A4 Mk1

|

Fuel supply system - front-wheel drive

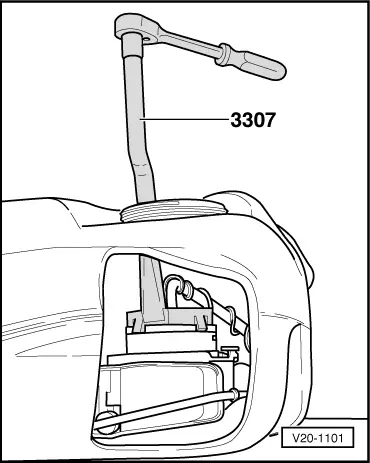

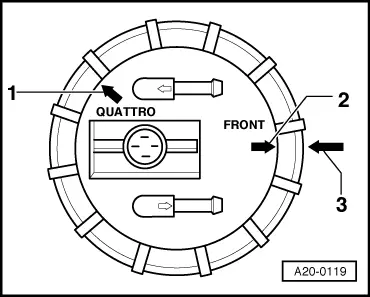

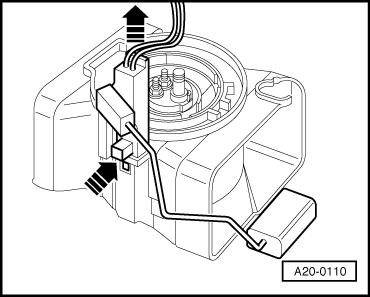

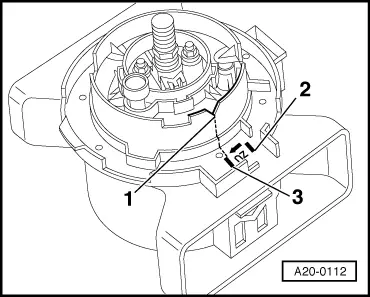

Removing and installing fuel delivery unit - vehicles with 6-cylinder engine

|

|

|

|

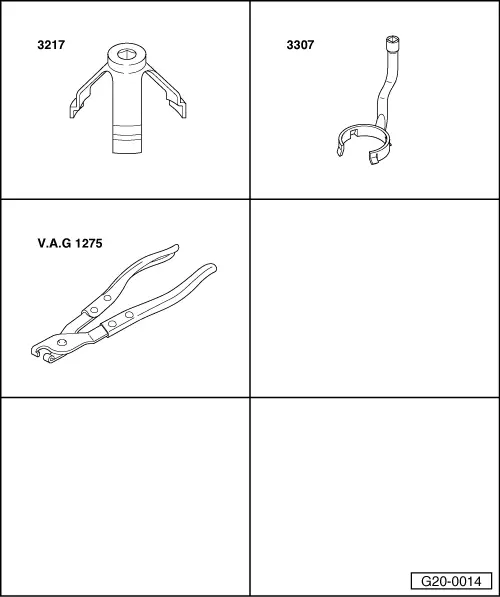

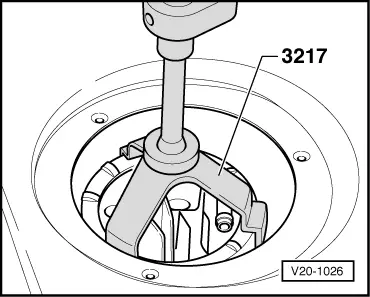

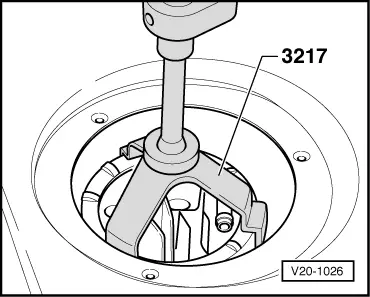

Special tools and workshop equipment required

|

|

|

|

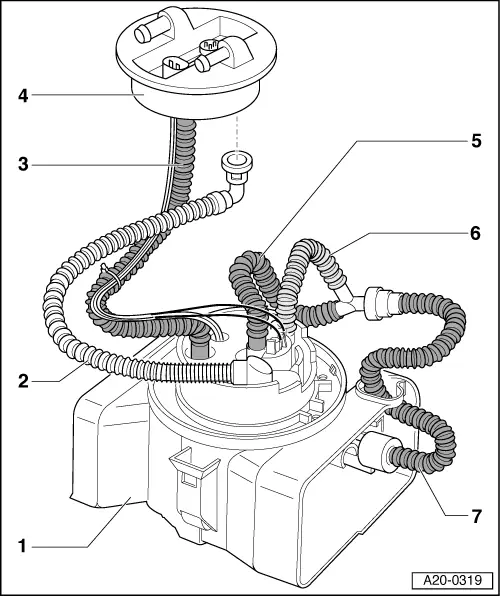

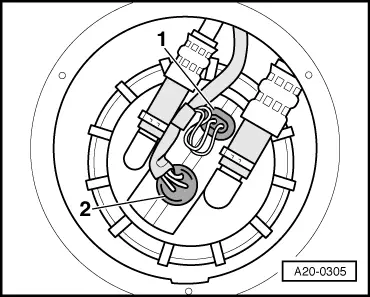

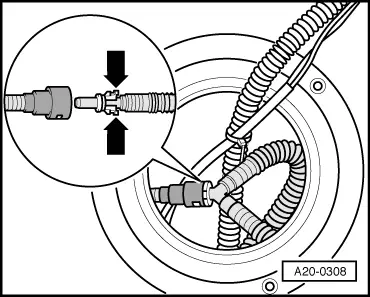

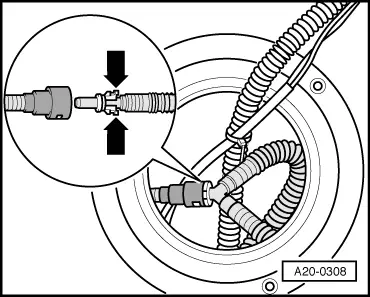

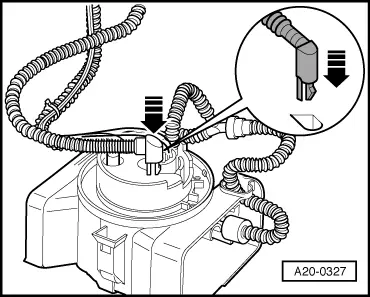

Note: The illustration shows the correct routing of hoses inside the tank.

Observe safety precautions. Observe rules for cleanliness => Page 20-3. Removing |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

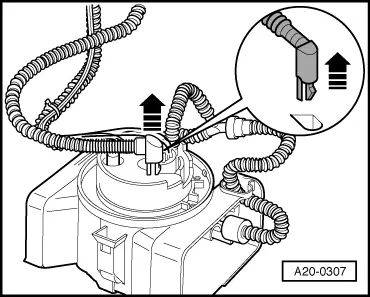

Note: Ensure that fuel hose going from baffle housing to Y-connector is engaged in retainer in outer section of baffle housing.

|

|

|

|

|

|

|