A4 Mk1

|

Readiness code

Generating readiness code

|

|

|

|

Special tools and workshop equipment required

Requirements:

Work sequence

Work step 1: interrogate fault memory

|

| → Indicated on display: |

|

||

|

| → The number of faults stored or "No fault recognised!" will be shown on the display. |

|

||

|

If a fault is stored:

If no faults are stored:

Work step 2: erase fault memory

|

| → Indicated on display: |

|

||

Note: If the fault memory is erased, the readiness code is set back and therefore has to be regenerated. |

| → Indicated on display: |

|

||

Work step 3: adjust the throttle valve control part to the engine control unit

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||||||||||||||||||||||||||||||||||||||||

If the specification "ADP O.K." is attained:

Work step 4: diagnosis of fuel tank breather system

Note: After starting the engine, enter address word "01" to re-select the engine control unit if necessary, and enter "04" to select the function "Introduction of basic setting". | |||||||||||||||||||||||||||||||||||||||||

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||||||||||||||||||||||||||||||||||||||||

Note: If the test does not start or if the display jumps from "Test ON" to "Test OFF", press the accelerator briefly. The test will now be repeated.

If the specification "TBV O.K." is attained:

Work step 5: check lambda control operation

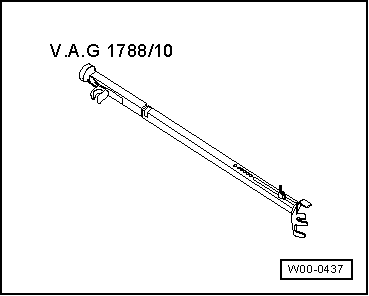

Note: To obtain the higher engine speed specified above, use the speed regulator V.A.G 1788/10. | |||||||||||||||||||||||||||||||||||||||||

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Note: The readouts can be obtained more quickly by increasing engine speed.

Explanation of 3-figure displays in Display Group 030

Notes:

If the specifications are obtained:

Work step 6: diagnosis of lambda probe ageing (cycle duration)

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||||||||||||||||||||||||||||||||||||||||

Note: It may take a few minutes before a diagnosis result is obtained.

If the specification "B1-P1 O.K." is attained:

Work step 7: diagnosis of lambda control system

| |||||||||||||||||||||||||||||||||||||||||

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||||||||||||||||||||||||||||||||||||||||

If the specification "SYST. O.K." is attained:

Work step 8: diagnosis of catalytic converter

| |||||||||||||||||||||||||||||||||||||||||

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||||||||||||||||||||||||||||||||||||||||

Note: The diagnostic test of the catalytic converter takes approx. 60 seconds.

If the specification "Cat B1 O.K. is attained:

Work step 9: diagnosis of secondary air system

| |||||||||||||||||||||||||||||||||||||||||

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||||||||||||||||||||||||||||||||||||||||

If the specification "SYST. O.K." is attained:

| |||||||||||||||||||||||||||||||||||||||||

| → Indicated on display (function selection): |

|

||

|

Work step 10: read off readiness code

|