A4 Mk1

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

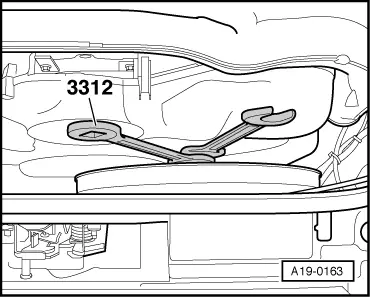

| Tightening torque for viscous fan | Nm |

| Torque wrench -V.A.G 1331- together with open-end spanner -3312- | 37 |

| Torque wrench -V.A.G 1331- without open-end spanner -3312- | 70 |

|

Note

Note

Note

Note

Note

Note

|

|

|

|

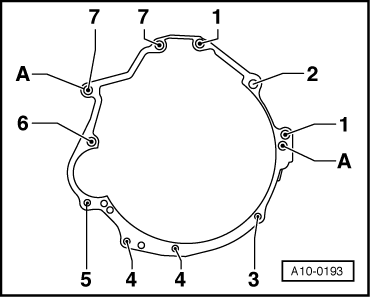

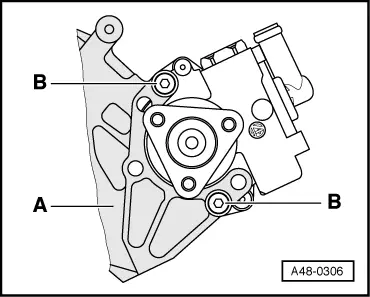

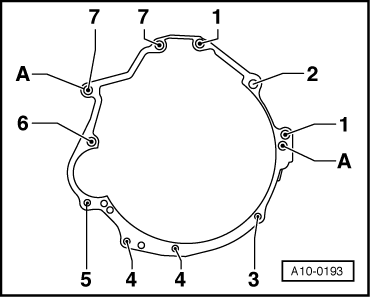

| Item | Bolt | Nm | ||

| 1 | M12x80 | 65 | ||

| 2 | M12x90 | 65 | ||

| 3 | M10x50 1) | 45 | ||

| 4 | M10x45 | 45 | ||

| 5 | M10x135 | 65 | ||

| 6 | M12x110 | 65 | ||

| 7 | M12x67 | 65 | ||

| A | Dowel sleeves for centralising | |||

| ||||

|

|

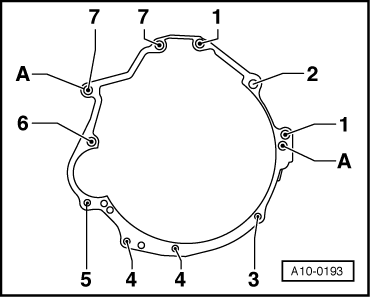

| Item | Bolt | Nm |

| 1 | M12x80 | 65 |

| 2 | M12x90 | 65 |

| 3 | M10x60 | 45 |

| 4 | M10x45 | 45 |

| 5 | M10x80 | 65 |

| 6 | M12x110 | 65 |

| 7 | M12x67 | 65 |

| A | Dowel sleeves for centralising | |

| Component | Nm | |

| Bolts/nuts | M6 | 10 |

| M8 | 20 | |

| M10 | 45 | |

| M12 | 65 | |

| Except for the following: | ||

| Engine support to cylinder block | 45 | |

| Air cleaner housing to body | 10 | |

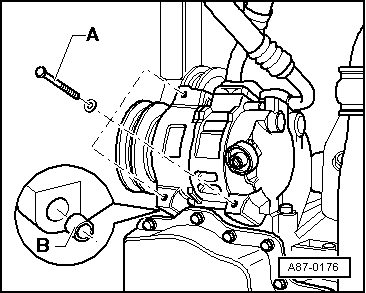

| Tensioning roller for poly V-belt for A/C compressor to bracket | 22 | |

| Front exhaust pipe to connection for turbocharger | 25 | |

| Heat shield to turbocharger | 10 | |

| Support for intermediate flange to intermediate flange | 22 | |

| Drain plug to coolant drain pipe | 10 | |

| Stop for torque reaction support to lock carrier | 25 | |

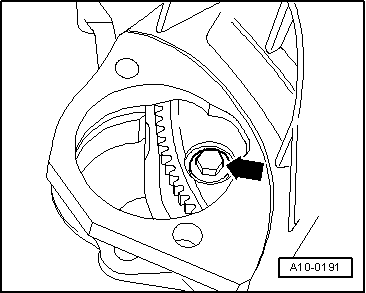

| Drive plate to torque converter M10x1 | 85 | |

| Air conditioner compressor to bracket | 22 | |

| Power steering pump to bracket for power steering pump and oil cooler | 22 | |

| Underbody cross member to body | 20 | |

| Poly V-belt pulley to power steering pump | 22 | |

| Engine mounting to subframe | 25 | |

Caution

Caution