A4 Mk1

| Renewing crankshaft oil seal (pulley end) |

| Special tools and workshop equipment required |

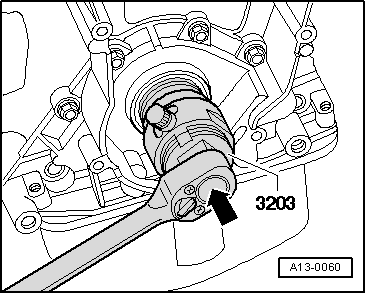

| t | Oil seal extractor -3203- |

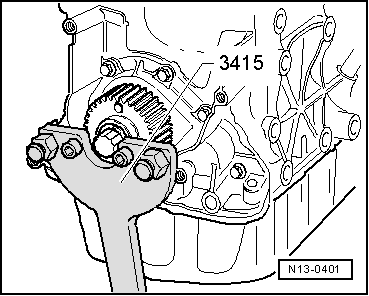

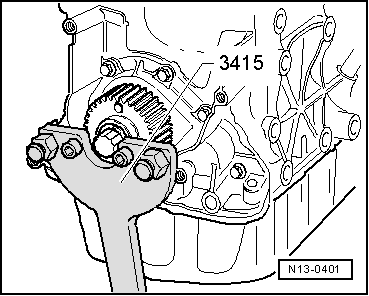

| t | Counterhold tool -3415- |

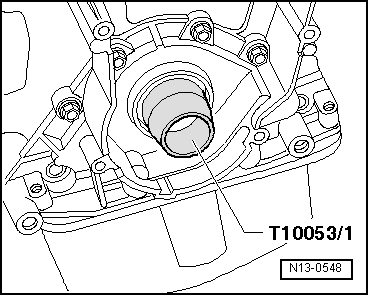

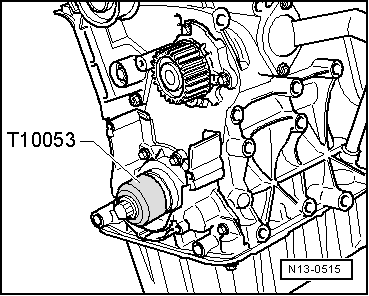

| t | Assembly tool -T10053- |

Note

Note

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

| Component | Nm | ||||

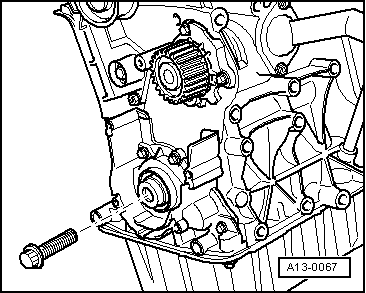

| Toothed belt sprocket to crankshaft | 90 + 90° 1)2) | ||||

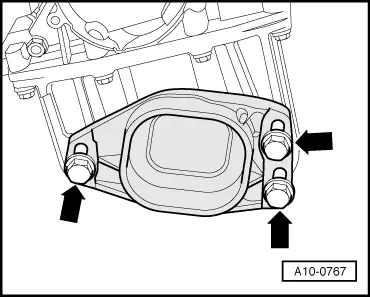

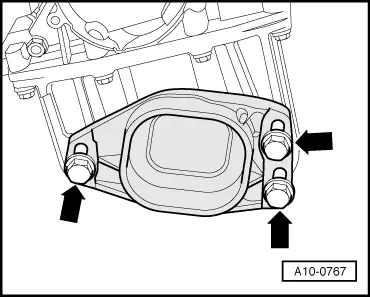

| Stop for torque reaction support to sump | 28 | ||||

| |||||