A4 Mk2

| Servicing end cover |

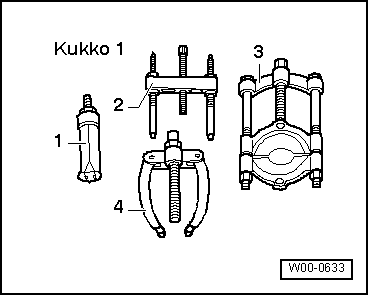

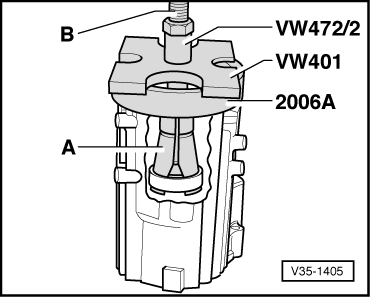

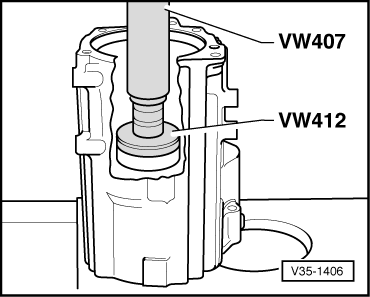

| Special tools and workshop equipment required |

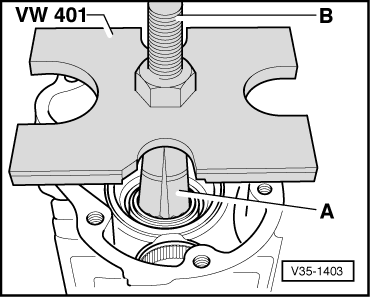

| t | Thrust plate -VW 401- |

| t | Thrust plate -VW 402- |

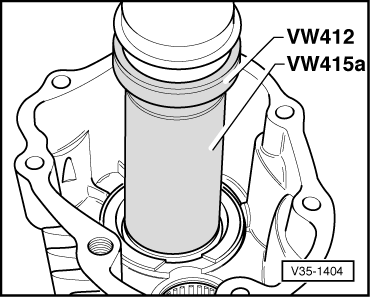

| t | Press tool -VW 412- |

| t | Tube -VW 415 A- |

| t | Spacer sleeve -VW 472/2- |

| t | Thrust ring -2006 A- |

|

|

|

|

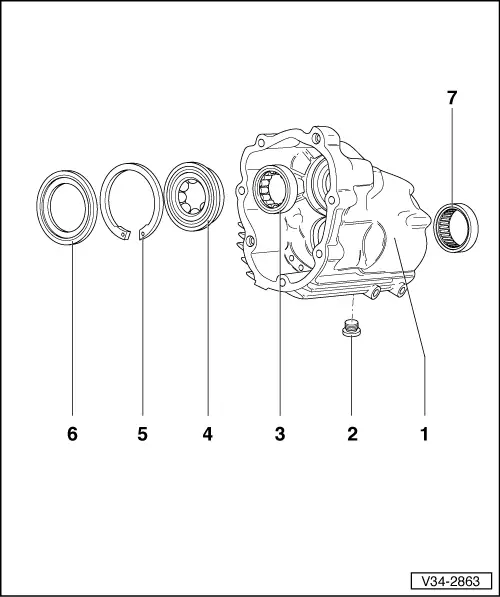

| Exploded view |

| 1 - | End cover |

| q | If renewed, re-determine thickness of circlip → Item |

| q | Re-determine shims for Torsen differential → Anchor |

| 2 - | Oil drain plug, 40 Nm |

| 3 - | Roller bearing for input shaft |

| q | Pulling out → Fig. |

| q | Pressing in flush → Fig. |

| 4 - | Ball bearing for input shaft |

| q | Removing → Fig. |

| q | Installing → Fig. |

| q | If renewed, re-determine thickness of circlip → Item |

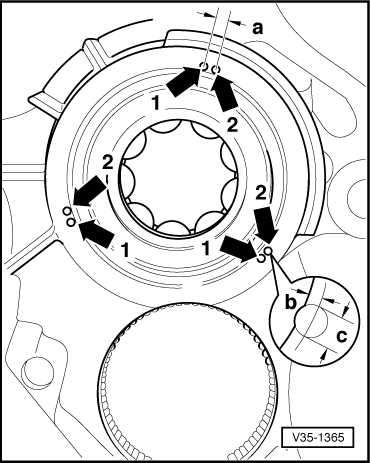

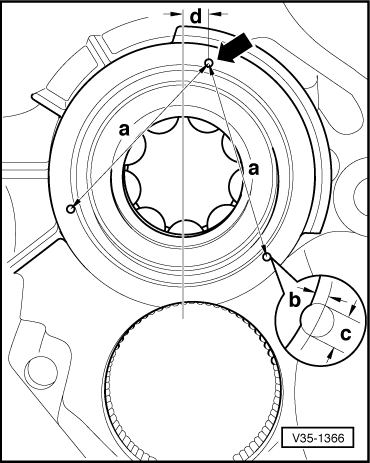

| 5 - | Circlip |

| q | Re-determining thickness → Anchor |

| q | Installing → Fig. |

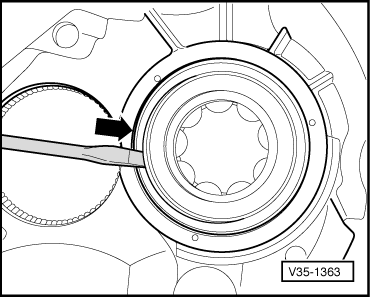

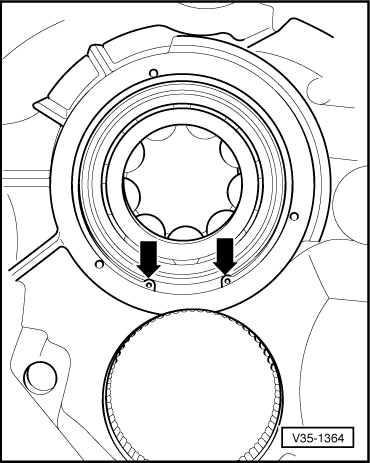

| 6 - | Baffle plate |

| q | Renew |

| q | Removing → Fig. |

| q | Installing and peening in position when renewing ball bearing for input shaft → Fig. |

| q | Installing and peening in position when renewing end cover → Fig. |

| 7 - | Needle bearing for Torsen differential |

| q | Pulling out → Fig. |

| q | Driving in → Fig. |

|

|

|

|

Note

Note

|

|

| Available circlips - Thickness in mm 1) | |||

| 2.55 | 2.65 | ||

| 2.60 | 2.70 | ||

| |||

|

|

|

|

|

|

|

|

|