A4 Mk1

| Removing sump (top section) |

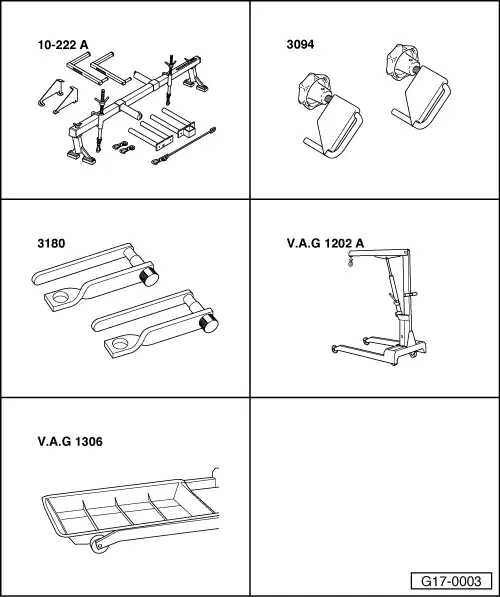

| Special tools and workshop equipment required |

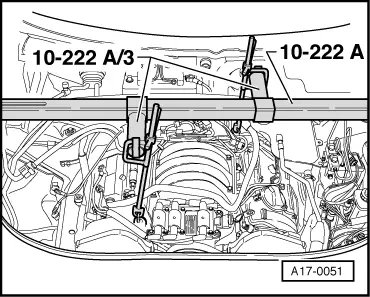

| t | Support bracket -10-222 A- and adapter -10-222 A/4- |

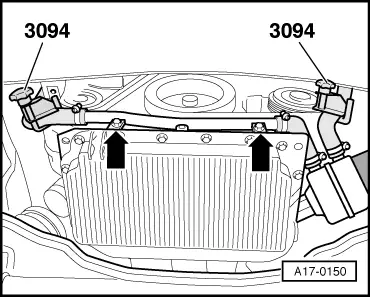

| t | Hose clamps for hoses up to 25 mm Ø -3094- |

| t | Retainer -3180- |

| t | Workshop hoist -VAS 6100- or -V.A.G 1202 A- |

| t | Drip tray for workshop hoist -VAS 6208- or -V.A.G 1306- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Caution

Caution WARNING

WARNING