| –

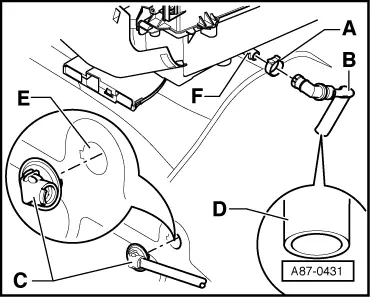

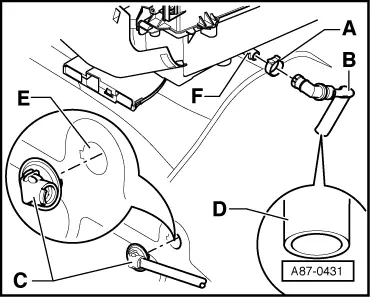

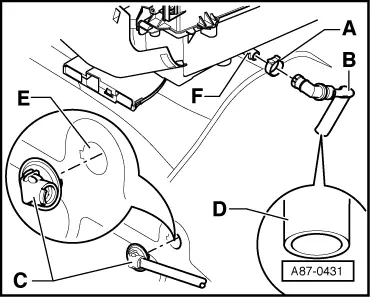

| In area of hole -E- check gap between noise insulation mat and floor panel (noise insulation mat must not make contact with installed condensate drain valve). |

| –

| Check condensate drain valve -C-; it must not be gummed up with wax or underseal. |

Note | There is no flap at the condensate drain valve -C-. The flap function is assumed by a coil formed by the valve. |

| –

| Check for contamination of condensate drain hose -B- (pay attention to oval cross-section of hose -D-) and clean if necessary. |

| –

| Use a piece of wire, for example, to check for contamination of condensate drain of air conditioner unit -F- and clean if necessary. |

| t

| In the event of moisture in the passenger compartment: |

| –

| Check passenger compartment forced air extraction (via luggage compartment) → Chapter. |

| –

| Check signal for recognition of wiper operation at operating and display unit, Climatronic control unit -J255- → Chapter. |

| –

| Check dust and pollen filter for contamination and corresponding cover for correct installation → Chapter. |

| –

| Check the various control motors and the corresponding levers. Pay particular attention to position of air flow flap control motor -V71- and air recirculation flap control motor -V113- as well as the relevant flaps. |

| –

| Check measured value of evaporator outflow temperature sender -G263- → Chapter (Reading measured value block, display group “010”). |

| –

| If the sender measured value is too low under the usage conditions described by the customer (colder than 0 °C for lengthy period at ambient temperature above 0 °C), pay attention to notes on checking cooling output → Chapter. |

| –

| If the measured value of the evaporator outflow temperature sender -G263- is too high under the usage conditions described by the customer (greater than e.g. 10 °C although air conditioner is functioning properly), check the evaporator outflow temperature sender -G263- (incorrect measured value can cause evaporator to ice up). |

|

|

|

Note

Note

Note

Note