A4 Mk1

|

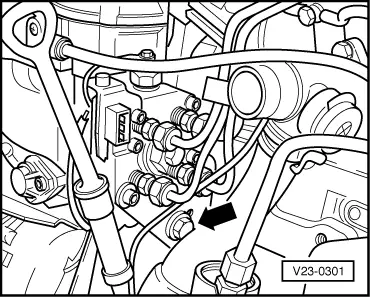

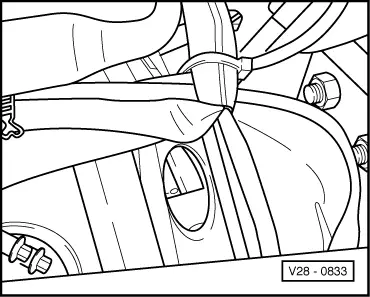

Servicing Diesel direct injection system

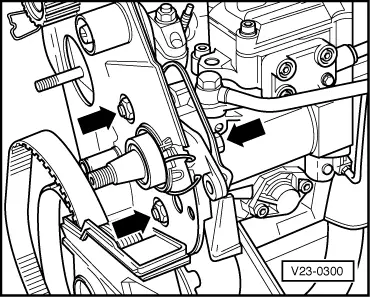

Removing and installing injection pump: engine codeAFF, AHU, AFN,AVG

Removing injection pump |

|

|

=> General body repairs, Exterior; Repair group 50; Body, front; Lock carrier - service position

|

|

|

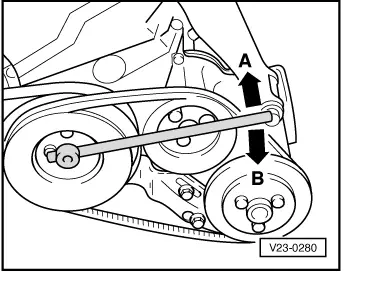

Engine removed - vehicles with manual gearbox: |

|

|

Engine removed - vehicles with automatic gearbox: |

|

|

|

|

|

|

|

|

|

|

|

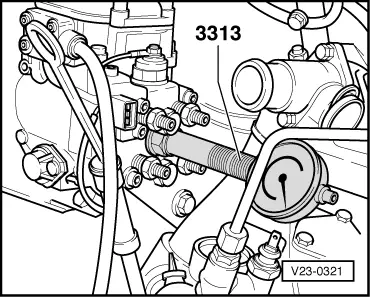

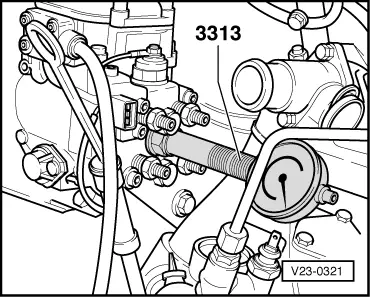

Note: Use slotted ring spanner 3035 to remove high pressure fuel pipes. |

|

|

|

|

|

|

|

|

|

|

|

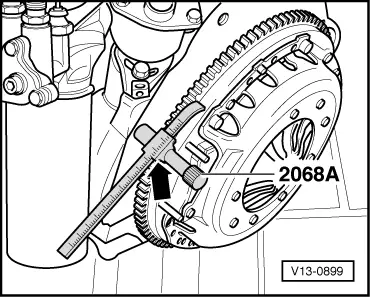

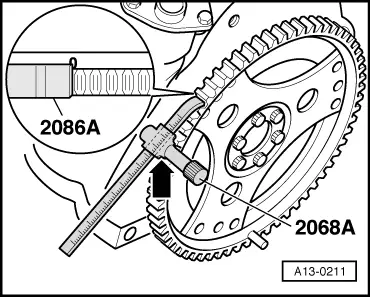

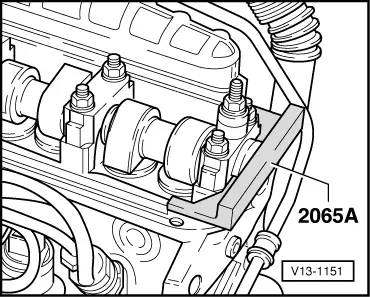

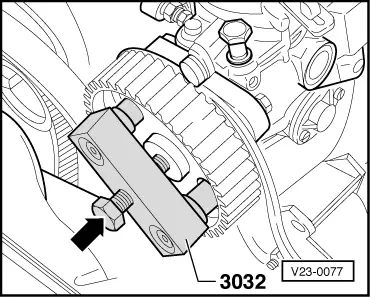

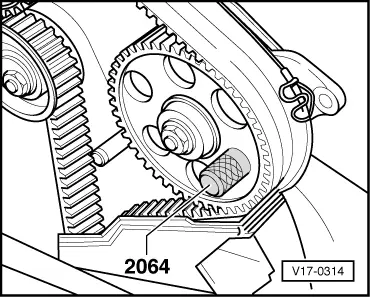

Adjusting injection pump |

|

|

|

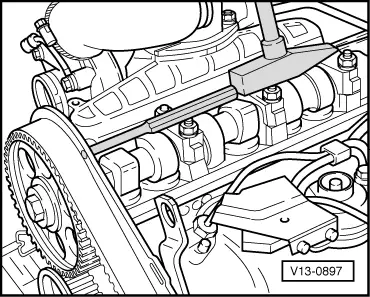

Checking and adjustment conditions

|

|

|

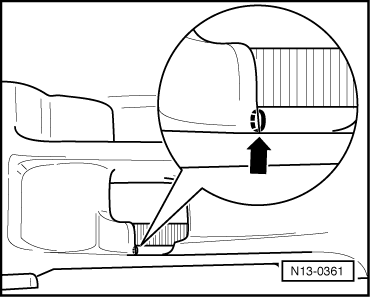

Note: Alignment with the TDC mark is achieved by rotating the crankshaft in the direction of engine revolution. If the crankshaft is rotated too far by mistake (i.e. beyond the TDC mark), adjust as follows: |

|

|

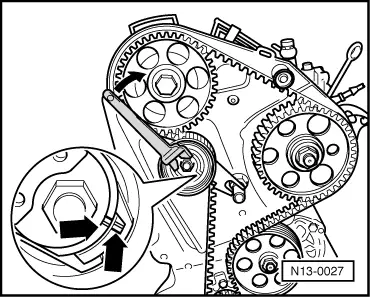

Tightening torques:

|

|

|

|

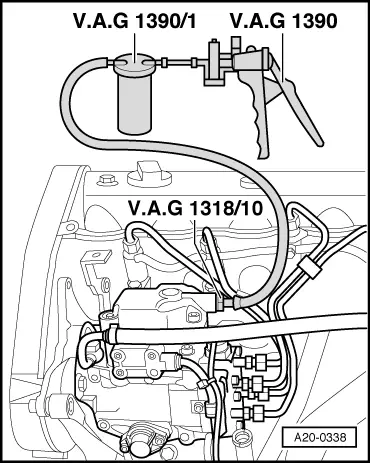

→ Fill injection pump with clean diesel fuel as follows:

|