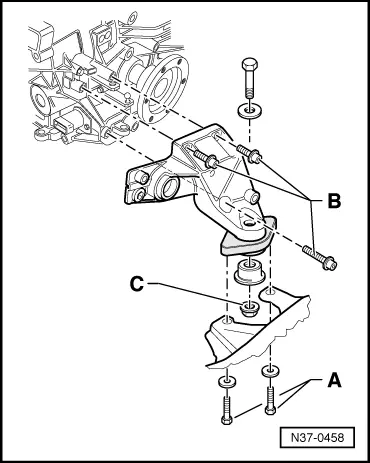

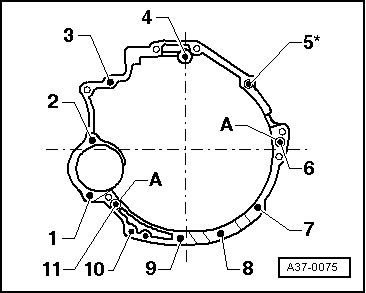

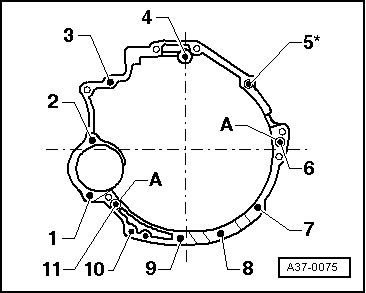

1.6 ltr. engine: → Engine/gearbox mountings

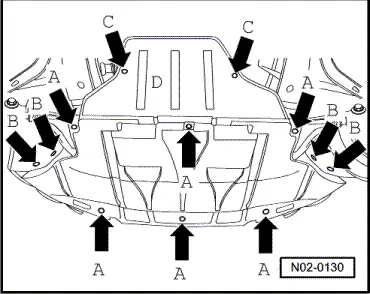

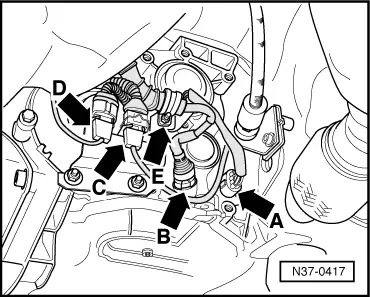

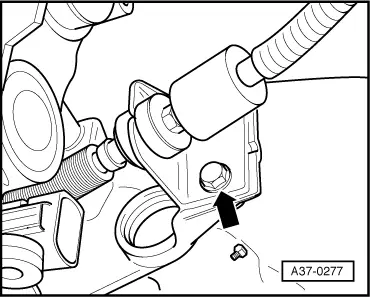

A: centering sleeves |

|

|||||||||||||

|

1.8 ltr. petrol engine, 1.9 ltr. TDI engine: → Engine/gearbox mountings

A: centering sleeves |

|

|

|

All models

=> Parts catalogue

|

|

|

=> Electrical system; Repair group 27; Removing and installing starter

=> Running gear, Front and four-wheel drive; Repair group 40; Removing and installing drive shaft

Notes:

|