-

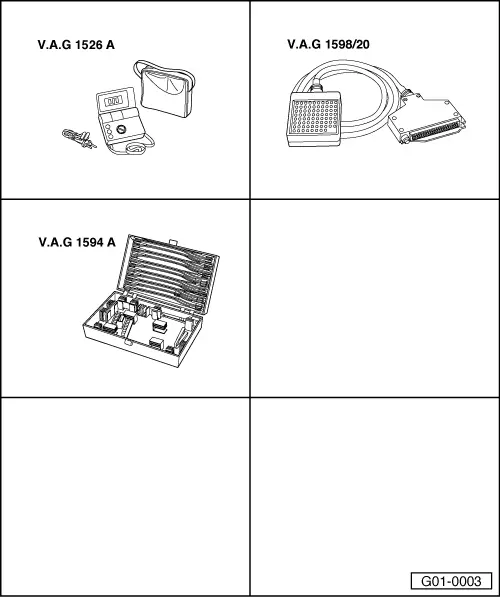

‒ → For all test steps, switch off ignition, unplug multi-pin connector from automatic gearbox control unit -J217 (control unit is located in front of right seat beneath cover in footwell => Page 01-6) and connect test box V.A.G 1598/20 to wiring harness connector.

-

‒ If readings do not match specifications, perform "Measures to be taken if reading does not match specification" as listed on right of test table.

-

‒ Perform all measures listed in column "Measures to be taken if reading does not match specification".

-

‒ Only perform test steps recommended in fault table (specific testing).

Multi-pin connector (88-pin) of automatic gearbox control unit -J217 (sockets on V.A.G 1598/20)

|

1-

|

Solenoid valve 5 -N92

|

18-

|

Kickdown switch -F8 (not with electronic throttle

and V6-TDI)

|

|

2-

|

Selector lever lock solenoid -N110

|

19-

|

Gearshift by ABS control unit

|

|

3-

|

Not used

|

20-

|

Engine intervention (ignition point adjustment) 1)

|

|

4-

|

Solenoid valve 7 -N94

|

21-

|

Gearbox oil temperature sender -G93 (ATF)

|

|

5-

|

Solenoid valve 4 -N91

|

22-

|

Gearbox oil temperature sender -G93 (ATF)

|

|

6-

|

Earth for loads (terminal 31)

|

23-

|

Gearbox input speed sender -G182 (screen)

|

|

7-

|

Not used

|

24-

|

Not used

|

|

8-

|

Multi-function switch -F125 L2

|

25-

|

Selector lever position indicator (not for highline dash panel insert)

|

|

9-

|

Multi-function switch -F125 L4; supply voltage for cruise control system

|

26-

|

Supply voltage (terminal 30), with or without fuse depending on design status => Current flow diagram

|

|

10-

|

Brake light switch -F (not with electronic throttle

and V6-TDI)

|

27-

|

Kickdown for air conditioner 1)

|

|

11-

|

Not used

|

28-

|

Earth for electronics (terminal 31) 4)

|

|

12-

|

Not used

|

29-

|

Solenoid valve 6 -N93

|

|

13-

|

Tiptronic recognition

|

30-

|

Solenoid valve 1 -N88

|

|

14-

|

Gearbox speed sender -G38

|

31-

|

Not used

|

|

15-

|

Gearbox speed sender -G38 (screen)

|

32-

|

Solenoid valve 3 -N90

|

|

16-

|

Gearbox input speed sender -G182

|

33-

|

Solenoid valve 2 -N89

|

|

17-

|

Signal for fault display (OBD II requirement) 1) 2)

|

34-

|

Earth for loads (terminal 31)

|

Notes and footnotes on assignment of multi-pin connector => Page 01-287

|

35-

|

Fuel consumption signal (engine actual torque) 1)

|

54-

|

Supply voltage (terminal 15)

|

|

36-

|

Multi-function switch -F125 L1

|

55-

|

Supply voltage (terminal 15)

|

|

37-

|

Multi-function switch -F125 L3

|

56-

|

Not used

|

|

38-

|

Not used

|

-

|

|

|

39-

|

Not used

|

-

|

|

|

40-

|

Engine speed signal 1)

|

-

|

|

|

41-

|

Throttle valve value (load signal) 1)

|

-

|

|

|

42-

|

Gearbox speed sender -G38

|

-

|

|

|

43-

|

Not used

|

-

|

|

|

44-

|

Gearbox input speed sender -G182

|

-

|

Sockets 57 - 83 not used

|

|

45-

|

Not used

|

-

|

|

|

46-

|

Tiptronic change-up

|

-

|

|

|

47-

|

Tiptronic change-down

|

-

|

|

|

48-

|

Not used

|

-

|

|

|

49-

|

Not used

|

84-

|

Not used

|

|

50-

|

Not used

|

85-

|

CAN bus 3)

|

|

51-

|

Change-up/change-down signal (for engine

intervention) 1)

|

86-

|

CAN bus 3)

|

|

52-

|

Supply voltage for solenoid valves

|

87-

|

Not used

|

|

53-

|

Supply voltage for solenoid valves

|

88-

|

Diagnosis K-wire

|

Notes and footnotes on assignment of multi-pin connector => Page 01-287

Notes and footnotes on assignment of multi-pin connector

1) Vehicles with no CAN bus only

=> Automatic Gearbox 01V Front and Four-Wheel Drive; Repair Group 00; Code letters, assignment of mechanical units, transmission ratios, features

2) Signal is transmitted via engine control unit to gearbox control unit and can only be checked in measured value block => Page 01-194.

3) Vehicles with CAN bus only. For further information on CAN bus, refer to => Page 01-271

=> Automatic Gearbox 01V Front and Four-Wheel Drive; Repair Group 00; Code letters, assignment of mechanical units, transmission ratios, features

4) Control-unit pin 28 is not used on vehicles with 10-pin connector for multi-function switch -F125.

List of test steps (88-pin connector)

|

Component checked

|

|

Component checked

|

|

|

Automatic gearbox control unit -J217 supply voltage

|

- Perform test steps 1

and 7

|

Solenoid valve 5 -N92

(pressure control valve 2 -N216)

|

- Perform test steps 13

and 8

|

|

Selector lever lock solenoid -N110

|

- Perform test steps 2, 6 and 16

|

Solenoid valve 6 -N93

(pressure control valve 3 -N217)

|

- Perform test steps 14

and 8

|

|

Brake light switch -F

|

- Perform test step 3

|

Solenoid valve 7 -N94

(pressure control valve 4 -N218)

|

- Perform test steps 15

and 8

|

|

Supply voltage for cruise control system

|

- Perform test step 4

|

Gearbox speed sender -G38(gearbox output speed sender -G195)

|

- Perform test step 18

|

|

Kickdown switch -F8

(not for V6 TDI and electronic throttle)

|

- Perform test steps 5

and 17

|

Gearbox input speed sender -G182

|

- Perform test step 19

|

|

Multi-function switch

(driving range sensor) -F125

|

- Page => 01-314

|

Gearbox oil temperature sender -G93 (ATF)

|

- Perform test step 20

|

|

Solenoid valve 1 -N88

|

- Perform test steps 8

and 9

|

Wiring to engine control unit 1)

|

- Perform test steps 21, 22, 23, 24 and 25

|

|

Solenoid valve 2 -N89

|

- Perform test steps 10 and 8

|

Tiptronic switch -F189

|

- Perform test steps 26 and 27

|

|

Solenoid valve 3 -N90

|

- Perform test steps 11

and 8

|

CAN bus 2)

|

- Test step 28 and check bus system => Page 01-273

|

|

Solenoid valve 4 -N91

(pressure control valve 1 -N215)

|

- Perform test steps 12

and 8

|

|

|

1) Signal is transmitted via engine control unit to gearbox control unit (checking for vehicles with no CAN bus only)

=> Automatic Gearbox 01V Front and Four-Wheel Drive; Repair Group 00; Code letters, assignment of mechanical units, transmission ratios, features

2) Checking for vehicles with CAN bus only

=> Automatic Gearbox 01V Front and Four-Wheel Drive; Repair Group 00; Code letters, assignment of mechanical units, transmission ratios, features

|