-

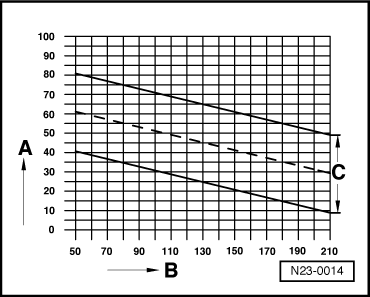

‒ → The commencement of injection in display zone 2 depends on the fuel temperature value in display zone 9.

- Specified value: => Range C in illustration

- A - Display zone 2 Commencement of injection

- B - Display zone 9 Fuel temperature

Notes:

-

◆ If the commencement of injection is advanced, turn the injection pump in the engine's direction of rotation, if the commencement of injection is retarded, turn against the direction of rotation.

-

◆ If injection start is within specified range C when tested, no adjustment is required. After repairs, such as the removal and installation of the injection pump, the adjustment of the timing, the commencement of injection should be set to the mean valve (dashed line) in specified range -C-.

If the commencement of injection (timing) is outside the specification tolerances, adjust the commencement of injection as follows:

Adjust the commencement of injection

-

‒ Remove the upper toothed belt guard, if this has not already been done.

-

‒ Loosen the injection pump securing bolts by approx. one turn, leaving the easiest bolt to reach till last.

-

‒ By hand, hold the injection pump under tension in the direction to be adjusted.

-

‒ Carefully loosen the last securing bolt until the pump can be turned slightly and then retighten the securing bolt.

-

‒ Check the setting in the function "Basic Setting 04".

|