A4 Mk1

|

Readiness code

Generating readiness code

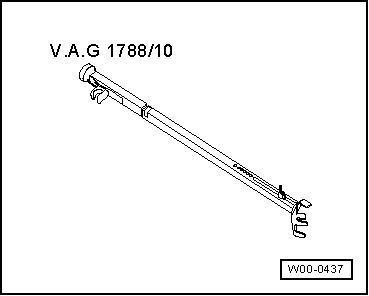

Special tools and workshop equipment required |

|

|

Test requirements

Work step 1: interrogate fault memory

|

| → Indicated on display: |

|

||

|

| → The number of faults stored or "No fault recognised!" will be shown on the display. |

|

||

|

If a fault is stored:

If no faults are stored:

Work step 2: erase fault memory

|

| → Indicated on display: |

|

||

Note: If the fault memory is erased, the readiness code is set back and therefore has to be regenerated. |

| → Indicated on display: |

|

||

The readiness code can be generated in two ways:

or

Work step 3: diagnosis of fuel tank breather valve Test conditions

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||||||||||||||||||||||||||||||||||||||||

If the specification "TBV O.K." is attained:

Work step 4: diagnosis of fuel supply system

| |||||||||||||||||||||||||||||||||||||||||

| → Indicated on display: |

|

||

|

| → Indicated on display |

|

||||||||||||||||||||||||||||||||||||||||

If the specification "Syst. OK" is obtained in display zone 4:

Work step 5: diagnosis of lambda probe heating | |||||||||||||||||||||||||||||||||||||||||

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

| → Indicated on display |

|

||||||||||||||||||||||||||||||||||||||||

If the specification "B1-P1 OK" is obtained in display zone 4:

Work step 7: diagnosis of condition of lambda probe after catalytic converter

| |||||||||||||||||||||||||||||||||||||||||

| → Indicated on display: |

|

||

|

| → Indicated on display |

|

||||||||||||||||||||||||||||||||||||||||

If the specification is obtained: B1-P2 OK in display zone 2

Work step 8: diagnosis of lambda control system

| |||||||||||||||||||||||||||||||||||||||||

| → Indicated on display: |

|

||

|

| → Indicated on display |

|

||||||||||||||||||||||||||||||||||||||||

If the specification "Syst. OK" is obtained in display zone 4:

Work step 9: diagnosis of catalytic converter | |||||||||||||||||||||||||||||||||||||||||

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||||||||||||||||||||||||||||||||||||||||

Note: The diagnostic test of the catalytic converter takes approx. 60 seconds.

If the specification "Cat B1 OK" is obtained in display zone 4 :

Work step 10: diagnosis of secondary air system | |||||||||||||||||||||||||||||||||||||||||

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||||||||||||||||||||||||||||||||||||||||

Note: The diagnostic test of the secondary air system takes approx. 60 seconds.

If the specification "Syst. OK" is obtained in display zone 4:

Work step 11: reading off readiness code.

| |||||||||||||||||||||||||||||||||||||||||