A4 Mk1

|

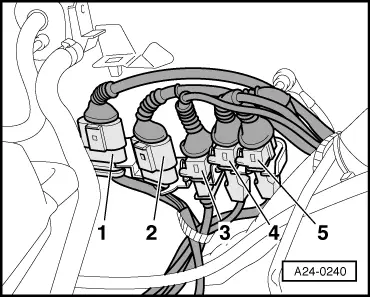

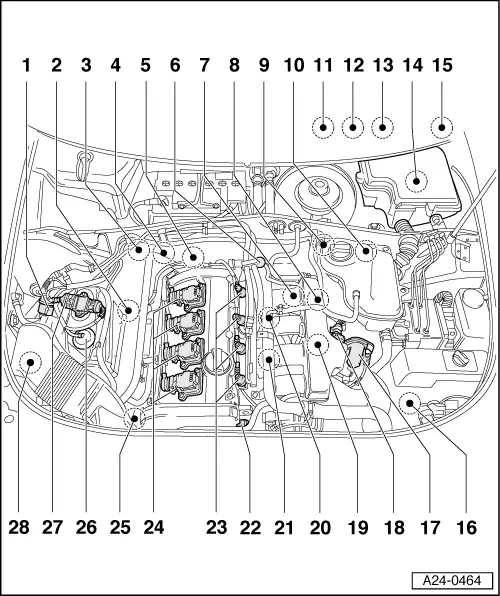

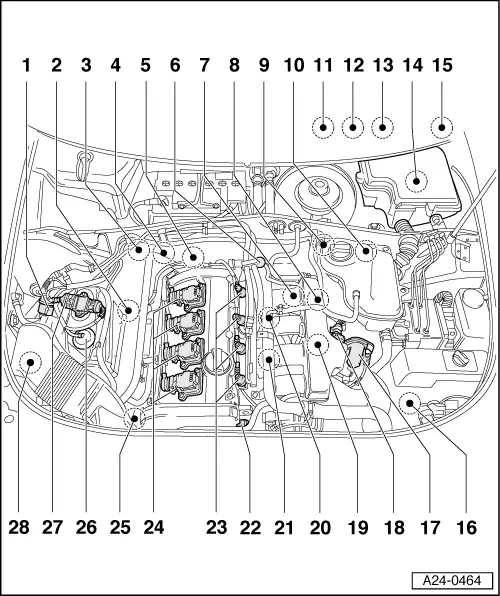

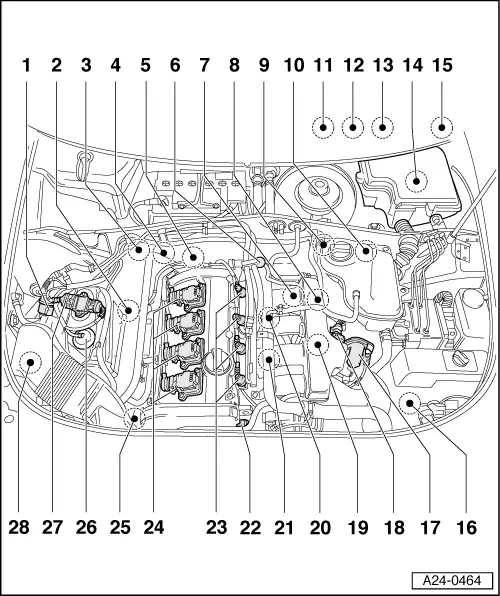

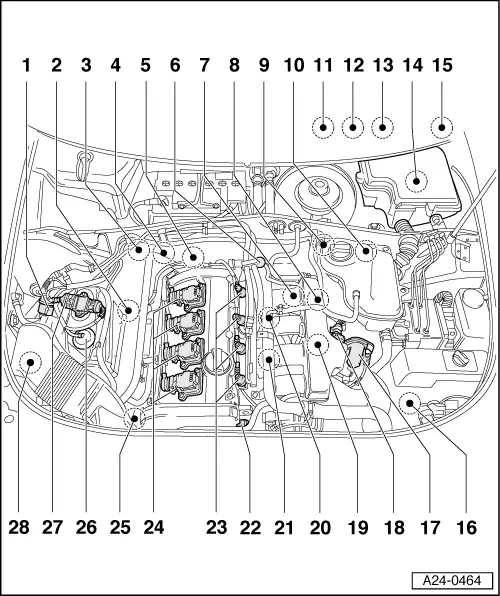

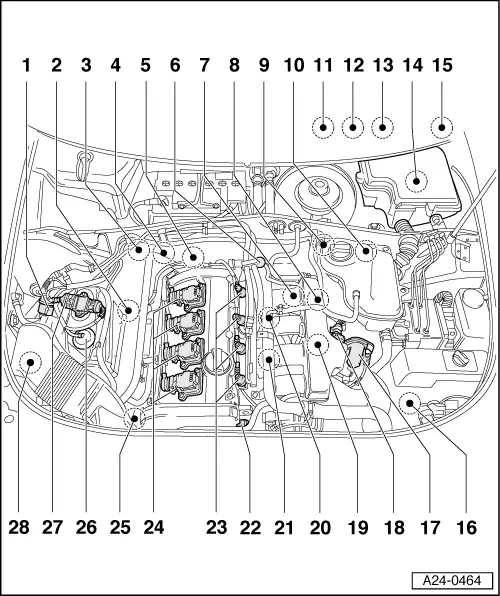

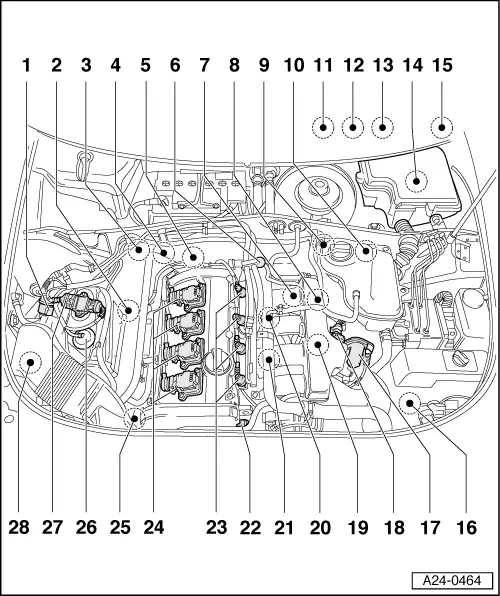

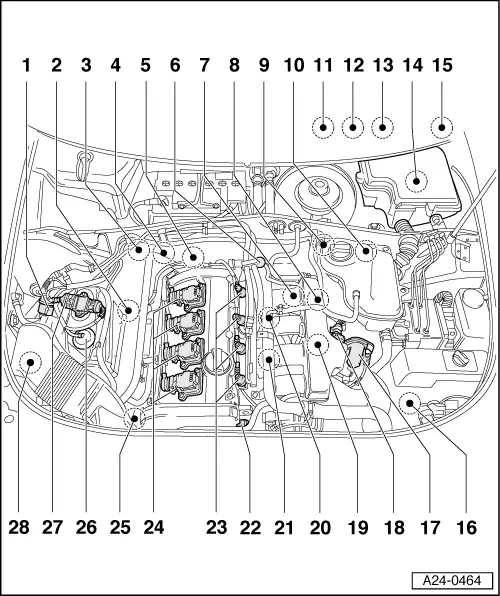

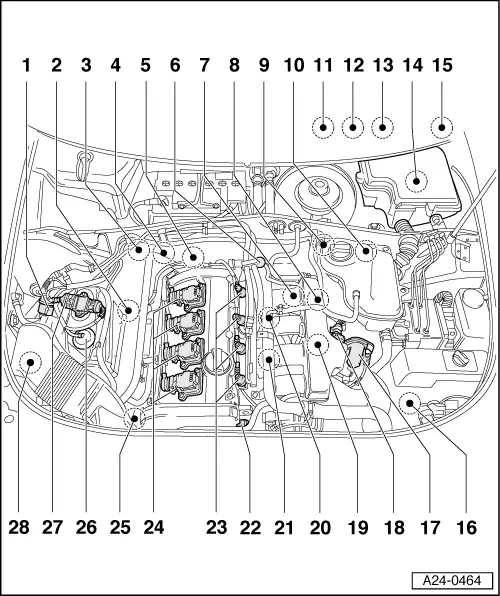

Servicing Motronic injection system

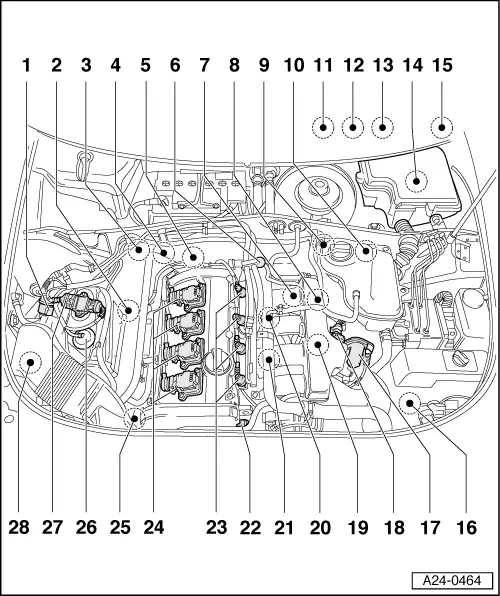

Fitting locations overview

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

=> 4-Cylinder engine (5-valve turbo), Mechanics; Repair group 26; Testing secondary air system

|

|

|

|

|

|

|

|

|

|

|

|

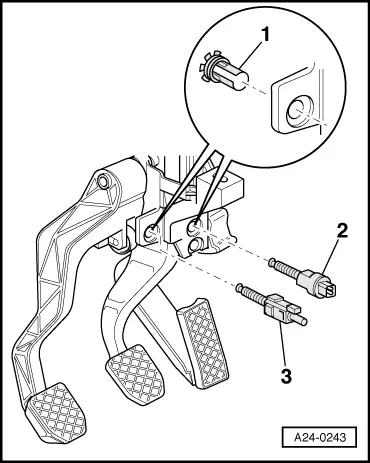

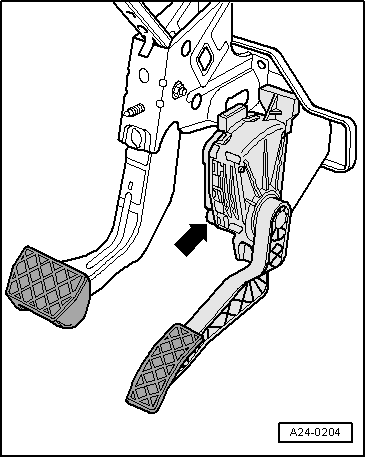

→ Fig.2 Fitting location of accelerator position senders -G79 and -G185 |

|

|

|

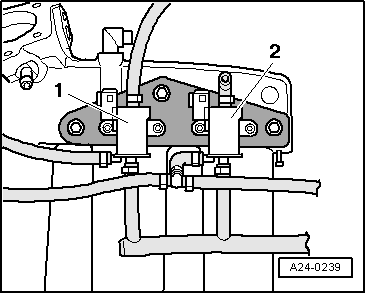

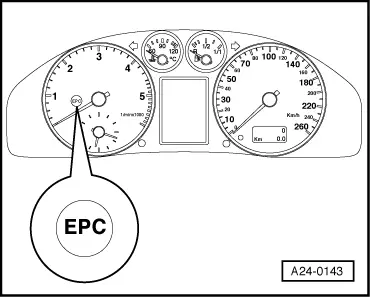

→ Fig.4 Fitting location of electronic throttle control warning lamp -K132 |

|

|

|

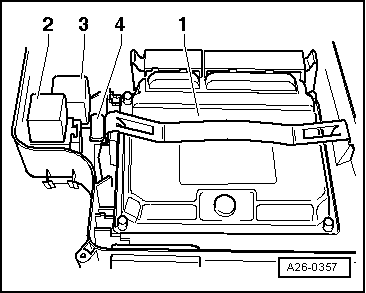

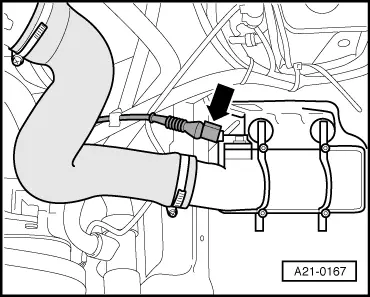

→ Fig.7 Fitting location ofcharge pressure sender -G31 Charge pressure sender -G31 -arrow- is installed at top of charge air cooler. |