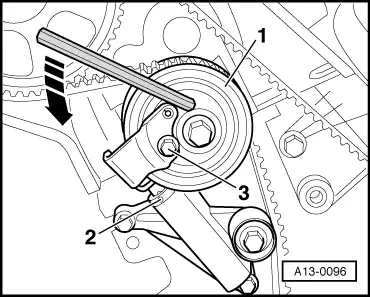

| Vehicles from 06.1999 onwards: |

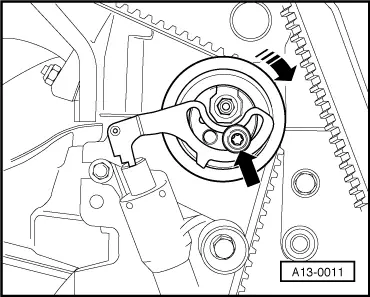

Caution | Risk of damage to toothed belt tensioner. |

| The toothed belt tensioner is oil-damped and can therefore only be compressed slowly by applying constant pressure. |

|

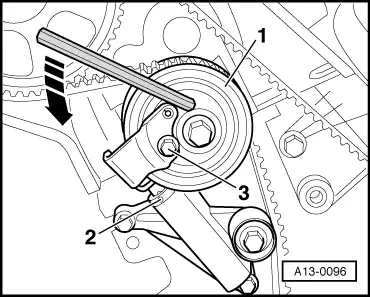

| –

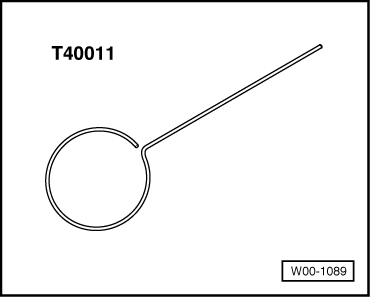

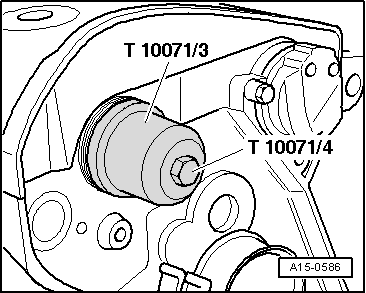

| Applying constant and moderate force, apply hexagon key through opening -2- to press toothed belt tensioning roller -1- anti-clockwise -arrow- until piston can be locked with locking pin -T40011-. |

| –

| Insert locking pin -T40011- and make sure that it remains in place. |

Note | Bolt -3- must not be slackened. |

| –

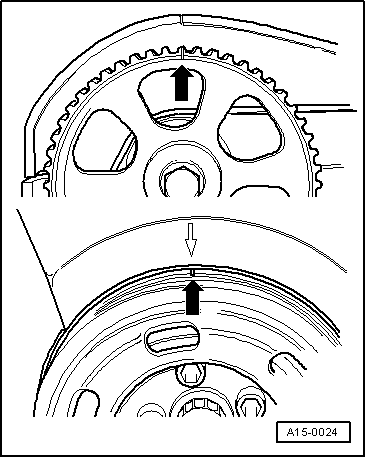

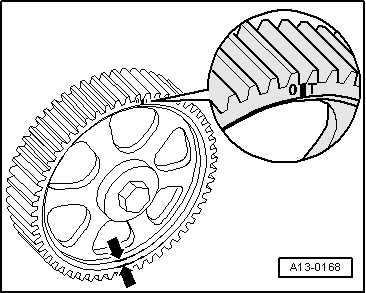

| Remove toothed belt from camshaft sprocket. |

|

|

|

Note

Note

Note

Note

Caution

Caution