A4 Mk2

| Adjusting crown wheel |

| (Adjusting differential) |

| Special tools and workshop equipment required |

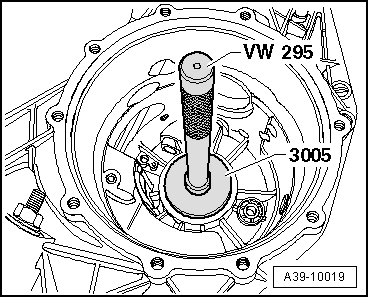

| t | Drift -VW 295- |

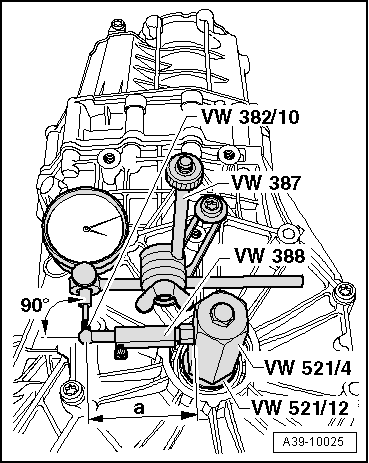

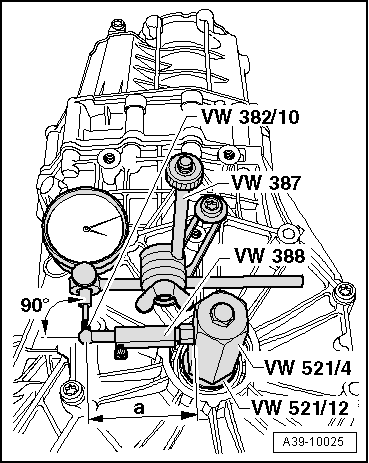

| t | Dial gauge extension -VW 382/10- |

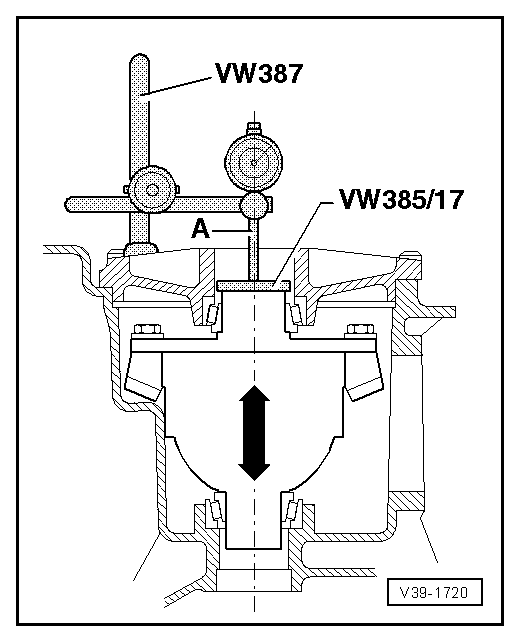

| t | End measuring plate -VW 385/17- |

| t | Universal dial gauge bracket -VW 387- |

| t | Adjustable measuring lever -VW 388- |

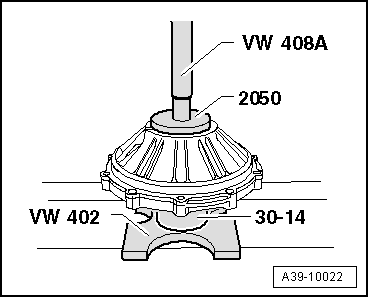

| t | Thrust plate -VW 402- |

| t | Press tool -VW 408 A- |

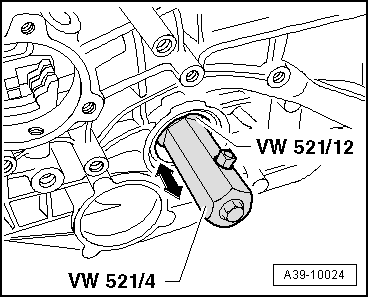

| t | Crown wheel adjusting tool -VW 521- |

| t | Tube -30 - 14- |

| t | Thrust piece -2050- |

| t | Thrust plate -3005- |

| t | Torque wrench -V.A.G 1331- |

| t | Dial gauge |

| t | Dial gauge extension, 30 mm |

|

Note

Note

|

|

|

|

Note

Note

Note

Note |

|

|

|

| Example: | ||

| Inserted shim(s) “S2*” | 1.30 mm | |

| + | Measured value | 0.62 mm |

| + | Bearing preload (constant value) | 0.25 mm |

| = | Total shim thickness “Stotal” for “S1” plus “S2” | 2.17 mm |

Note

Note

|

| Example: | ||

| Total shim thickness “Stotal” for “S1” plus “S2” | 2.17 mm | |

| – | Inserted shim(s) “S2*” | 1.30 mm |

| = | Thickness of shim “S1*” | 0.87 mm |

|

Note

Note |

|

|

|

| Example: | ||

| 1st measured value | 0.28 mm | |

| + | 2nd measured value | 0.30 mm |

| + | 3rd measured value | 0.30 mm |

| + | 4th measured value | 0.28 mm |

| = | Sum of measured values | 1.16 mm |

Note

Note

|

| Example: | ||

| Inserted shim “S2*” | 1.30 mm | |

| – | Measured average backlash | 0.29 mm |

| + | Specified backlash (desired average value for backlash) | 0.20 mm |

| = | Thickness of shim “S2” | 1.21 mm |

|

| Shim thickness (mm) 1) | ||

| 0.45 | 0.61 | 0.77 |

| 0.49 | 0.65 | 0.81 |

| 0.53 | 0.69 | 0.85 |

| 0.57 | 0.73 | |

| 1) The exact shim thickness required can be obtained by using the shim tolerance variations. Install two shims if necessary. | ||

|

| Example: | ||

| Total shim thickness “Stotal” for “S1” plus “S2” | 2.17 mm | |

| – | Thickness of shim “S2” | 1.21 mm |

| = | Thickness of shim “S1” | 0.96 mm |

|

| Shim thickness (mm) 1) | ||

| 0.45 | 0.61 | 0.77 |

| 0.49 | 0.65 | 0.81 |

| 0.53 | 0.69 | 0.85 |

| 0.57 | 0.73 | |

| 1) The exact shim thickness required can be obtained by using the shim tolerance variations. Install two shims if necessary. | ||

Note

Note

|

|