A4 Mk1

|

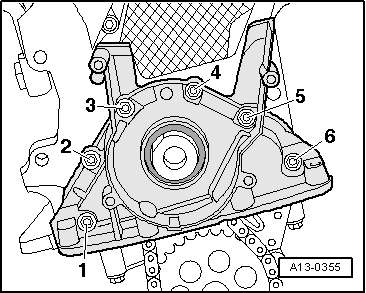

Removing and installing sealing flanges and flywheel / drive plate

Removing and installing front sealing flange

|

|

|

|

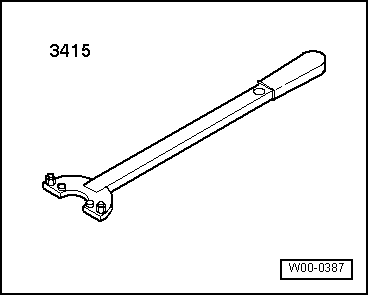

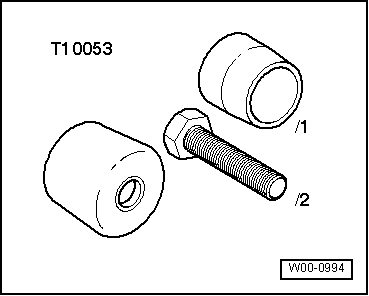

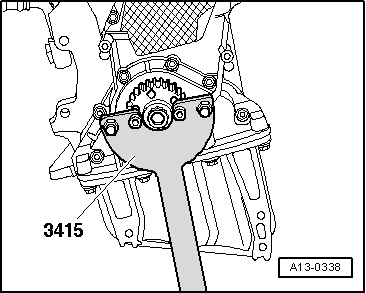

Special tools and workshop equipment required

|

|

|

Notes:

Removing

Vehicles with air conditioner:

|

|

|

|

All models:

|

|

|

|

|

|

|

|

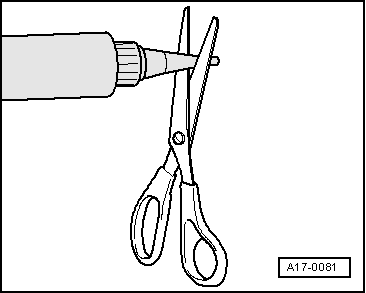

Attention:

Use safety goggles.

|

|

|

|

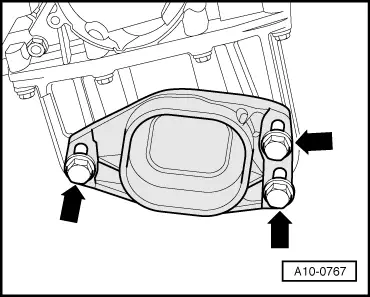

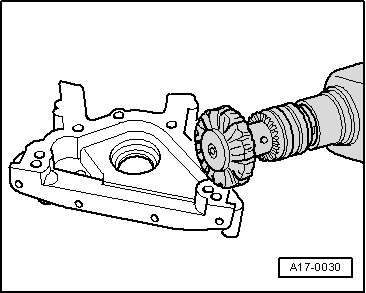

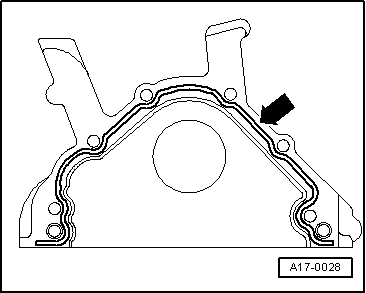

Installing Note: Sealing flange must be fitted within 5 minutes after applying silicone sealant.

|

|

|||||||

Note: Sealant bead must not be thicker than 3 mm, as otherwise excess sealant could ingress into sump and clog strainer in oil intake pipe.

Note: Use guide sleeve T10053/1 to fit sealing flange with oil seal already fitted.

Note: After installing, wait for approx. 30 minutes for sealant to dry before pouring in engine oil.

Tightening torque

|