A4 Mk1

|

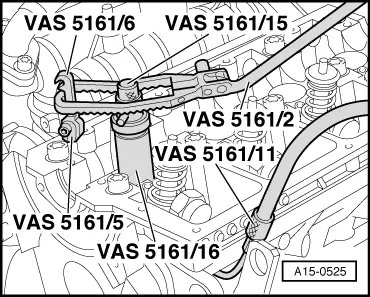

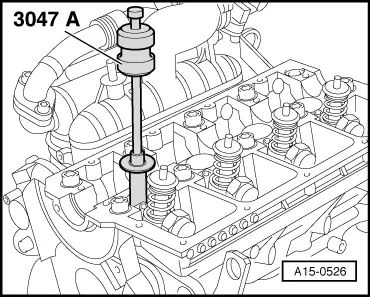

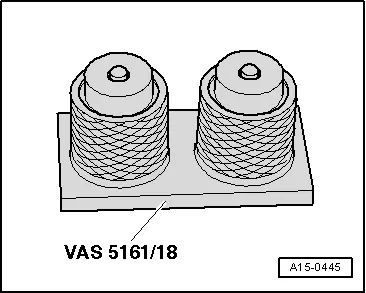

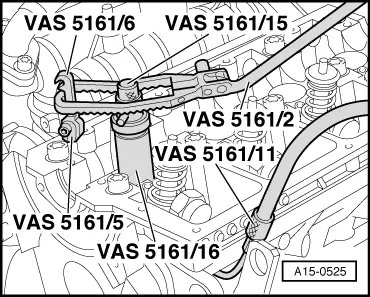

Servicing valve gear

Replacing valve stem seals

|

|

|

|

|

|

Notes:

|

|

|

|

|

|

|

|

|

|

|

|

|

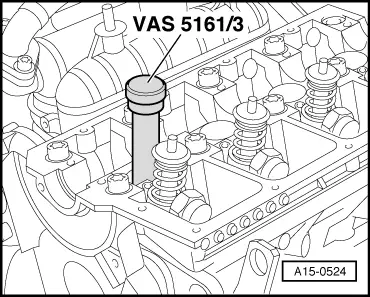

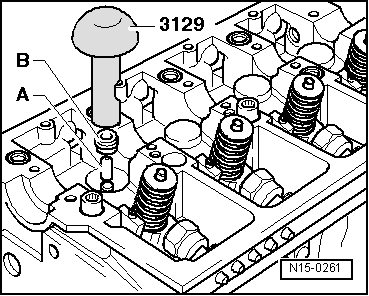

Installing Note: A plastic sleeve -A- is included with the new valve stem seals.

|

|

|

Note: Large valve key diameter faces upwards.

|

|

||||||||||||||||

Notes:

Tightening torques

| ||||||||||||||||