A4 Mk2

| Adjusting pinion shaft |

| Repairs after which the pinion shaft must be adjusted → Chapter. |

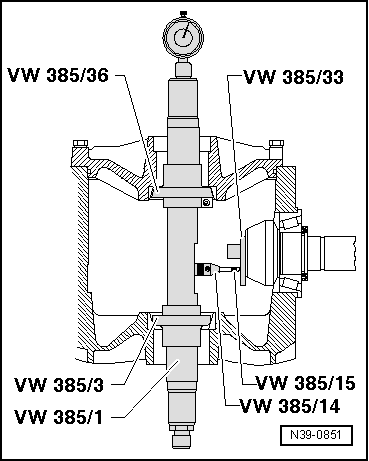

| Special tools and workshop equipment required |

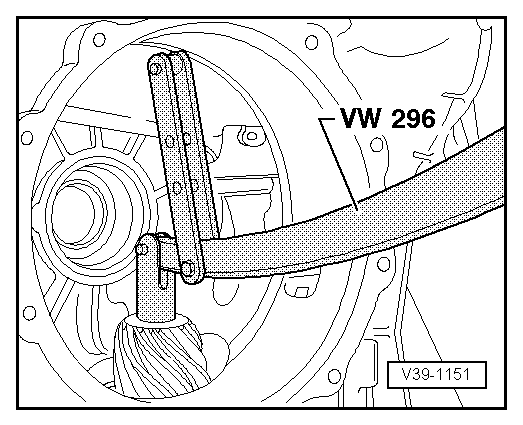

| t | Transmission removal lever -VW 296- |

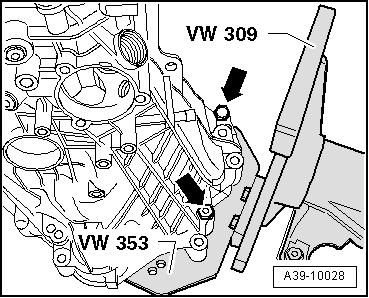

| t | Support plate -VW 309- |

| t | Gearbox support -VW 353- |

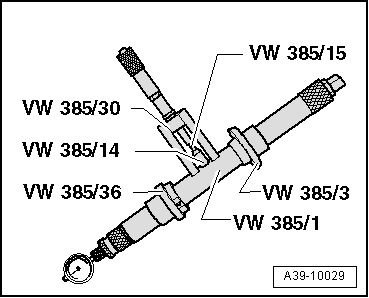

| t | Universal measuring tool -VW 385- |

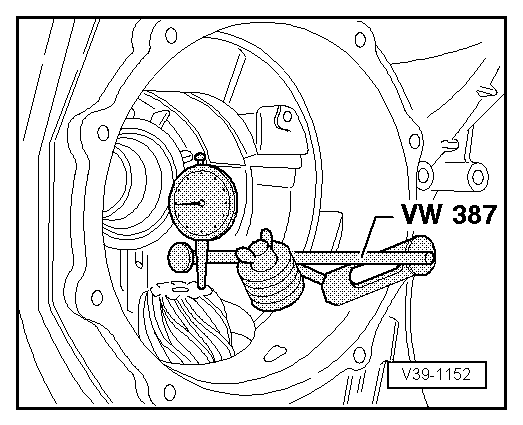

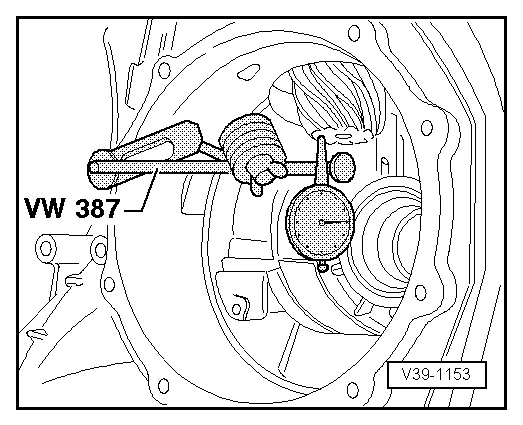

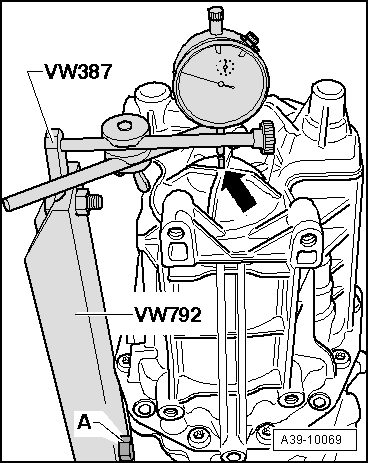

| t | Universal dial gauge bracket -VW 387- |

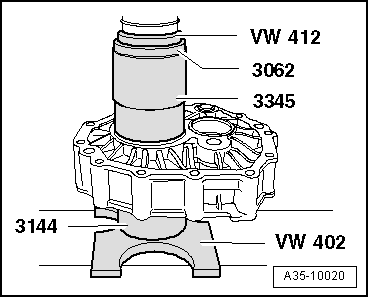

| t | Thrust plate -VW 402- |

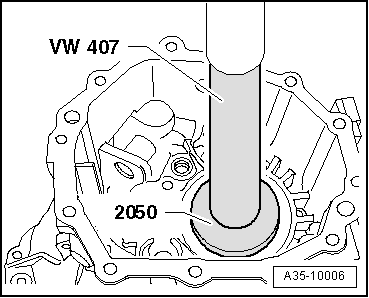

| t | Press tool -VW 407- |

| t | Press tool -VW 412- |

| t | Assembly device -VW 792- |

| t | Thrust piece -2050- |

| t | Thrust pad -3062- |

| t | Sleeve -3144- |

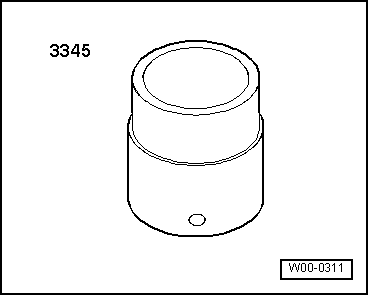

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

| Example: | ||

| Inserted shim “S4*” | 1.01 mm | |

| + | Measured value (example) | 0.46 mm |

| + | Bearing preload (constant value) | 0.12 mm |

| = | Total shim thickness “Stotal” for “S3” plus “S4” | 1.59 mm |

|

| Example: | ||

| Total shim thickness “Stotal” for “S3” plus “S4” | 1.59 mm | |

| – | Inserted shim “S4*” | 1.01 mm |

| = | Thickness of shim “S3*” | 0.58 mm |

|

Note

Note

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

| Example: | ||

| Inserted shim “S3*” | 0.58 mm | |

| + | Allowance “r” | 0.29 mm |

| – | Determined value “e” (in red scale) | 0.17 mm |

| = | Thickness of shim “S3” | 0.70 mm |

|

| Shim thickness (mm) 1) | ||

| 0.53 | 0.85 | 1.17 |

| 0.57 | 0.89 | 1.21 |

| 0.61 | 0.93 | 1.25 |

| 0.65 | 0.97 | 1.29 |

| 0.69 | 1.01 | 1.33 |

| 0.73 | 1.05 | 1.37 |

| 0.77 | 1.09 | 1.41 |

| 0.81 | 1.13 | |

| 1) The exact shim thickness required can be obtained by using the shim tolerance variations. Install two shims if necessary. | ||

|

| Example: | ||

| Total shim thickness “Stotal” for “S3” plus “S4” | 1.59 mm | |

| – | Thickness of shim “S3” | 0.70 mm |

| = | Thickness of shim “S4” | 0.89 mm |

|

| Shim thickness (mm) 1) | ||

| 0.33 | 0.73 | 1.13 |

| 0.37 | 0.77 | 1.17 |

| 0.41 | 0.81 | 1.21 |

| 0.45 | 0.85 | 1.25 |

| 0.49 | 0.89 | 1.29 |

| 0.53 | 0.93 | 1.33 |

| 0.57 | 0.91 | 1.37 |

| 0.61 | 1.01 | 1.41 |

| 0.65 | 1.05 | 1.45 |

| 0.69 | 1.09 | 1.49 |

| 1) The exact shim thickness required can be obtained by using the shim tolerance variations. Install two shims if necessary. | ||

|

|

|