A4 Mk2

| Removing gearbox on vehicles with 4-cylinder engine |

| Special tools and workshop equipment required |

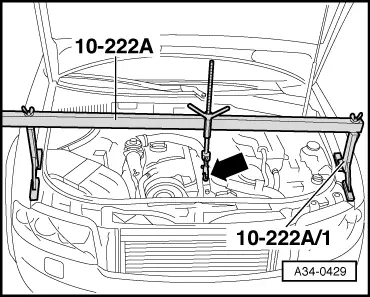

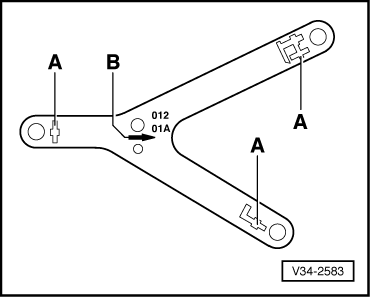

| t | Support bracket -10 - 222 A- |

| t | Lifting tackle -2024 A- |

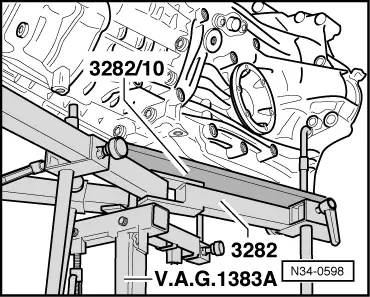

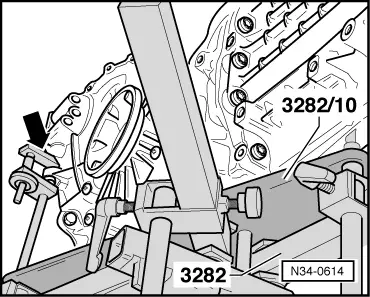

| t | Gearbox support -3282- |

| t | Adjustment plate -3282/10- |

| t | Engine and gearbox jack -V.A.G 1383 A- |

| t | Grease for clutch plate splines -G 000 100- |

| t | Copper grease -Z 381 351 TE- |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

Note

Note

|

|

|

|

WARNING

WARNING