| –

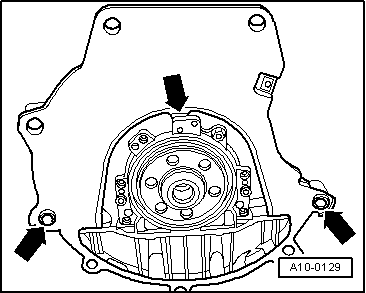

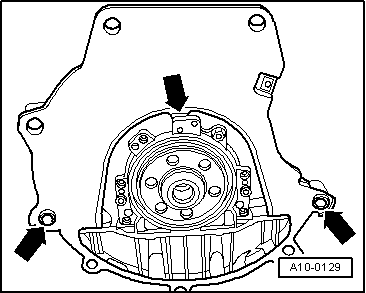

| Ensure that the intermediate plate is engaged on the sealing flange and pushed onto the dowel sleeves -arrows-. |

| –

| Attach engine to gearbox and screw in one bolt finger-tight. |

| –

| Install engine mounting (left-side). |

| –

| Release spindle of support bracket -10-222 A-. |

| –

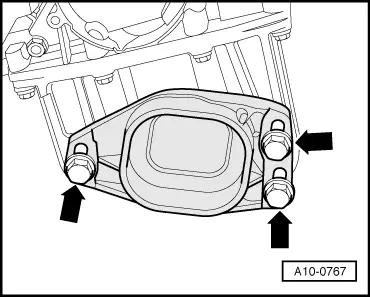

| Lower engine, inserting studs of engine mountings into consoles for engine mountings as you do so. |

Note | t

| Tightening torques apply only to lightly greased, oiled, phosphated or black-finished nuts and bolts. |

| t

| Additional lubricant such as engine oil or gearbox oil may be used, but do not use lubricant containing graphite. |

| t

| Do not use degreased parts. |

| t

| Tolerance for tightening torques ± 15 %. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note

Caution

Caution