-

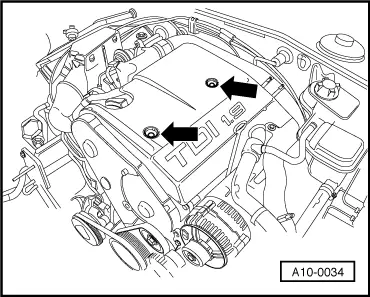

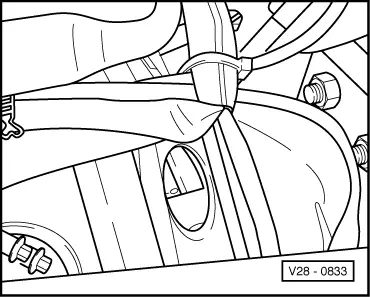

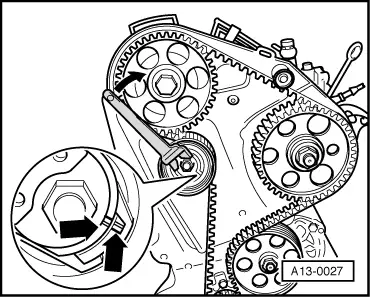

‒ → Turn tensioner eccentric clockwise using nut driver (e.g. Matra V/159) until notch and lobe -arrows- are aligned.

Note:

If eccentric has been turned too far clockwise during tensioning, tensioner must then be fully released. Then turn eccentric clockwise again to tension.

-

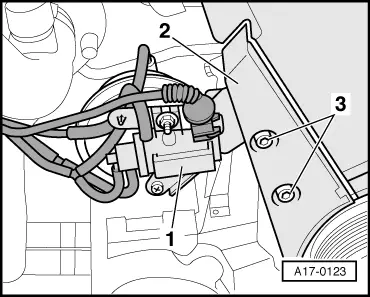

‒ Tighten lock nut on tensioner to 20 Nm.

-

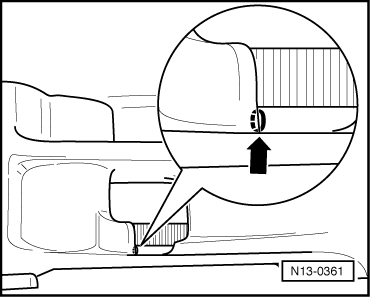

‒ Check again whether TDC mark on flywheel and reference mark are aligned.

-

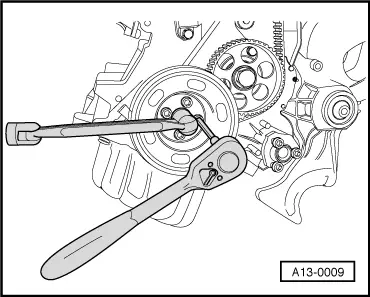

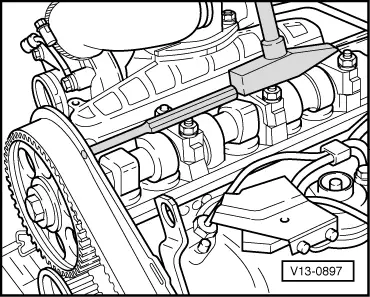

‒ Tighten securing bolt for camshaft sprocket to 45 Nm.

Note:

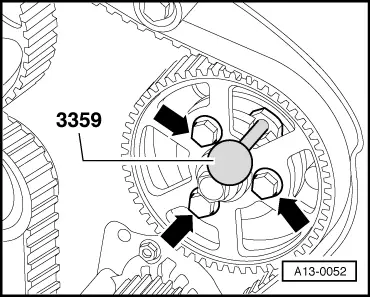

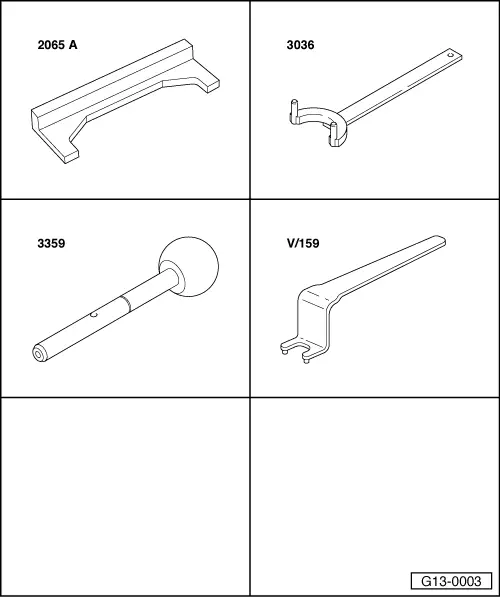

Never use setting bar to counterhold when loosening and tightening camshaft sprocket. Counterhold with 3036.

-

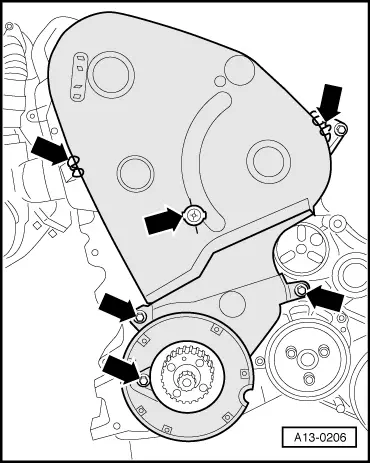

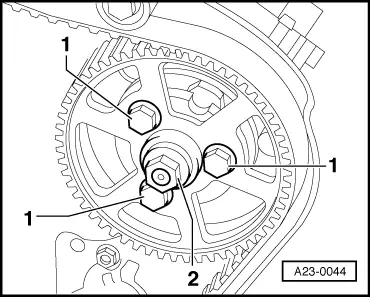

‒ Tighten new securing bolts for injection pump sprocket initially to 20 Nm.

Notes:

-

◆ After injection start dynamic test, bolts must be tightened by a 1/4 (90°) turn.

-

◆ The securing bolts are stretch bolts and cannot be re-used. Once tightened to correct torque (20 Nm + 90°), they must be replaced after loosening.

-

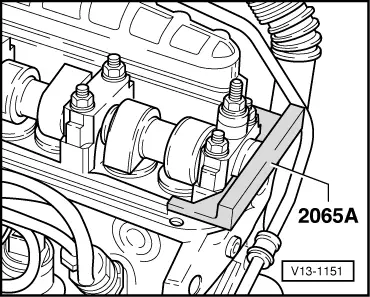

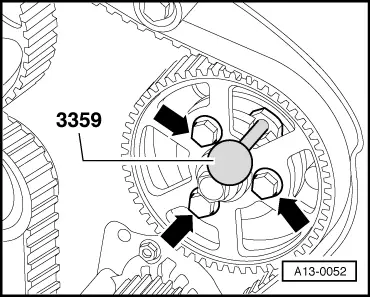

‒ Remove setting bar 2065 A from camshaft and setting pin 3359 from injection pump sprocket.

-

‒ Turn crankshaft a further two rotations in direction of engine rotation and reset to TDC No. 1 cylinder.

|