A4 Mk2

| Removing gearbox - vehicles with 4-cyl. petrol engine |

| Special tools and workshop equipment required |

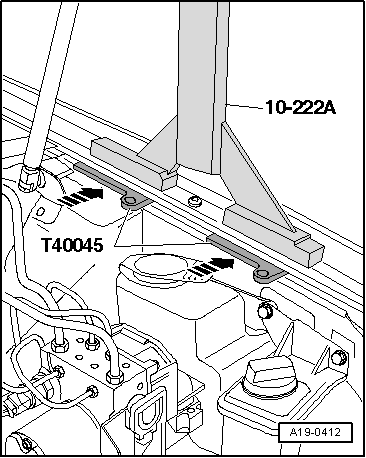

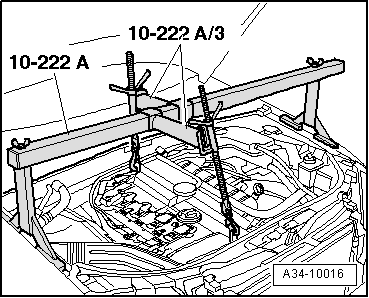

| t | Support bracket -10-222 A- |

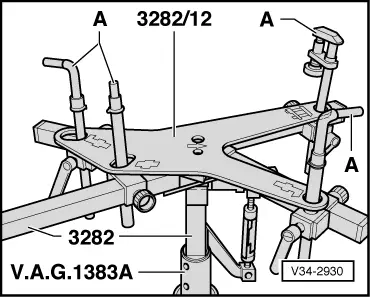

| t | Gearbox support -3282- |

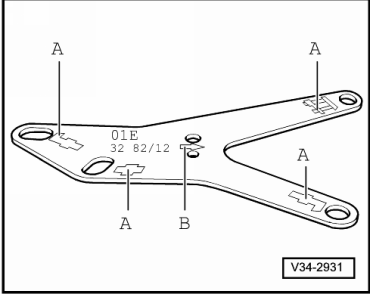

| t | Adjustment plate -3282/43- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

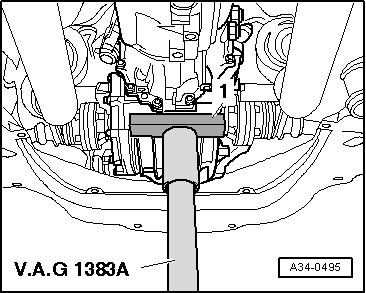

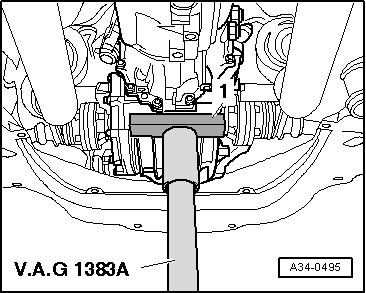

| t | Engine and gearbox jack -V.A.G 1383 A- |

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note |

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Caution

Caution