| –

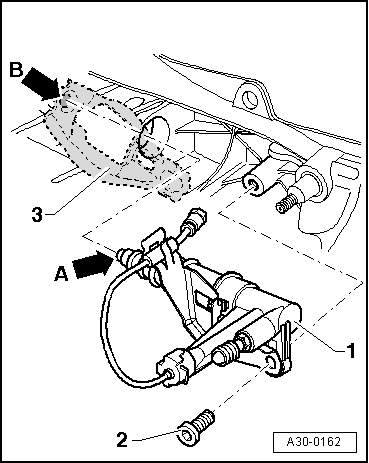

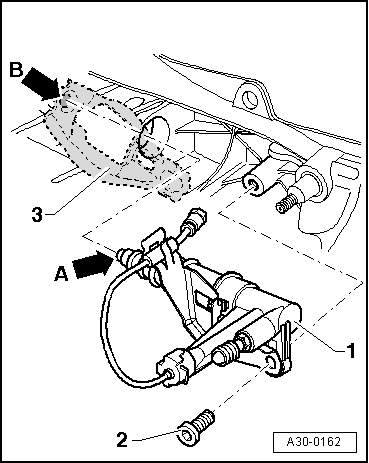

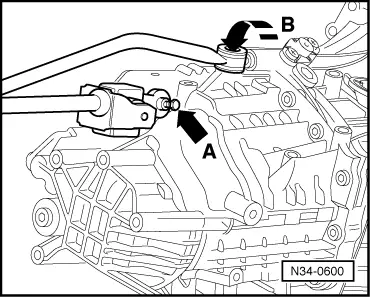

| Using copper grease -Z 381 351 TE-, lightly lubricate surface where plunger makes contact with clutch release lever -arrow B-. |

| –

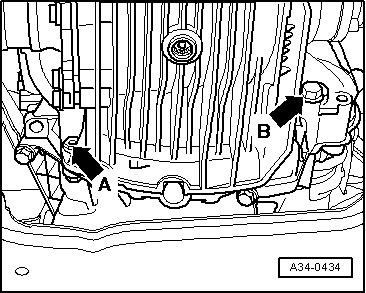

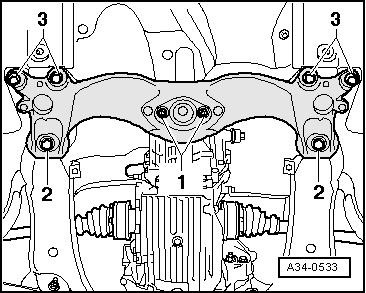

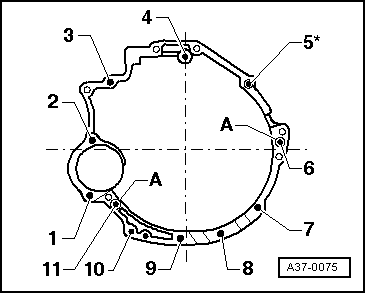

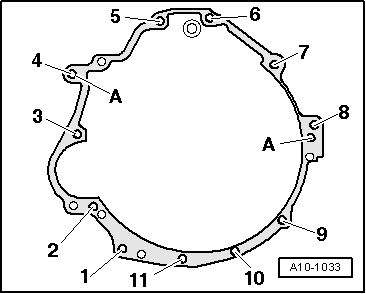

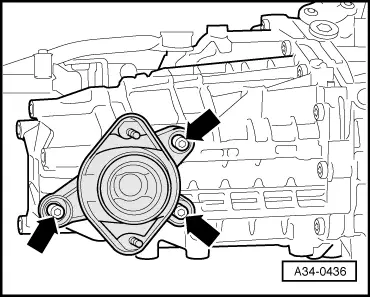

| Raise gearbox far enough to be able to install clutch slave cylinder with bracket for pipe/hose assembly. |

| –

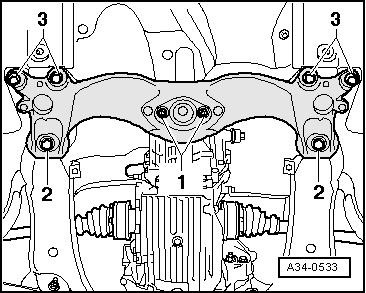

| Guide slave cylinder -1- into opening in gearbox housing, keeping it as straight as possible (without tilting plunger -arrow A-), and insert in recess -arrow B- on clutch release lever -3-. |

Note | If the slave cylinder -1- is inserted at an angle, there is a danger that the plunger -arrow A- will be guided past the clutch release lever -3-. |

| –

| Secure slave cylinder with new bolt -2-. |

| –

| When aligning the gearbox with the engine, turn crankshaft back and forth slightly to make it easier to insert the gearbox input shaft splines into the clutch plate. |

Caution | t

| After installing the slave cylinder press the clutch pedal carefully. |

| t

| If you feel an unusually strong point of resistance when depressing the clutch pedal, you must not press it down further. |

| t

| The plunger of the slave cylinder is likely to have been guided past the clutch release lever. |

| t

| The slave cylinder would then be destroyed once pedal force exceeds approx. 300 N. |

| t

| For comparison: normal pedal force is approx. 115 N. |

|

|

|

|

Note

Note Note

Note

Note

Note

Caution

Caution