-

‒ Place the injector which is to be tested into measuring glass of injection quantity tester V.A.G 1602.

-

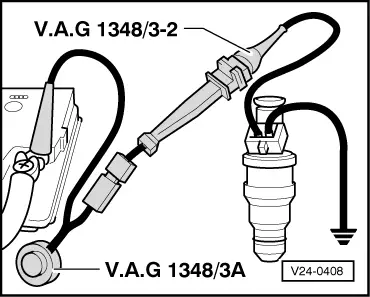

‒ → Connect one of the injector contacts to engine earth using test cable and crocodile clamp from V.A.G 1594.

-

‒ Connect second injector contact to positive using remote control V.A.G 1348/3 A, adapter cable V.A.G 1348/3-2 and auxiliary cable.

-

‒ Start final control diagnosis and actuate fuel pump relay -J17 =>Page01-45. The fuel pump should run.

-

‒ Check injectors for leaks (visual check). When the fuel pump is running, only 1 or 2 drops a minute should escape from each injector.

-

‒ If the fuel loss is greater, switch off the fuel pump (terminate final control diagnosis) and renew the faulty injector. Removing and installing injectors =>Page 24-26.

-

‒ If necessary re-start the final control diagnosis.

Note:

The final control diagnosis cannot be re-started until the ignition has been switched off briefly.

-

‒ Activate the V.A.G 1348/3 A remote control for 30 seconds.

-

‒ Perform measurements on all injectors.

-

‒ Once all four injectors have been actuated, place measuring glasses on a level surface.

Engine code Specified value

ADP and ADR 85...105 ml

AEB 130...150 ml

-

‒ If measured values for one or more injectors are outside tolerance, switch off fuel pump (terminate final control diagnosis) and replace defective injector.

-

‒ If the measured values for all the injectors are outside the tolerance range, check the fuel pressure =>Page 24-18.

Note:

When checking the injection quantity, also check the spray pattern. The spray pattern should be the same for all the injectors.

Installation of the fuel manifold together with injectors is performed in the reverse sequence. The following points should be noted when installing:

-

● Renew the O-rings at all opened connections.(When renewing the front O

ring, make sure not to remove the plastic cap from the injector head. The O-ring must be pulled off over the plastic cap.)

-

● Moisten the O-rings with clean engine oil.

-

● Make sure that the injectors are installed in the correct positions. (With the engine codes ADR and AEB, the electrical connections are secured against twisting by a plastic part between cylinders 1 and 2 and cylinders 3 and 4).

-

● Check to make sure that the retainer clamps are properly seated.

|