A4 Mk2

|

|

|

|

|

|

|

|

|

|

|

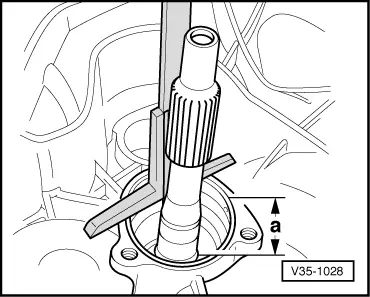

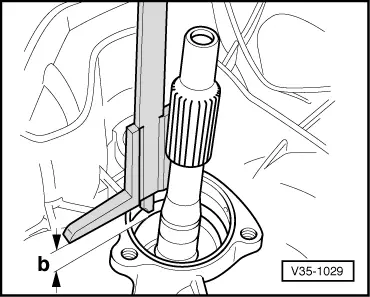

| Example: | ||

| Dimension “a” | 28.50 mm | |

| – | Dimension “b” | 26.80 mm |

| = | Dimension “x” (thickness of circlip) | 1.70 mm |

|

| Dimension “x” | Thickness (mm) |

| 1.48…1.56 | 1.54 |

| 1.57…1.65 | 1.63 |

| 1.66…1.74 | 1.72 |

| 1.75…1.83 | 1.81 |

| 1.84…1.92 | 1.90 |

| 1.93…2.01 | 1.99 |

| 2.02…2.10 | 2.08 |

| 2.11…2.20 | 2.17 |

| 2.21…2.27 | 2.25 |

| 2.28…2.35 | 2.33 |

|

|

|

| Circlip thickness (mm) | ||

| 1.45 | 1.72 | 1.99 |

| 1.54 | 1.81 | 2.08 |

| 1.63 | 1.90 | 2.17 |