-

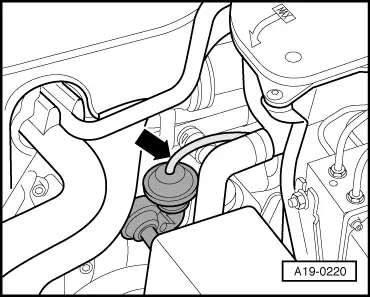

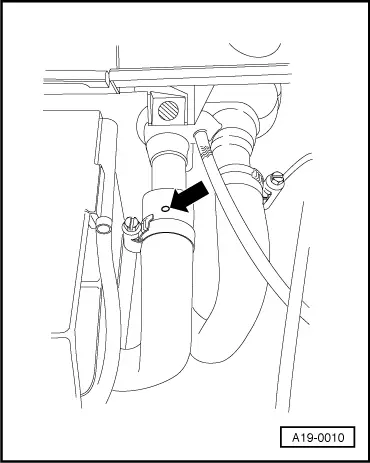

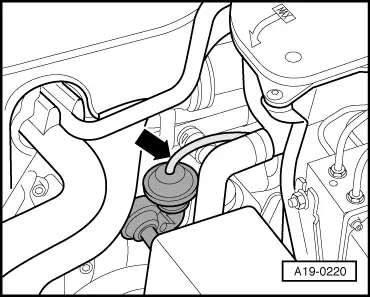

‒ → To drain off the remaining coolant, disconnect coolant hose -arrow- from oil cooler.

Filling

Notes:

-

◆ The cooling system is filled all year round with a mixture of water and radiator anti-freeze/anti-corrosion agent.

-

◆ Exclusive use is to be made as coolant additive of G 012 A8 D as per TL VW 774 D.

Identifiable by: red colour

Attention:

Use only coolant additive G

-

◆ If fluid in expansion tank is brown, G 012 A8 D has been mixed with a different type of coolant. In this case, flush out cooling system and replace coolant. To flush out, fill cooling system with clean water and allow engine to run for approx. 2 minutes. This should remove virtually all the old coolant.

-

◆ G 012 A8 D and coolant additives marked "meeting specification TL VW 774 D" prevent frost and corrosion damage, stop scale forming and at the same time raise the boiling point of the coolant. The cooling system must therefore be filled all year round with anti-freeze and anti-corrosion additive.

-

◆ On account of the higher boiling point, the coolant helps to enhance engine reliability under heavy loads particularly in countries with tropical climates.

-

◆ Frost protection must be guaranteed to around -25 °C (in countries with arctic climate to around -35 °C).

-

◆ The coolant concentration must not be reduced by adding water even in warmer seasons and in warmer countries. The anti-freeze ratio must be at least 40 %.

-

◆ If greater frost protection is required in very cold climates, the amount of G 012 A8 D can be increased, however only up to 60 % (giving frost protection to around -40 °C), otherwise frost protection decreases again and cooling efficiency is also impaired.

-

◆ Exclusive use is to be made of clean drinking water for mixing coolant.

-

◆ If the radiator, heat exchanger, cylinder head, cylinder head gasket or cylinder block has been replaced, do not re-use used coolant.

-

◆ Always replace gaskets and sealing rings.

-

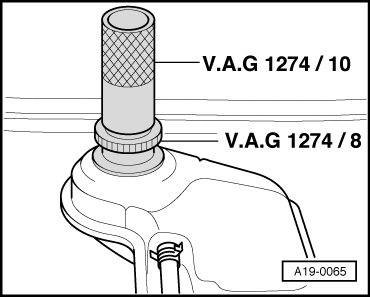

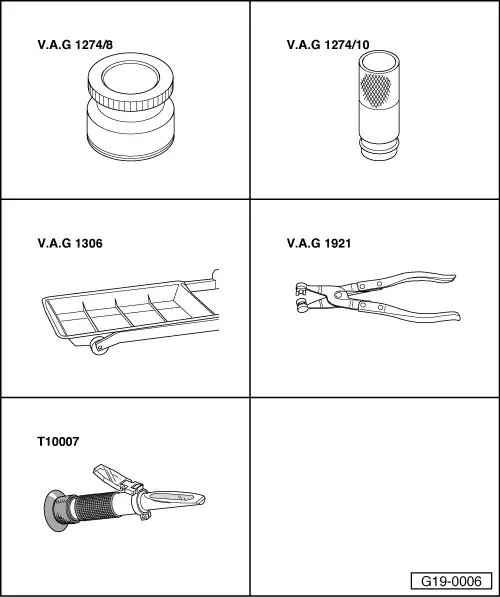

◆ For checking anti-freeze protection in cooling system, use must be made for coolant additive G012 A8 D of the special tool T10007.

Recommended mixing ratios:

|

|

|---|

|

Frost protection to

|

Anti-freeze part

|

G 012A8 D 1)

|

Water 1)

|

|

-25 °C

-35 °C

|

40 %

50 %

|

3.0 l

3.5 l

|

4.0 l

3.5 l

|

1) Coolant 7.0 litres; may vary depending on vehicle specification.

-

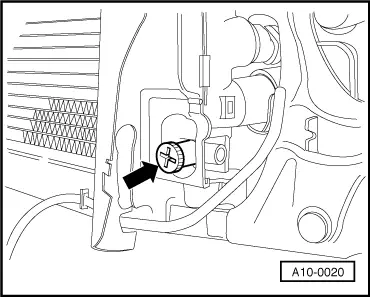

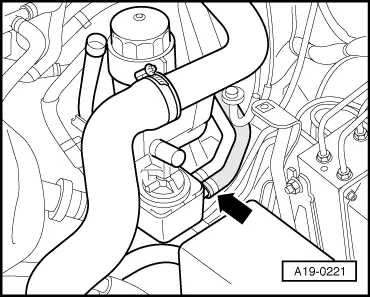

‒ Fit and secure coolant hoses.

-

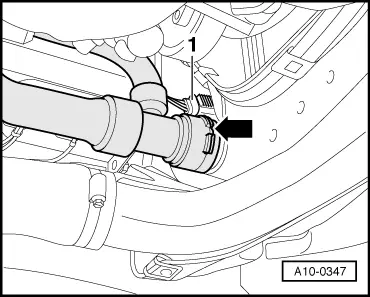

‒ Close drain plug at radiator.

|