A4 Mk1

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

| → Specified value: 230 ... 370 mg/stroke |

|

||

|

If specified value is not attained:

If specified value is attained:

Important:

Secure fault reader to the rear seat and operate from this location. When doing this, always observe the relevant safety precautions Page 23-1.

|

| → Specification for display zone 4: 100 % (accelerator pedal position) |

|

||

|

If specified value is not attained:

|

| → Specification for display zone 3: Boost pressure |

|

||

|

If specified value is not attained:

|

| → Specification for display zone 1: > 800 mg/stroke (intake air mass) |

|

||

|

greater than 750 mg/stroke greater than 800 mg/stroke If specified value is not attained:

If display zone 1 shows a constant reading of 425 mg/stroke (fixed substitute value):

|

|

||||||||||

If the specified values are not obtained:

|

|

|||||||||||||

|

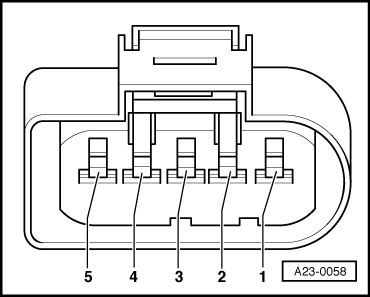

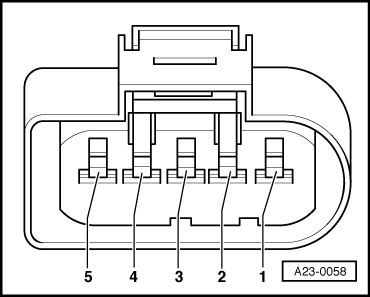

The following wiring connections are to be checked for open circuits and/or short to positive or negative.

=> Current Flow Diagrams, Electrical Fault-finding and Fitting Locations binder |