A4 Mk1

| → Indicated on display: |

|

||

Note: During the basic setting the engine control unit closes the activated charcoal filter solenoid valve (ACF valve -N80) and switches off the air conditioner compressor. |

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

If the specification is obtained:

Reading Display Group 002

Reading Display Group 002

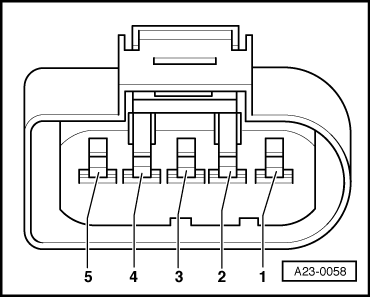

Testing power supply to air mass meter | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

Note: The air mass meter receives its voltage supply via the fuel pump relay. If the reading does not match the battery voltage:

=> Current flow diagrams, Electrical fault finding and Fitting locations binder If specification is met:

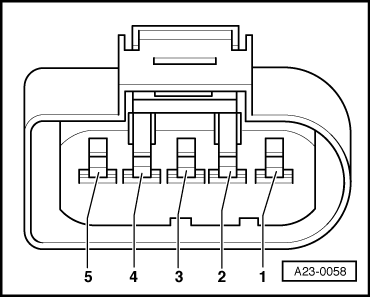

Testing earth connection |

|

|

Note: Socket 3 on the connector is the earth connection from the engine control unit. If the specification is not attained:

|

|

|

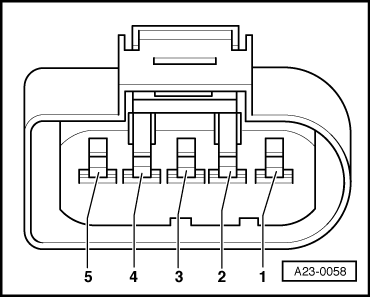

If the specification is not attained:

Testing wiring for air mass meter Note: The signal wire is also tested in the wiring test. |

|

||||||||||||||||||

=> Current flow diagrams, Electrical fault finding and Fitting locations binder

|