| –

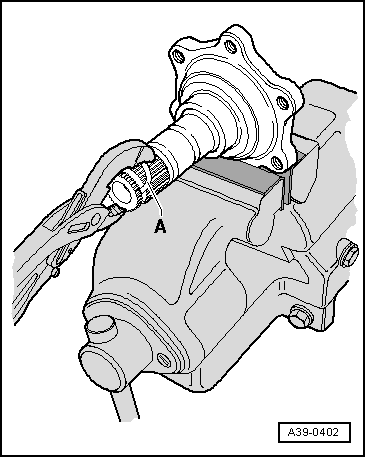

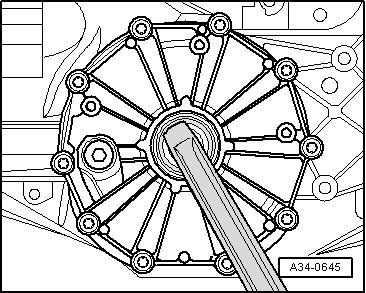

| Lightly oil outer circumference of new oil seal. |

| –

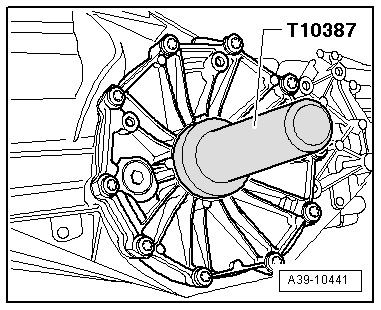

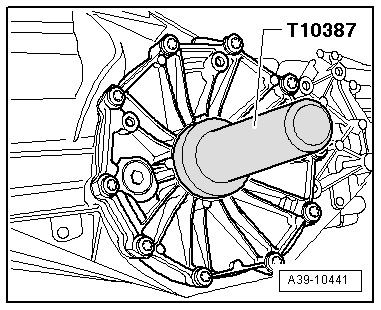

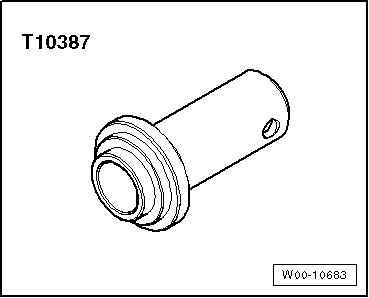

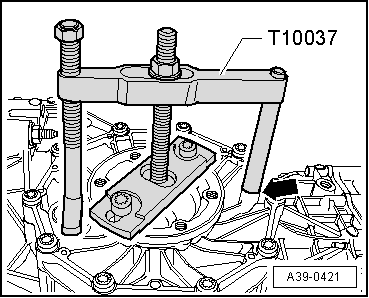

| Drive in new flange shaft oil seal using thrust piece -T10387- until thrust piece reaches stop; keep seal straight when installing. |

Note | t

| Driving-in depth (standard): 5.5 mm beneath surface of cover |

| t

| When carrying out a repair, the oil seal is driven in to a depth of 6.5 mm using thrust piece -T10387-, so that the new seal does not bear on the same contact surface on the used flange shaft. |

| –

| Pack space between sealing lip and dust lip half-full with sealing grease -G 052 128 A1-. |

Note |

|

|

Note

Note Note

Note