A4 Mk1

| Cylinder head - exploded view of components |

Note

Note| The illustration shows the left cylinder head for “engine generation III” with oil pipes. |

| 1 - | Cylinder head gasket |

| q | Renewing → Chapter „Removing cylinder head (left-side)“ and → Chapter „Removing cylinder head (right-side)“ |

| q | Installation position: Part No. towards cylinder head |

| q | If renewed, refill system with fresh coolant |

| 2 - | Cylinder head |

| q | Removing: left-side → Chapter; right-side → Chapter. |

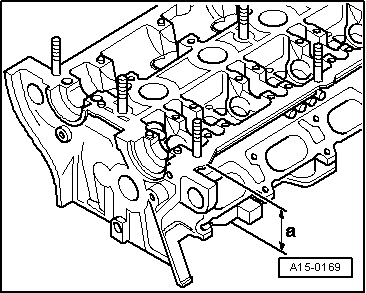

| q | Checking for distortion → Fig. |

| q | Machining limit → Fig. |

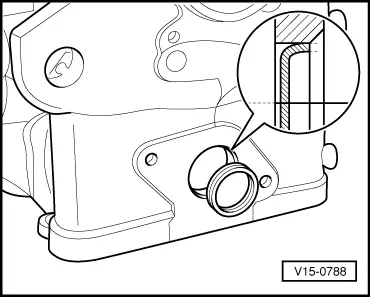

| q | Driving sealing cap into cylinder head → Fig. |

| q | Installing → Chapter |

| q | If renewed, refill system with fresh coolant |

| 3 - | Lifting eye |

| 4 - | 25 Nm |

| 5 - | Centering pin for intake manifold |

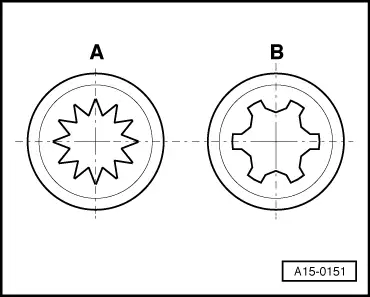

| 6 - | Cylinder head bolt |

| q | Renew |

| q | Different bolts → Fig. |

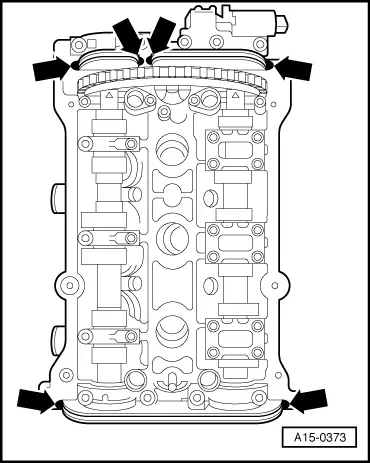

| q | Note correct sequence when loosening → Anchor and → Anchor |

| q | Note correct sequence when tightening → Anchor |

| 7 - | Intake manifold gasket |

| q | Renew |

| 8 - | Intake manifold |

| q | Removing and installing → Chapter |

| 9 - | 10 Nm |

| q | Tighten in stages and in diagonal sequence |

| 10 - | Filler cap |

| 11 - | Seal |

| q | Renew if damaged or leaking |

| 12 - | Rubber grommet |

| 13 - | Cover panel for cylinder head cover |

| 14 - | 10 Nm |

| q | Note correct sequence when tightening → Anchor or → Anchor |

| 15 - | Cylinder head cover |

| q | Removing and installing: left-side → Chapter, right-side → Chapter |

| 16 - | Gaskets for cylinder head cover |

| q | Renew if damaged or leaking |

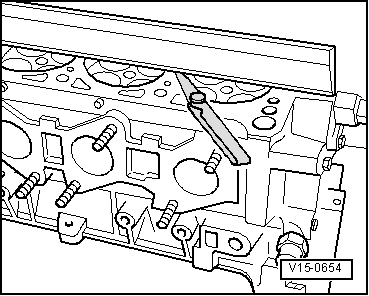

| q | Apply sealant at sealing points before installing → Fig.; Sealant → Parts catalogue |

| 17 - | Combination valve for secondary air system |

| 18 - | 10 Nm |

| 19 - | Gasket |

| q | Renew |

| 20 - | 10 Nm |

| 21 - | Coolant pipe (rear) |

| 22 - | O-ring |

| q | Renew |

| 23 - | Sealing cap |

| q | Removing and installing → Chapter |

|

|

|

|

|

|

|

|