A4 Mk1

|

Removing and installing parts of fuel supply system

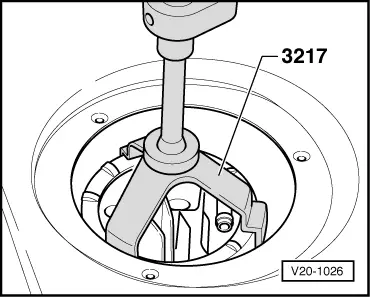

Removing and installing fuel delivery unit

Observe notes . Observe safety precautions=> Page 20-2 Observe rules for cleanliness => Page 20-3 Special tools, testers and auxiliary items

Removing Notes:

|

|

|

|

|

|

|

|

|

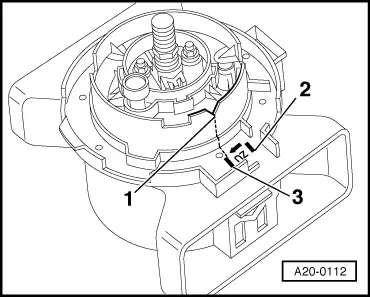

Pre-assembling flange and inner section of baffle housing

|

|

|

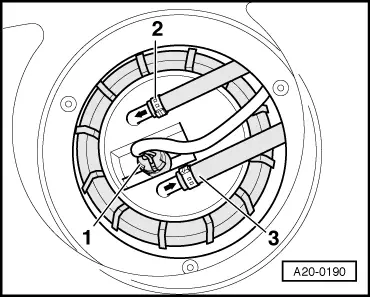

Note: Fit a toothed washer under each nut.

|

|

|

|

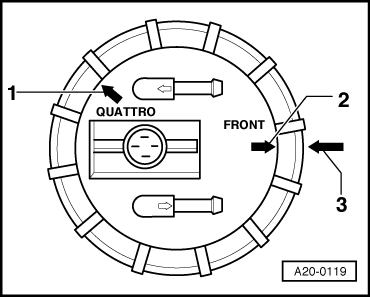

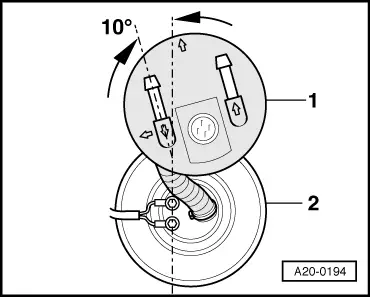

Baffle housing is shown without fuel tank for a clearer illustration.

|

|

|||||||

Note: The pipe retainer -Item 20-16 must be held in position when tightening the union nut.

Note: Ensure that fuel pipes are fitted securely.

Tightening torque

| |||||||