| l

| The gear lever should rest in the 3rd/4th gear gate when the gearbox is in neutral. |

| –

| Check that all gears can be engaged. |

| l

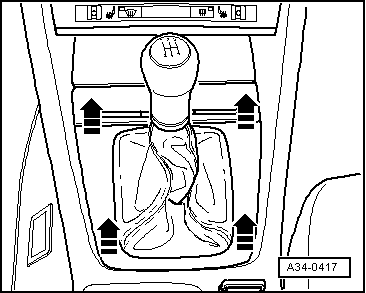

| When changing through the gears the gear lever must not touch the centre console cover. |

| l

| The gear lever should return by itself from the 5th/reverse gate into the 3rd/4th gate. |

| l

| It should only be possible to engage reverse gear after moving the gear lever into the 3rd/4th gate in neutral. |

| l

| It should not be possible to select reverse gear directly from 5th gear. |

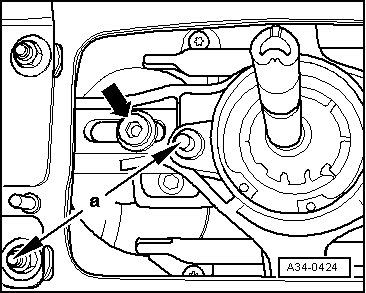

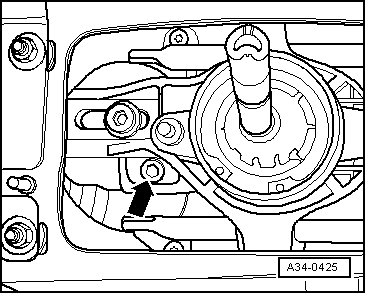

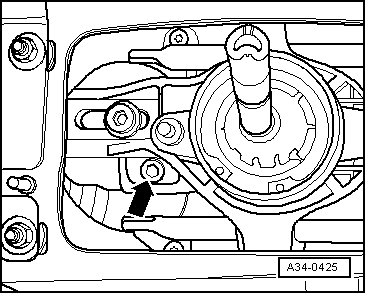

Note | If it is possible to select reverse gear directly from 5th gear, or if only 5th gear and reverse cannot be engaged, the locking unit for 5th and reverse gear should be checked and if necessary renewed → . |

|

|

|

Note

Note

Note

Note

Note

Note