A4 Mk2

| Renewing oil seal and grooved ball bearing for flange for propshaft on gearbox |

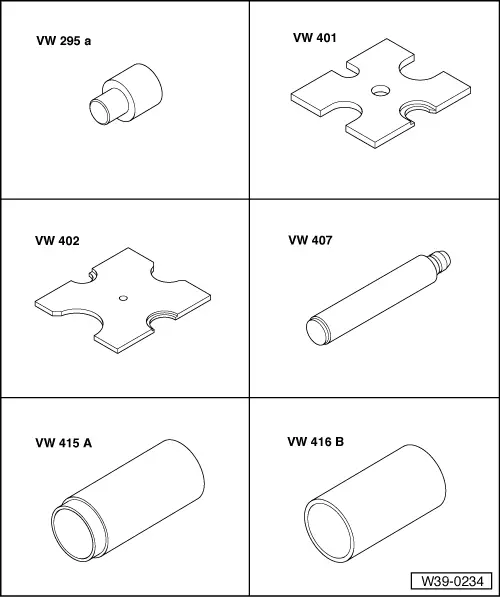

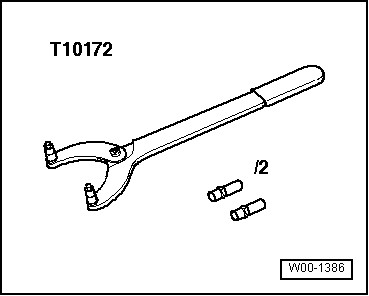

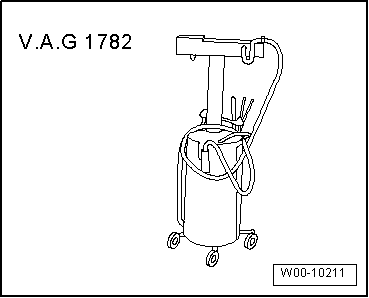

| Special tools and workshop equipment required |

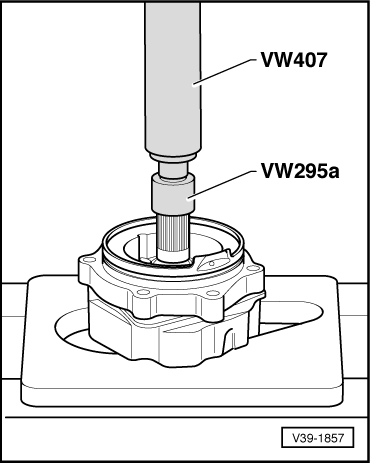

| t | Adapter -VW 295 A- |

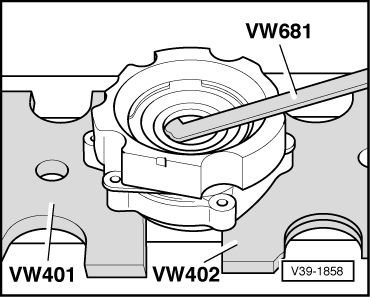

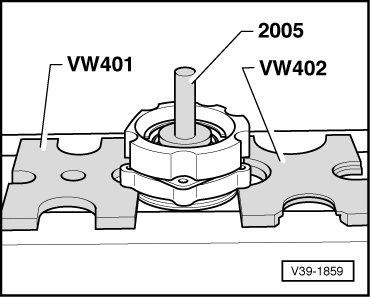

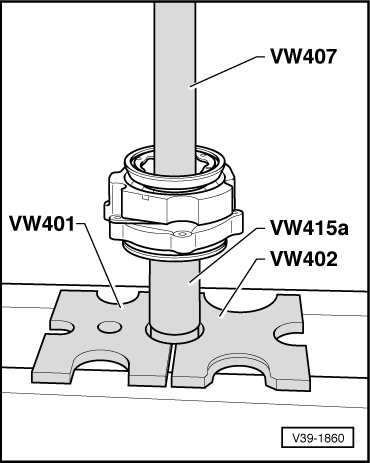

| t | Thrust plate -VW 401- |

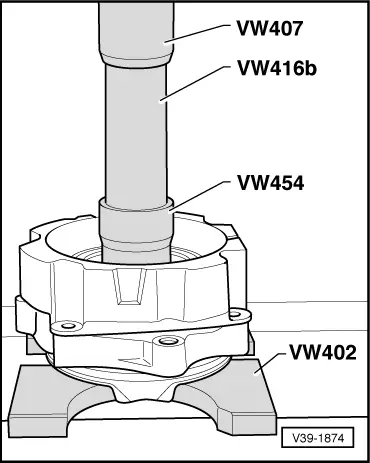

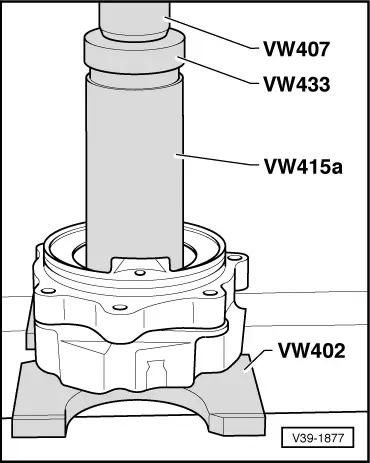

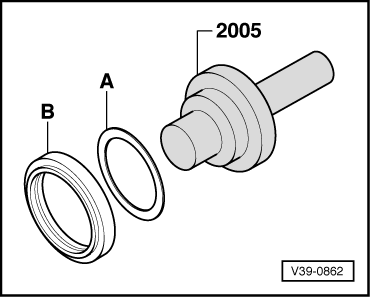

| t | Thrust plate -VW 402- |

| t | Press tool -VW 407- |

| t | Tube -VW 415 A- |

| t | Tube -VW 416 B- |

| t | Press tool -VW 433- |

| t | Press tool - VW 454- |

| t | Oil seal extractor lever -VW 681- |

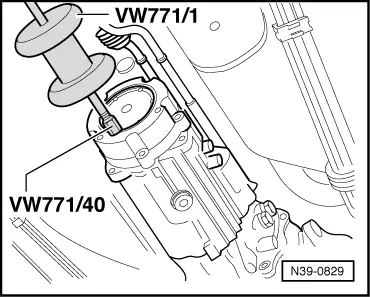

| t | Multi-purpose tool -VW 771- |

| t | Punch -2005- |

| t | Torque wrench -V.A.G 1331- |

| t | Shim -016 311 391 B- |

|

|

|

|

|

|

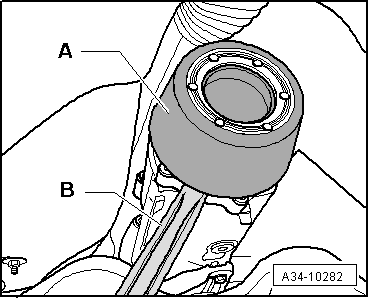

| Exploded view |

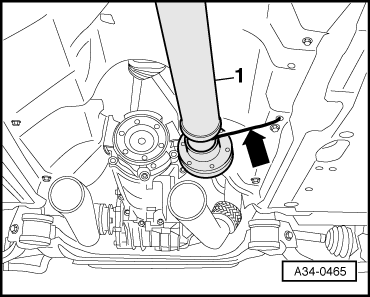

| 1 - | Gearbox |

| 2 - | Grooved ball bearing |

| 3 - | Bearing housing |

| q | With damper weight (depending on version) |

| 4 - | Oil seal |

| q | Driving in → Anchor |

| 5 - | Flange shaft |

| q | On vehicles with 4-cyl. TDI engine and vibration damper → Anchor |

| 6 - | Bolt, 25 Nm |

| q | 6x |

| 7 - | O-ring |

| q | Renew |

| 8 - | Circlip |

| 9 - | Dished spring |

| q | Mark installation position when removing: larger diameter (concave side) towards shims → Item |

| 10 - | Shims |

| 11 - | Spring |

| 12 - | Oil drain plug, 40 Nm |

Note

Note |

Note

Note

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|