| t

| After installing a replacement gearbox, check oil level and fill up with gear oil as required → Chapter. |

| t

| Thoroughly clean all joints and surrounding areas before dismantling. |

| t

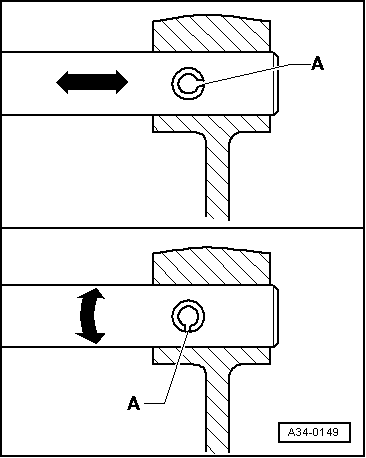

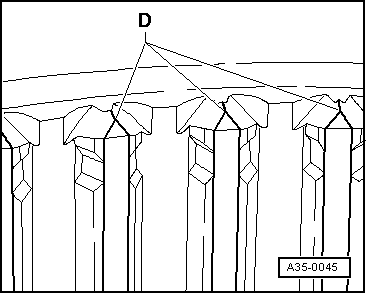

| When installing gearbox ensure dowel sleeves are correctly seated. |

| O-rings, oil seals, gaskets |

| t

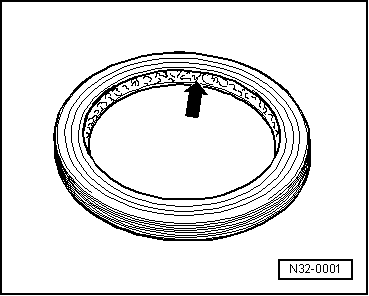

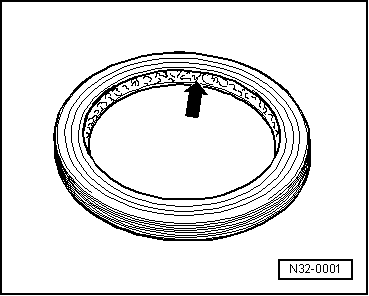

| Always install new O-rings, oil seals and gaskets. |

| t

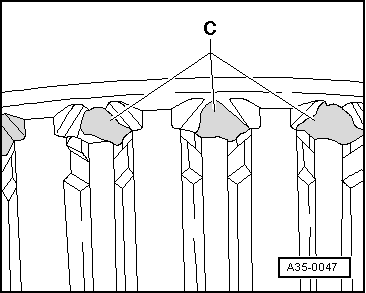

| After removing gaskets and seals, always inspect the contact surface on the housing or shaft for burrs resulting from removal or for other signs of damage. |

| t

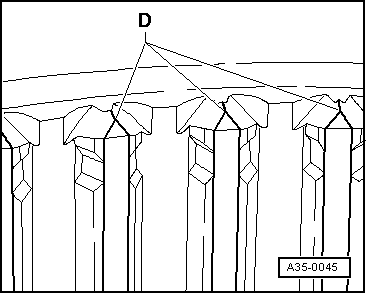

| Thoroughly clean housing joint surfaces before assembling. |

|

|

|

Note

Note

Note

Note