A4 Mk2

| Re-determining thickness of shim “S4” |

| This adjustment is necessary when the following components are renewed: |

| t | Intermediate housing → Anchor |

| t | Hollow shaft → Anchor |

| t | Tapered roller bearing of pinion shaft/hollow shaft → Anchor |

| This adjustment restores the required preload of the tapered roller bearings for the pinion shaft and hollow shaft. |

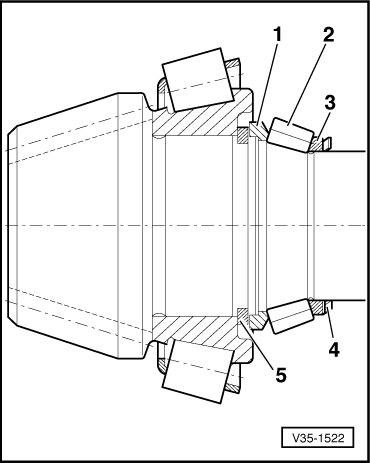

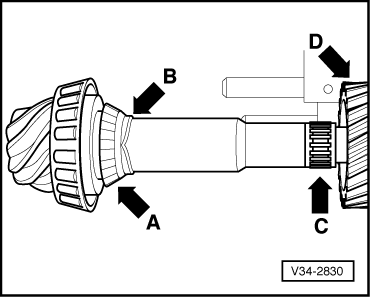

| 1 - | Shim “S4” |

| 2 - | Intermediate housing |

| q | If renewing, re-determine shim “S4” |

| 3 - | Gearbox housing |

| 4 - | Hollow shaft |

| q | If renewing, re-determine shim “S4” |

| 5 - | Tapered roller bearing of pinion shaft/hollow shaft |

| q | Arrangement and components → Anchor |

| q | If renewing, re-determine shim “S4” |

| 6 - | Pinion shaft |

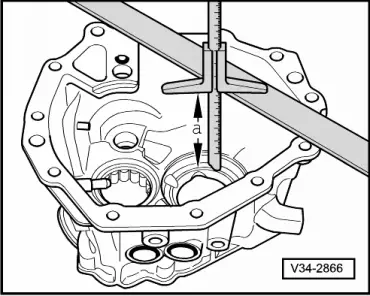

| a - | Intermediate housing depth |

| b - | Dimension from pinion gear to contact shoulder of tapered roller bearing on hollow shaft |

| q | Tapered roller bearing (pinion shaft/hollow shaft) preloaded to 10 Nm → Anchor |

| S4 - | Thickness of shim “S4” |

Note

Note| Refer to table of adjustments → Anchor when renewing the pinion shaft (final drive set). |

|

|

|

|

|

|

|

| Example: | |

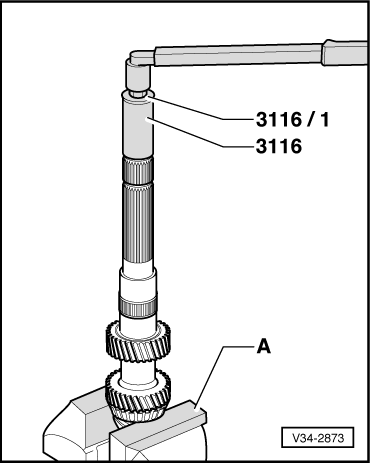

| Depth -a- (old intermediate housing) | 124.40 mm |

| Depth -a- (new intermediate housing) | 124.65 mm |

| Difference | = 0.25 mm |

|

| Example: | |

| Previous “S4” shim | 0.95 mm |

| Difference | + 0.25 mm |

| New “S4” shim | = 1.20 mm |

|

|

|

|

|

|

|

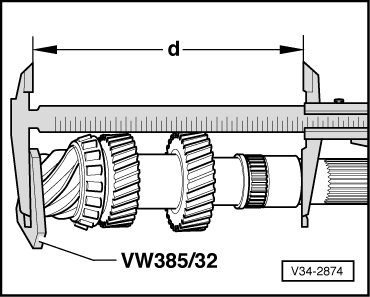

| Example: | |

| Dimension -d-, old hollow shaft | 248.50 mm |

| Dimension -d-, new hollow shaft | 248.70 mm |

| Difference | = 0.20 mm |

|

| Available shims - Thickness of shims in mm 1)2) | ||||||

| 0.45 | 0.65 | 0.85 | ||||

| 0.50 | 0.70 | 0.90 | ||||

| 0.55 | 0.75 | |||||

| 0.60 | 0.80 | |||||

| ||||||