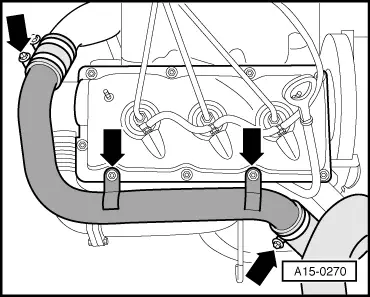

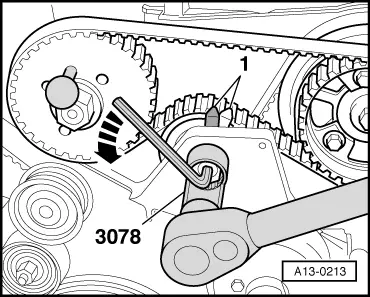

Caution | If a used belt runs in the opposite direction when it is refitted, this can cause breakage. |

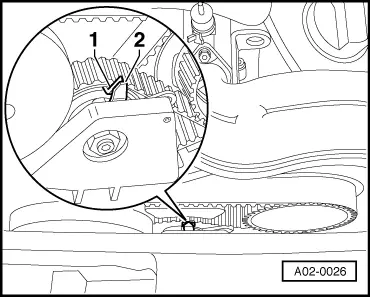

| Before removing, mark direction of rotation of toothed belt with chalk or felt-tipped pen for re-installation. |

|

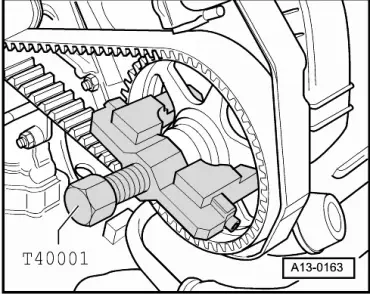

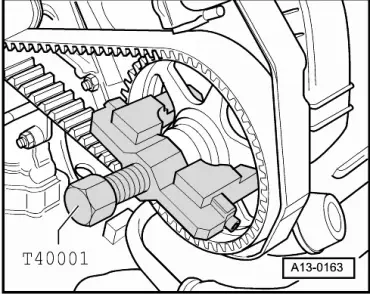

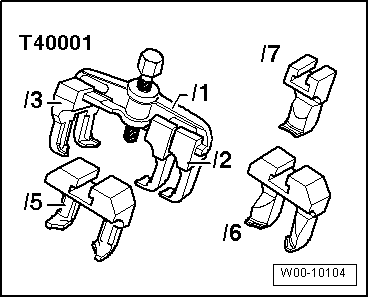

| –

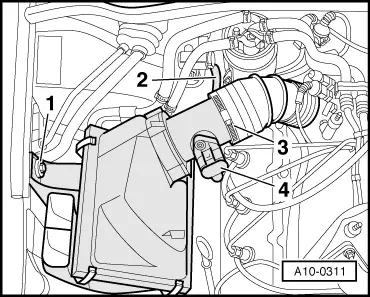

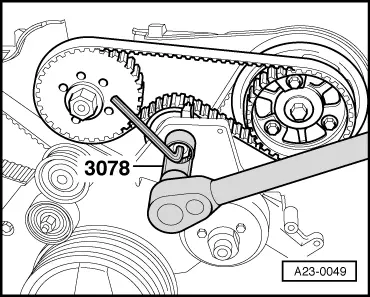

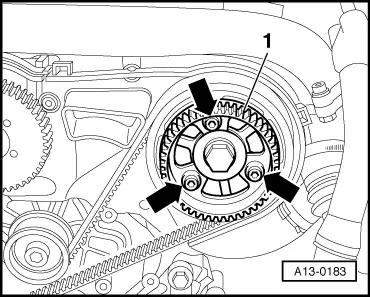

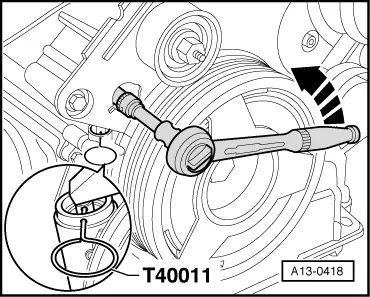

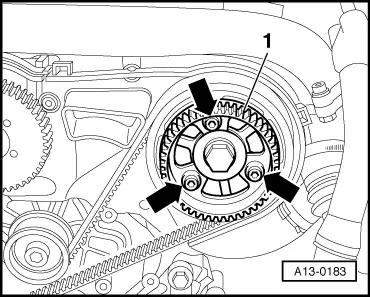

| Pull camshaft sprockets (left and right) off their tapers using two-arm puller -T40001- with claws -T40001/2-. |

| –

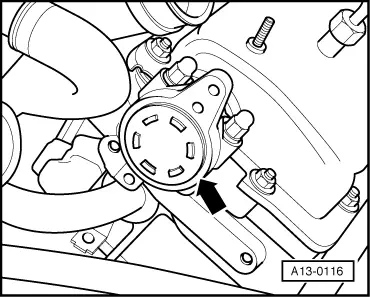

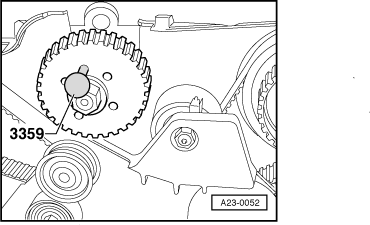

| Unbolt camshaft sprocket, left-side (cylinder bank 2). |

| –

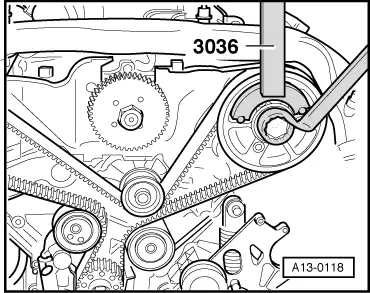

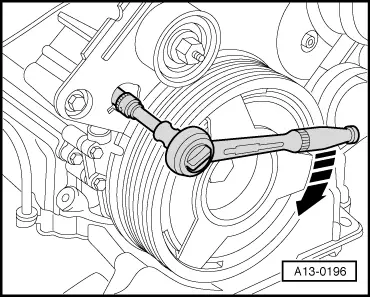

| Detach toothed belt from camshaft sprockets. |

| Installing (adjusting valve timing) |

| l

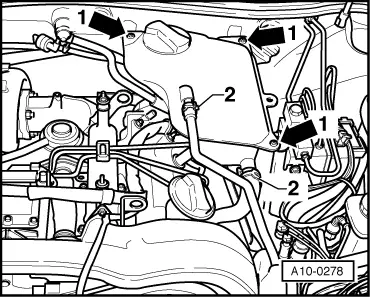

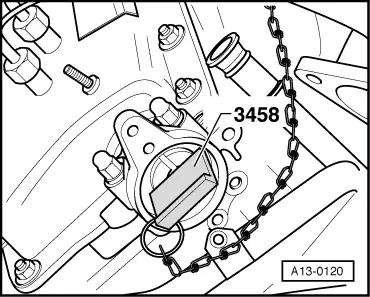

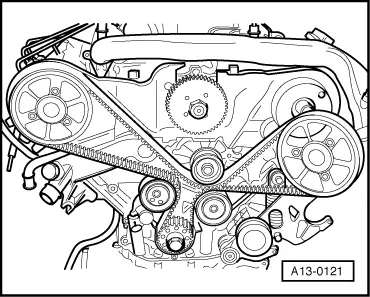

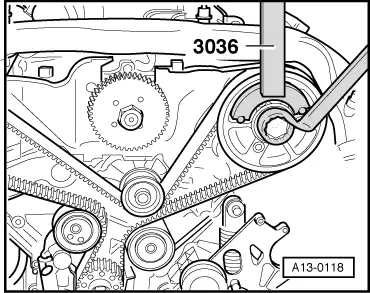

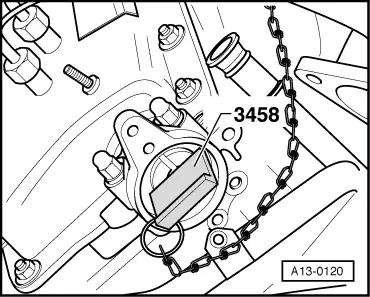

| Camshafts locked in position with camshaft holders -3458-. |

| l

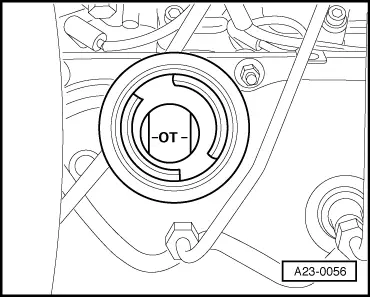

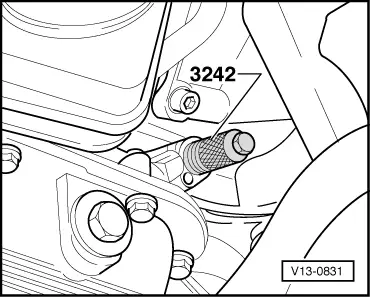

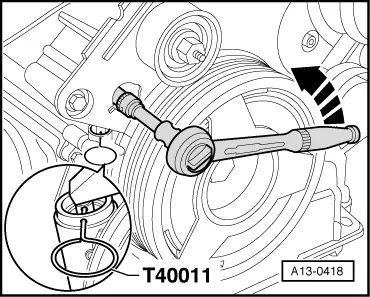

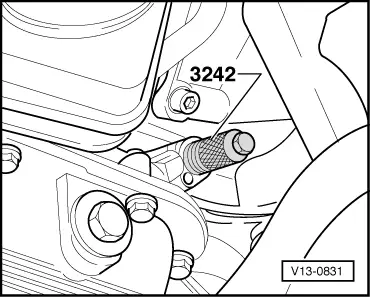

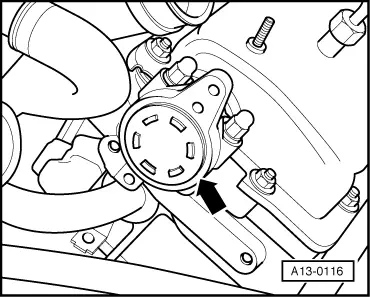

| Crankshaft locked in position with locking pin -3242-. |

| l

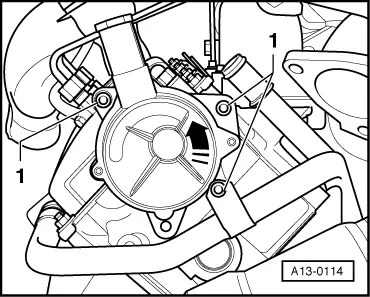

| Camshaft sprockets free to turn. |

| The valve timing must be adjusted as described below, even when the toothed belt has only been removed from the camshaft sprocket: |

| l

| The crankshaft must not be at “TDC” at any cylinder when the camshaft is turned. Otherwise, there is a risk of damage to valves and piston crowns. |

| l

| Do not use camshaft holders -3458- as counterhold tools. |

| l

| Adjustment can be performed with cold or warm engine. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING Caution

Caution