A4 Mk2

|

| 1 - | Bolt |

| q | 22 Nm |

| q | Observe instructions for installation → Chapter |

| 2 - | Pressure plate |

| q | Self-adjusting |

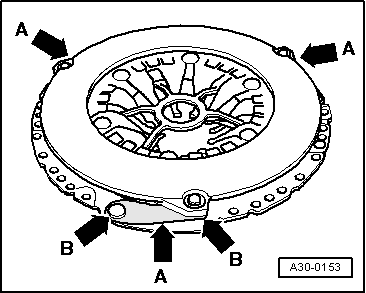

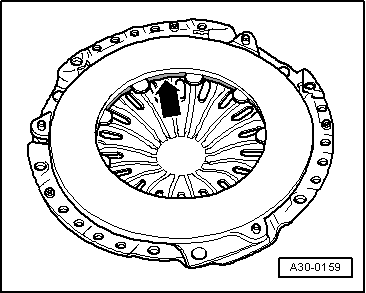

| q | Identification → Fig. |

| q | Pressure plate and clutch plate can only be renewed together. |

| q | Removing and installing → Chapter |

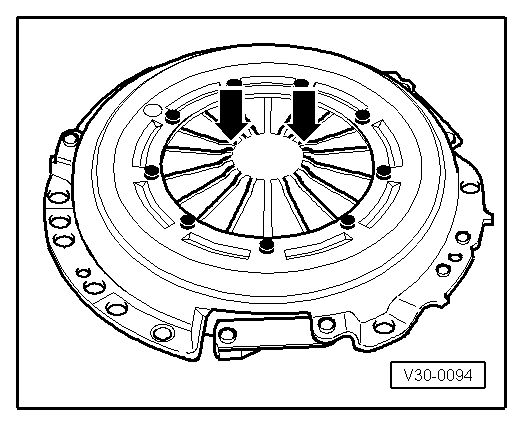

| q | Checking ends of diaphragm spring → Fig. |

| q | Checking spring connection and rivets → Fig. |

| q | Checking wire ring → Fig. |

| 3 - | Clutch plate |

| q | Pressure plate and clutch plate can only be renewed together. |

| q | Installation position: Clutch lining must make full contact with flywheel |

| q | The marking “Getriebeseite” (gearbox side), if provided, faces towards pressure plate/gearbox. |

| q | If fitted, coil springs (damper assembly) face towards pressure plate and gearbox |

| q | Centralising → Anchor |

| q | Lightly grease splines → Anchor |

| q | Select diameter of clutch plate according to engine code → Electronic parts catalogue. |

| 4 - | Bolt for flywheel |

| q | Always renew |

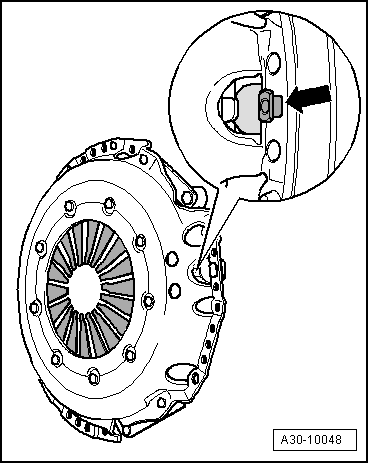

| q | Observe instructions for removal → Fig. |

| q | Bolt length: 22.5 mm; 60 Nm + 90° further |

| q | Bolt length: 43 mm; 60 Nm + 180° further |

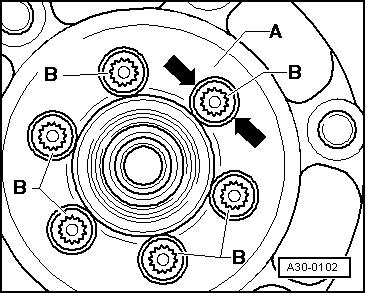

| 5 - | Dual-mass flywheel |

| q | Ensure that dowel pins fit tightly |

| q | Contact surface for clutch lining must be free of grooves, oil and grease |

| q | Observe instructions for removal → Fig. |

| 6 - | Needle bearing |

| q | Removing and installing → Rep. Gr.13 |

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Caution

Caution