A4 Mk1

|

Readiness code

Produce readiness code

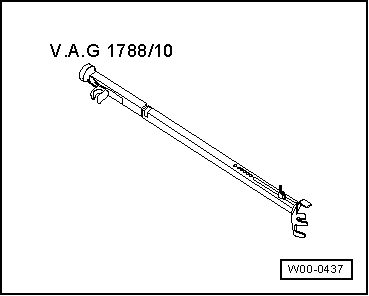

Special tools and workshop equipment required |

|

|

Preconditions:

Important note: If the test result "OK" is displayed immediately within a test step after selecting the display group the test has already run and the next operating step can be carried out. Operating step 1: Interrogating fault memory Test conditions:

|

| → When adjacent display appears: |

|

||

|

| → The display shows the number of stored faults or "No fault detected!". |

|

||

|

If no fault is stored:

If no fault is stored:

Operating step 2: Erasing fault memory Test conditions:

|

| → When adjacent display appears: |

|

||

Note: When erasing the fault memory the readiness code is reset and therefore must be produced again. |

| → When indicated on display: |

|

||

Adaption of throttle valve control unit to the engine control unit Test conditions:

|

| → When adjacent display appears: |

|

||

|

| → When adjacent display appears: |

|

||

|

| → Display readout: |

|

||||||||||||||||||||||||||||||||||||||||

Note on display zone 3: During adaption different figures are shown in display zone 3 which illustrate the relevant adaption condition. The deciding factor is not how the learning stage counter (display zone 3) behaves during the adaption process, but that specified value in display zone 4 of specified value "ADP OK" has been attained after adaption. If specified value "ADP OK" is attained:

Operating step 4: Adapt kickdown function 1) 1) Only on vehicles with automatic gearbox. Test conditions:

| |||||||||||||||||||||||||||||||||||||||||

| → When indicated on display: |

|

||

|

| → Display readout: |

|

||||||||||||||||||||||||||||||||||||||||

|

Note: You will now be instructed to: "Confirm kickdown".

Note: During adaption the kick-down point "Kick-down ADP is running" is displayed on V.A.G 1551. After successful adaption of the kick-down point the V.A.G 1551 shows "Kick-down ADP OK".

Note on display zone 4: If "ERROR" can be displayed, if e.g. accelerator pedal is not pressed when instructed by tester, or if accelerator pedal was released while adaption was already running but process was not yet complete. In both cases it is necessary to exit the "Basic setting" mode and restart the adaption process afresh. If specified value "ADP OK" is attained:

Operating step 5: Check operating status of lambda control

Note: If necessary, reselect the engine control unit with "address word" 01 after starting the engine and initiate function "basic setting" with "04".

Test conditions:

| |||||||||||||||||||||||||||||||||||||||||

| → When adjacent display appears: |

|

||

|

| → When adjacent display appears: |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Note: Several minutes may pass until reaching a diagnostic result.

Notes:

Operating step 6: Diagnosis of ageing of lambda probe upstream of catalytic converter Test conditions:

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| → When indicated on display: |

|

||

|

| → Display readout: |

|

||||||||||||||||||||||||||||||||||||||||

Note: Several minutes may pass until reaching a diagnostic result.

If specified value "B1-S1 OK" is attained:

Operating step 7: Diagnosis of lambda probe condition downstream of catalytic converter Test conditions:

| |||||||||||||||||||||||||||||||||||||||||

| → When adjacent display appears: |

|

||

|

| → Display readout: |

|

||||||||||||||||||||||||||||||||||||||||

If specified value "B1-P2 OK" is attained:

Operating step 8: Diagnosis of lambda control system Test conditions:

| |||||||||||||||||||||||||||||||||||||||||

| → When indicated on display: |

|

||

|

| → Display readout: |

|

||||||||||||||||||||||||||||||||||||||||

If specified value "Syst. OK" is attained:

Operating step 9: Diagnosis of ageing of lambda probes downstream of catalytic converter Test conditions:

| |||||||||||||||||||||||||||||||||||||||||

| → When indicated on display: |

|

||

|

| → Display readout: |

|

||||||||||||||||||||||||||||||||||||||||

If specified value "B1-P2 OK" is attained:

Operating step 10: Diagnosis catalytic converter Test conditions:

| |||||||||||||||||||||||||||||||||||||||||

| → When indicated on display: |

|

||

|

| → Display readout: |

|

||||||||||||||||||||||||||||||||||||||||

Note: The time of the test of the catalytic converter diagnosis is approx. 60 seconds.

If the specified value "Cat B1 OK" is attained:

Operating step 11: Diagnosis of fuel tank breather valve

Test conditions:

| |||||||||||||||||||||||||||||||||||||||||

| → When indicated on display: |

|

||

|

| → Display readout: |

|

||||||||||||||||||||||||||||||||||||||||

Note: If the test is not initiated or if the display jumps from "Test ON" to Test "OFF" accelerate briefly, test is repeated.

If specified value "TEV OK" is attained:

Operating step 12: Diagnosis of secondary air system Test conditions:

Note: If the diagnosis of the secondary air system the secondary air pump runs several seconds. | |||||||||||||||||||||||||||||||||||||||||

| → When adjacent display appears: |

|

||

|

| → Display readout: |

|

||||||||||||||||||||||||||||||||||||||||

Note: The time of the test of the secondary air system is approx. 60 seconds.

If specified value "Syst. OK" is attained:

| |||||||||||||||||||||||||||||||||||||||||

| → Display readout (function selection): |

|

||

|

Operating step 13: Read out readiness code

|