A4 Mk1

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

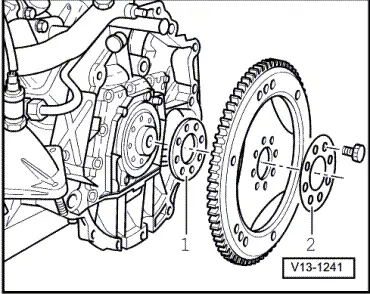

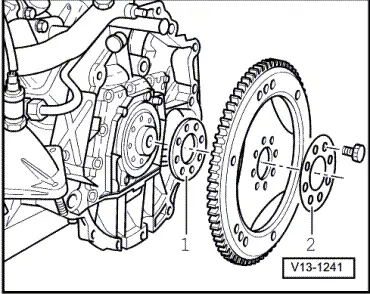

| Component | Nm | ||||||

| Drive plate to crankshaft | 60 + 180° 1)2) | ||||||

| Sealing plug in cylinder block | 10 | ||||||

| |||||||

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

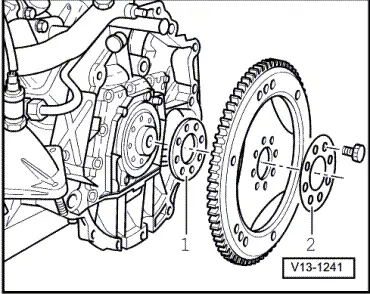

| Component | Nm | ||||||

| Drive plate to crankshaft | 60 + 180° 1)2) | ||||||

| Sealing plug in cylinder block | 10 | ||||||

| |||||||