| t

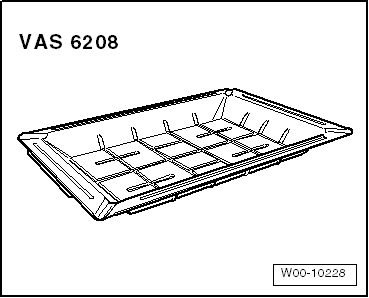

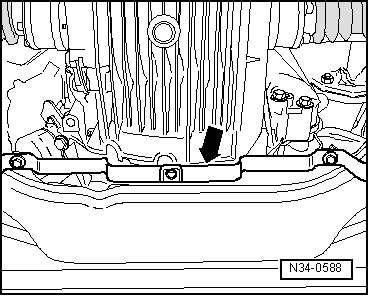

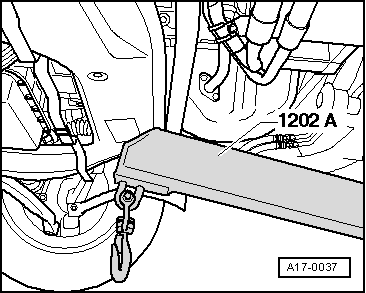

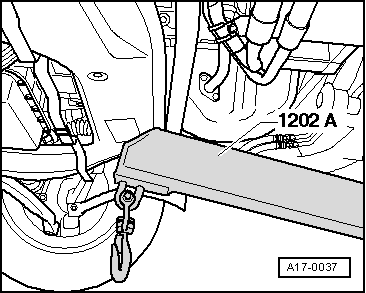

| Drip tray for workshop hoist -VAS 6208- |

| l

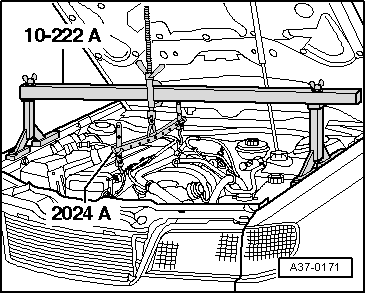

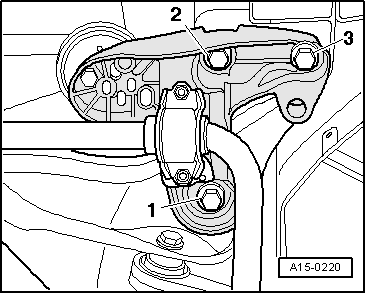

| Lock carrier must be in service position → Chapter. |

Caution | To prevent damage to the electronic components when disconnecting the battery: |

| Observe notes on procedure for disconnecting the battery. |

|

WARNING | Hot steam/hot coolant can escape - risk of scalding. |

| t

| The cooling system is under pressure when the engine is hot. |

| t

| To allow pressure to dissipate, cover filler cap on expansion tank with cloth and open carefully. |

|

| –

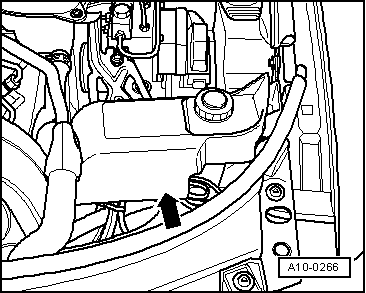

| Open filler cap on expansion tank. |

| –

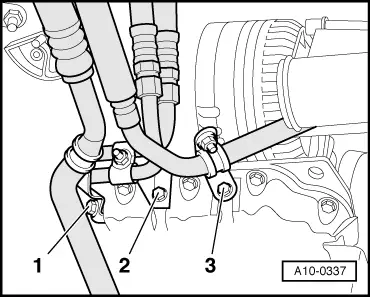

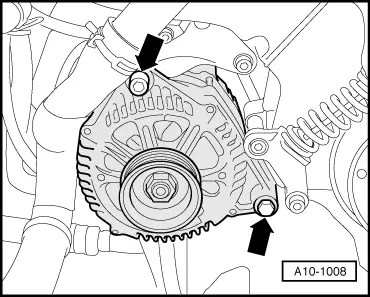

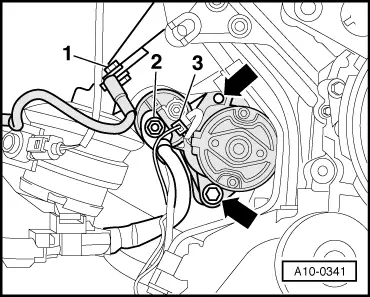

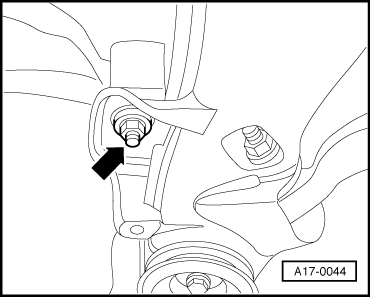

| Remove poly V-belt for power steering pump, alternator and viscous fan → Chapter. |

| –

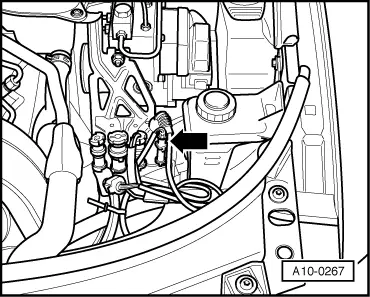

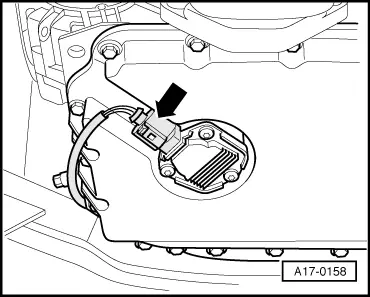

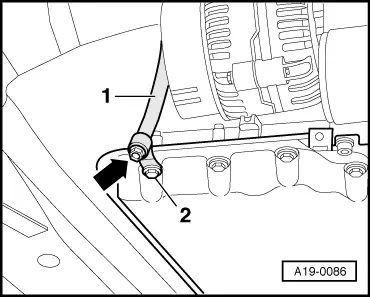

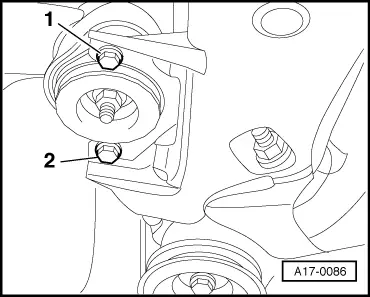

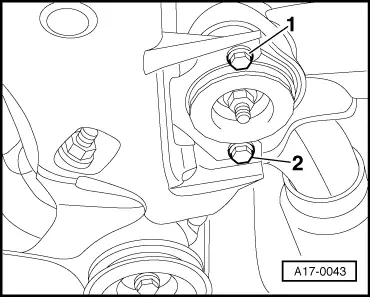

| Unbolt dipstick guide tube on cylinder head (right-side). |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution WARNING

WARNING