A4 Mk1

|

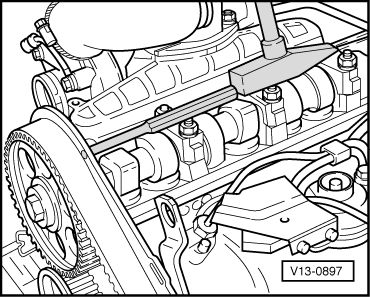

Servicing valve gear

Removing and installing camshaft

|

|

|

|

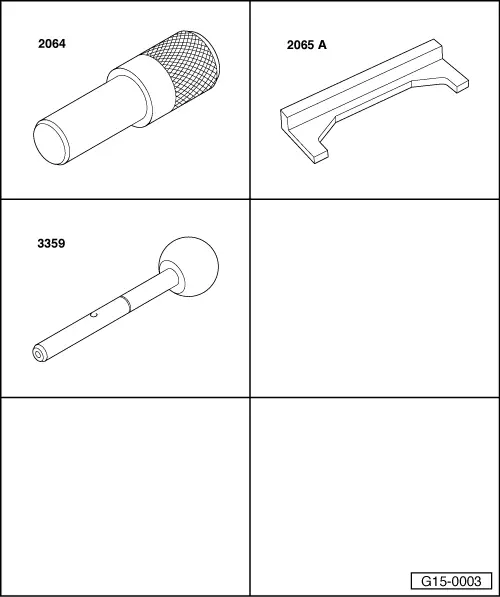

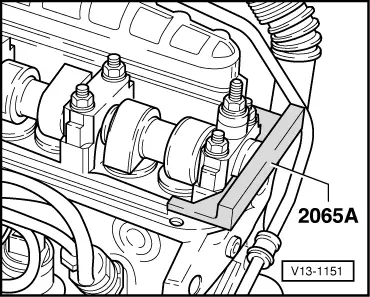

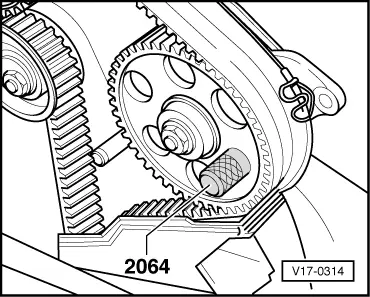

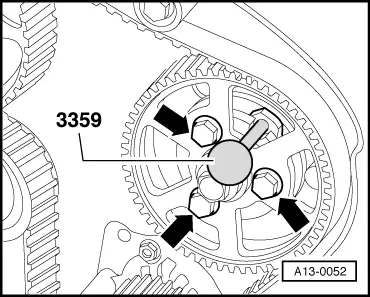

Special tools,

Removing |

|

|

|

|

|

|

|

|

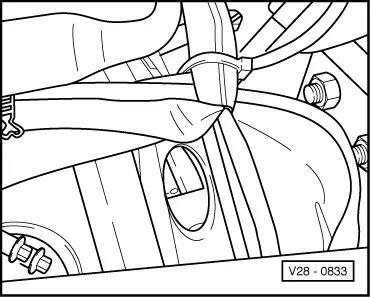

Vehicles with engine codes 1Z, AFF, AFN, AHU: |

|

|

Vehicles with engine code AHH: |

|

|

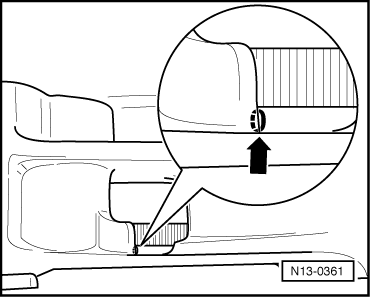

Note: |

|

|

|

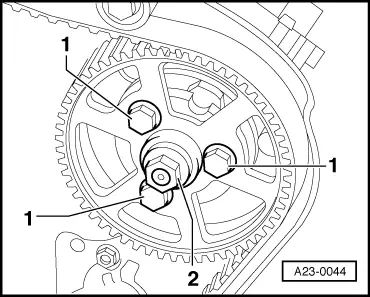

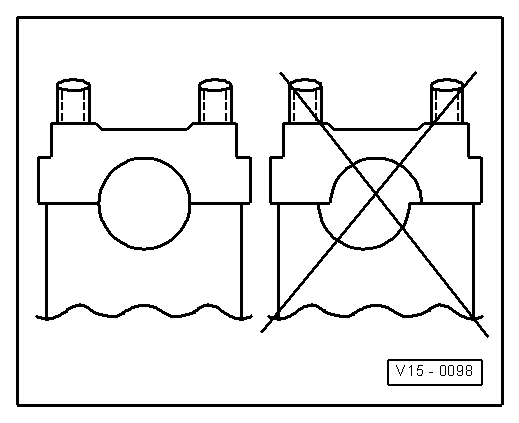

→ Do not loosen central nut -2- of injection pump sprocket. Otherwise the injection pump basic setting is maladjusted and can no longer be corrected using workshop tools. All models:

Note: |

|

|||||||

Notes:

Tightening torque

|