| –

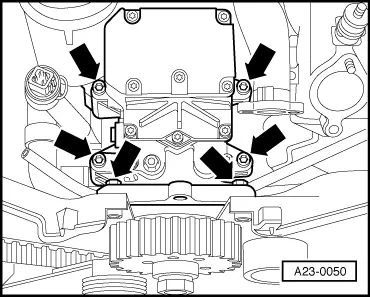

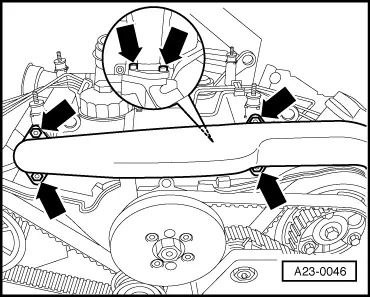

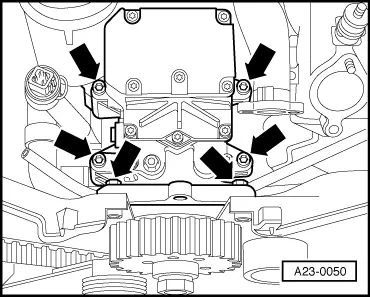

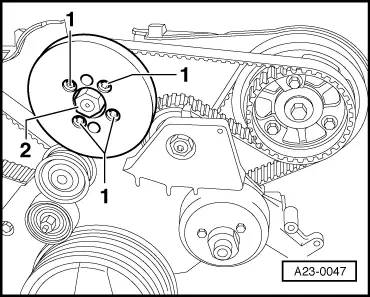

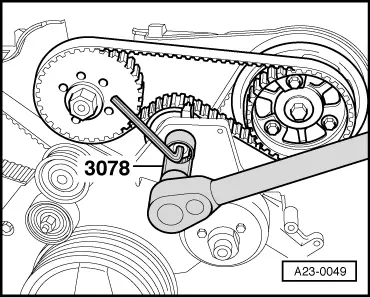

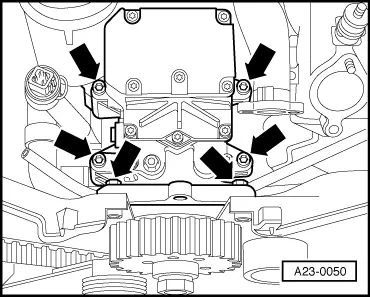

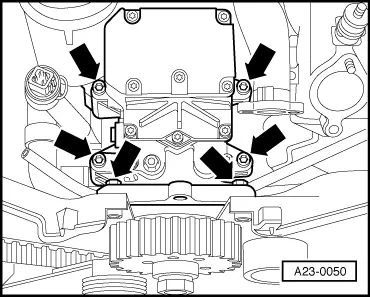

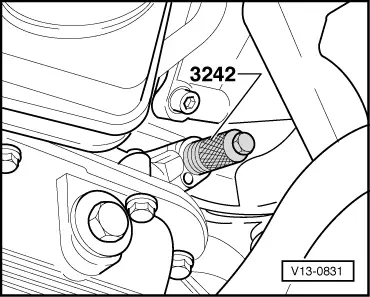

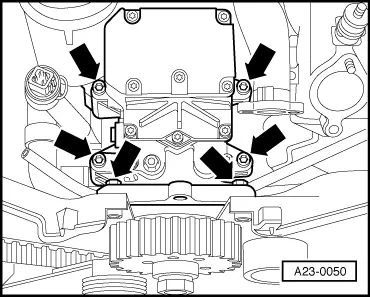

| Mount injection pump on engine and bolt it in place. |

| t

| Tightening torque: bolts on crankcase: 20 Nm |

| t

| Tightening torque: bolts on toothed belt cover: 10 Nm |

| –

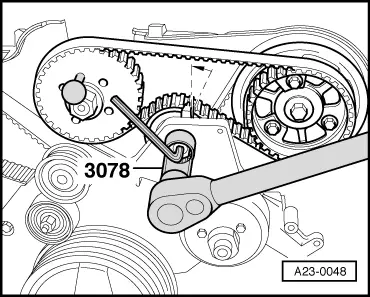

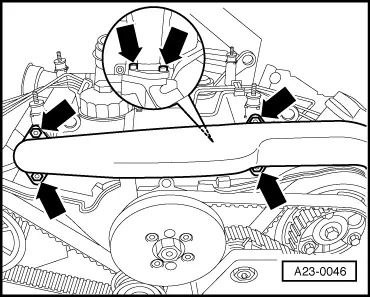

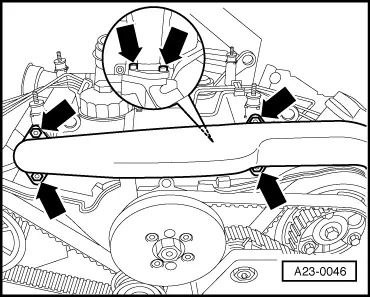

| After tightening injection pump mountings, fit injector pipes one at a time, working from bottom to top and secure using torque wrench -V.A.G 1331- and 17 mm open ring spanner attachment (e.g. Stahlwille 733/10). |

| t

| Tightening torque: 30 Nm |

Note | t

| Incorrect assembly will distort the taper seats of the pipe unions. (Risk of leaks) |

| t

| When tightening the connections, make sure the injector pipes are not twisted or under tension. |

| t

| Secure the retaining clips on the injector pipes in their original positions and without tension. |

| –

| Secure injector pipes to injectors. |

| t

| Tightening torque: 30 Nm |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note