A4 Mk1

|

|

|

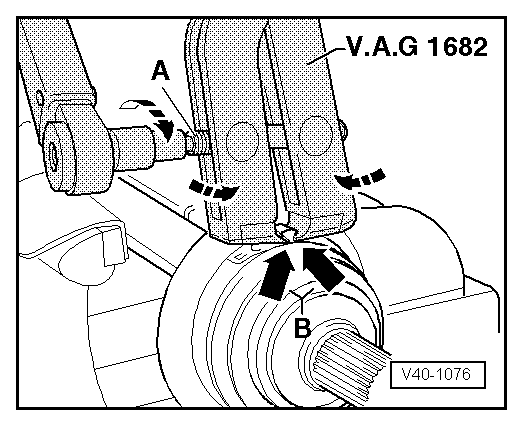

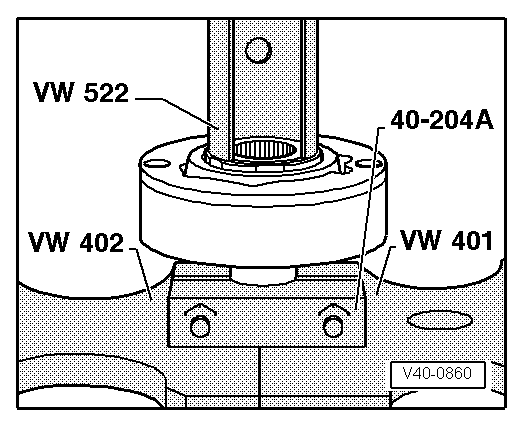

→ Fig.3 Pressing off inner constant velocity joint Notes:

|

|

|

|

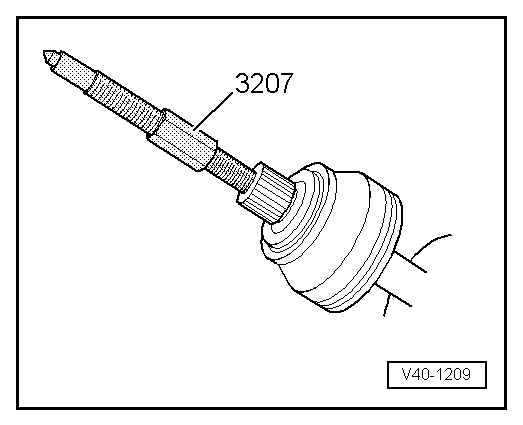

→ Fig.4 Pressing on inner constant velocity joint

Note: Chamfer at ID of ball hub (splines) must face contact collar of drive shaft. |

|

|

|

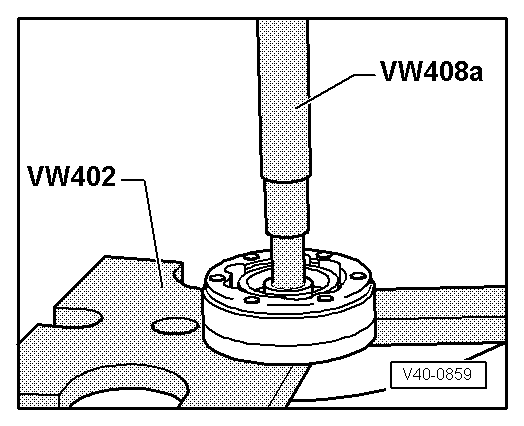

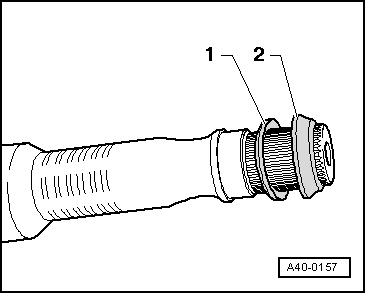

Fig.5 → Installation position of spacer ring and dished washer (wheel end)

|