A4 Mk1

|

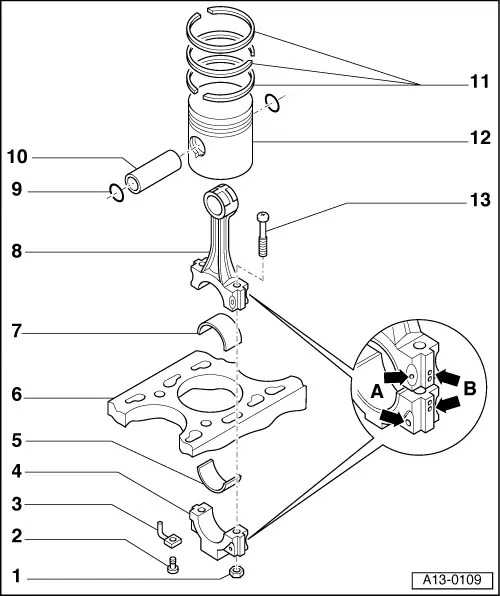

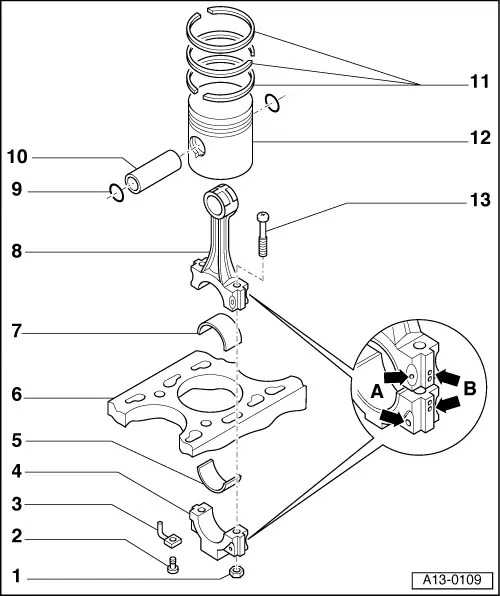

Dismantling and assembling pistons and conrods

Dismantling and assembling pistons and conrods

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

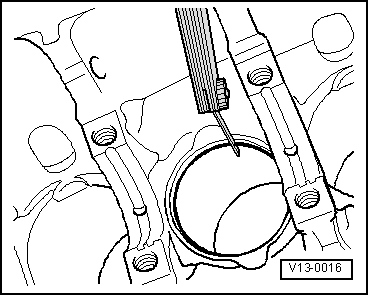

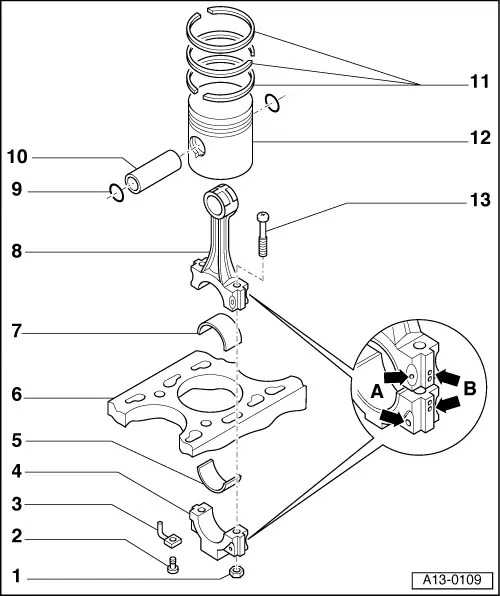

→ Fig. 2 Checking ring to groove clearance

|

|

|

|

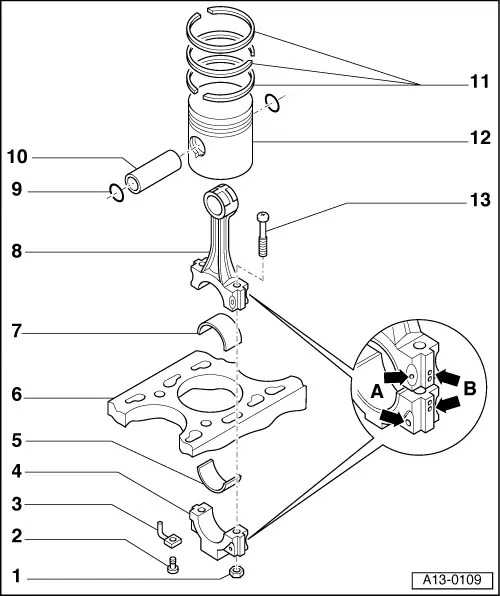

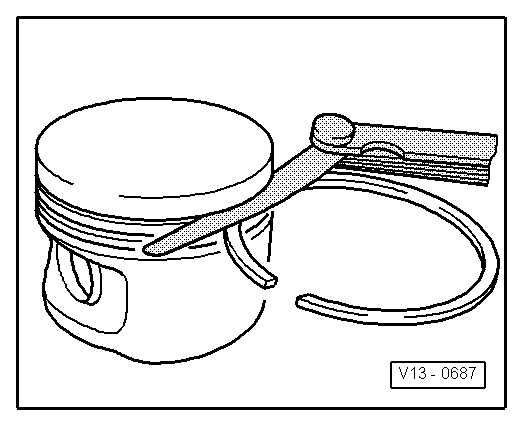

→ Fig. 3 Checking piston

|

|

|

|

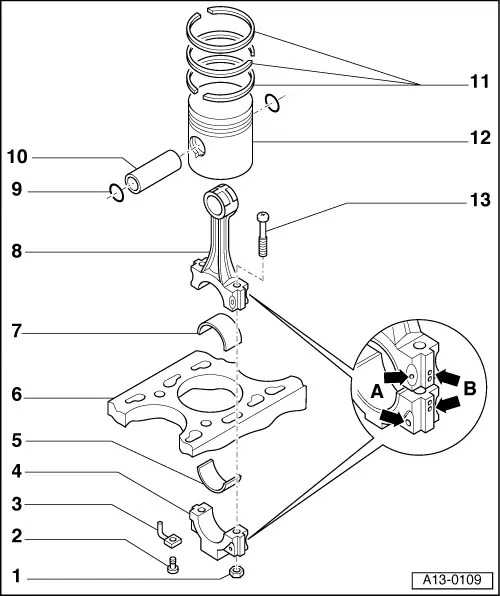

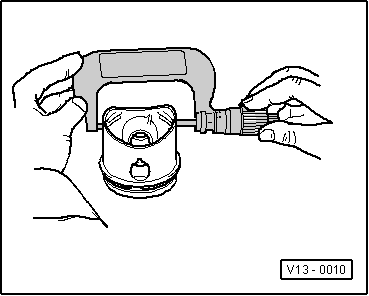

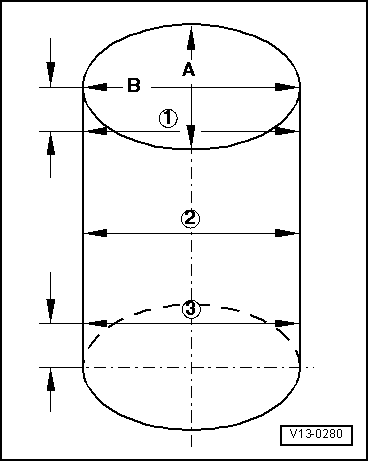

→ Fig. 4 Checking cylinder bores

|