A4 Mk2

|

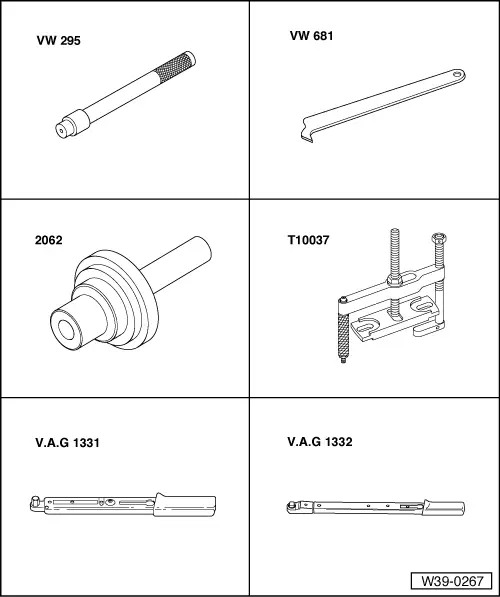

| Special tools and workshop equipment required |

| t |

| t | Drift -VW 295- |

| t | Release lever -VW 681- |

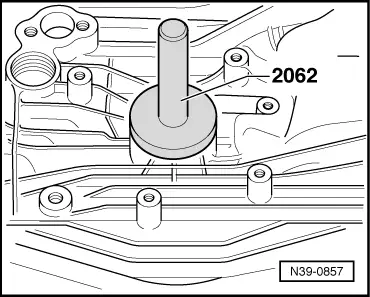

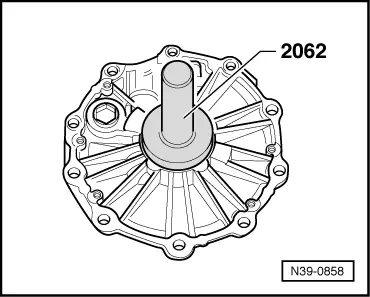

| t | Punch -2062- |

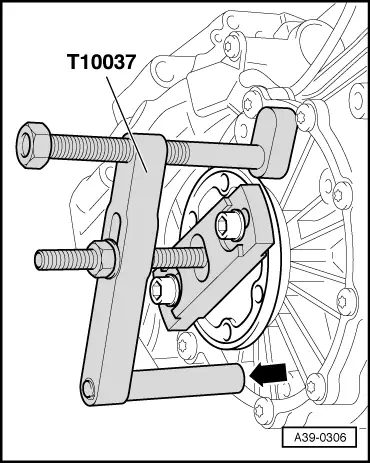

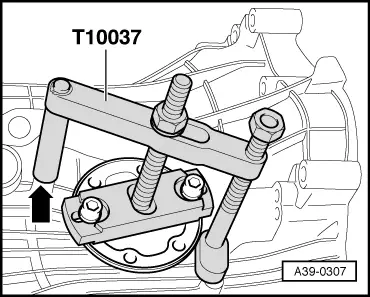

| t | Puller -T10037- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

|

|

| Component | Nm | |

| Drive shaft heat shields | 23 | |