| –

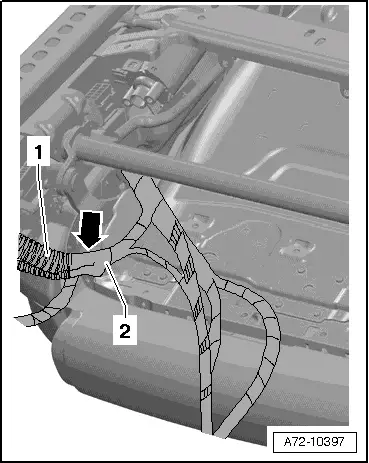

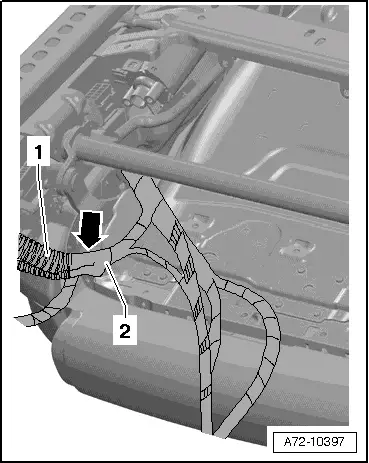

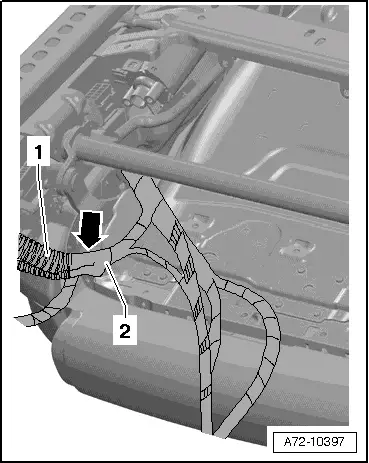

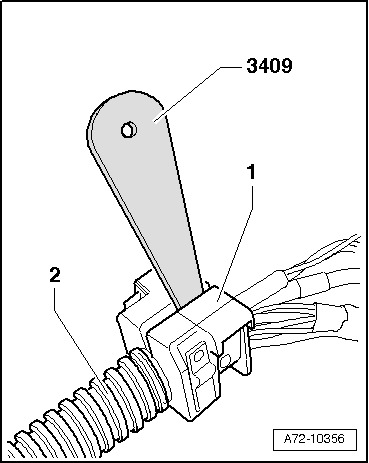

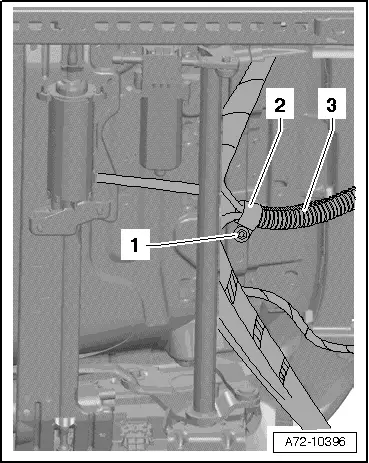

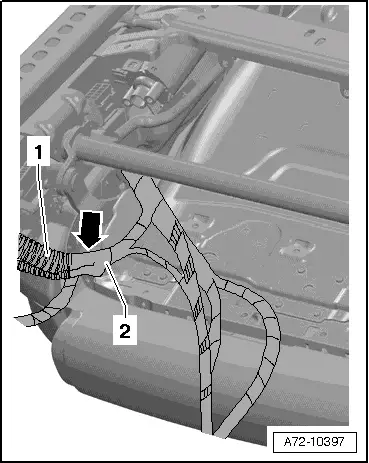

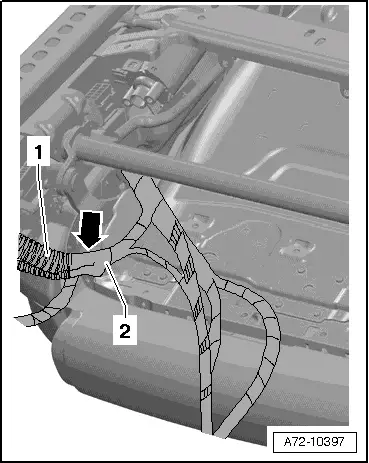

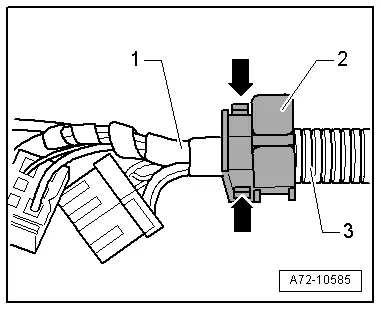

| Unfasten fabric tape -2- in area of -arrow-. |

| –

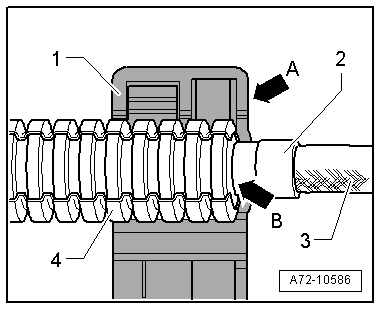

| Open corrugated tube -1-. |

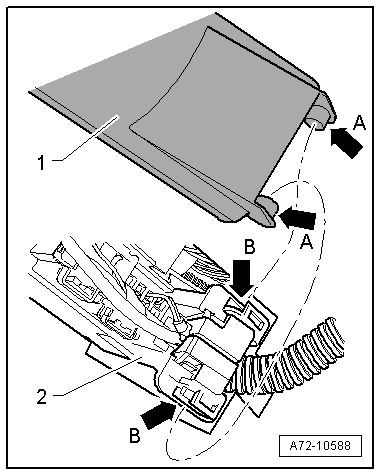

| Fitting individual wires and closing corrugated tube |

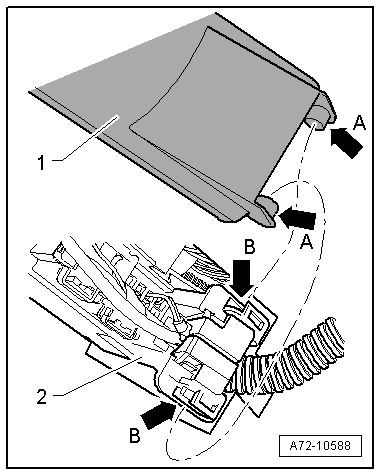

| Install in reverse order of removal. Observe the following: |

WARNING | t

| Observe safety regulations for pyrotechnic components → Chapter. |

| t

| Before handling the airbag units (e.g. unplugging the electrical connector) the mechanic must discharge static electricity by briefly touching the door striker plate, or similar. |

|

| –

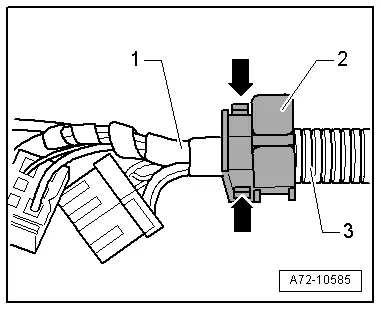

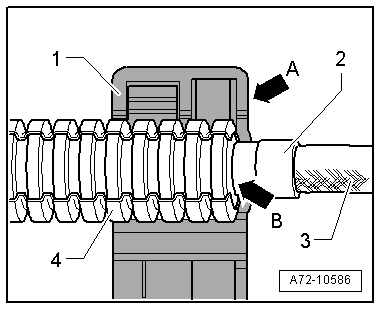

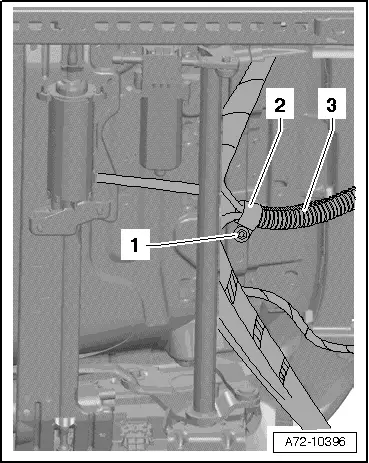

| Take care not to twist any wires when bunching the individual wires and fitting them in the corrugated tube. |

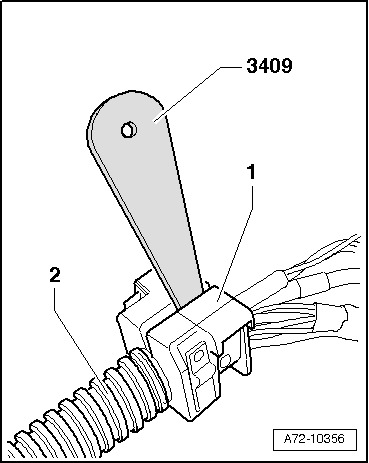

Note | Note the correct installation position of the two-piece corrugated tube in relation to the wiring harness and the cable retainer. |

|

|

|

Note

Note

Note

Note